Best Ceramic Sleeves Manufacturer in Germany

A premier ceramic sleeves manufacturer in Germany represents a global benchmark for quality. These manufacturers are foundational to industries where precision is not just a goal, but a requirement. Ceramic sleeves are small, high-precision components. They are the unseen heroes in fiber optic networks, medical devices, and advanced aerospace systems. Their performance dictates the reliability of our digital world.

The market for ceramic sleeves Europe is defined by its demand for perfection. Manufacturers in this region are known for their engineering heritage. They combine advanced material science with sub-micron manufacturing tolerances. This article will explore what defines the "best" in this field. We will cover the materials, the processes, and the quality systems. These elements separate a top-tier manufacturer from the rest. For a complete overview of the component, a ceramic sleeves guide offers a useful starting point.

What Are High-Precision Ceramic Sleeves?

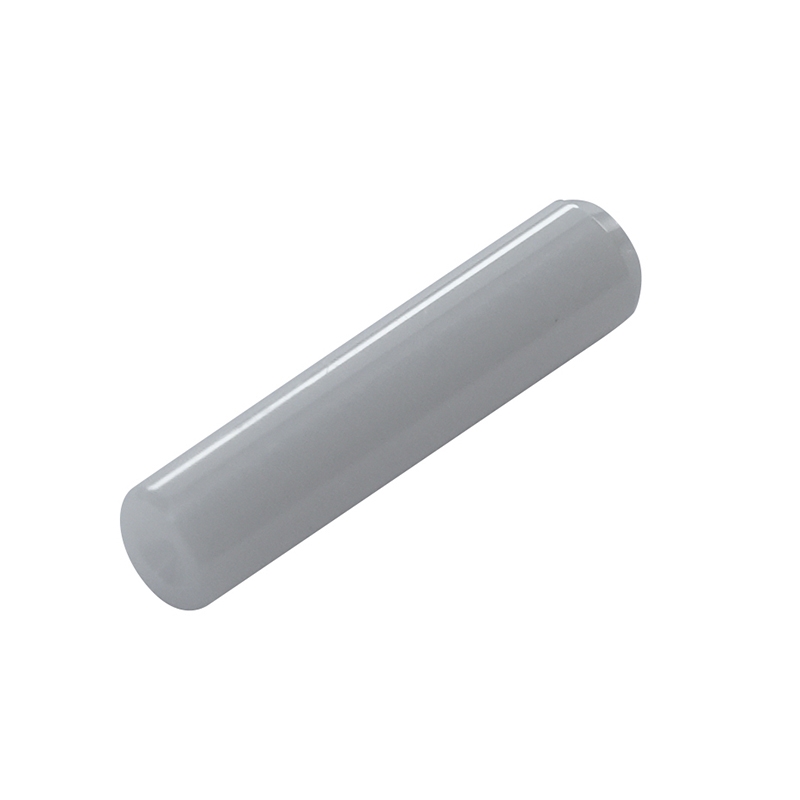

A ceramic sleeve is a small, cylindrical tube. Its primary function is to provide precise alignment for other components. In its most common application, fiber optics, it aligns two hair-thin fiber cores. This ensures that light passes from one fiber to the other with minimal loss. This signal loss is known as insertion loss. A high-quality sleeve is the most critical factor in achieving a low-loss connection.

The Material: Why Zirconia is Essential

The performance of a ceramic sleeve is determined by its material. The industry standard is Yttria-Stabilized Zirconia (Y-TZP). This is not a typical ceramic. It is an advanced engineering material.

A top ceramic sleeves manufacturer in Germany uses zirconia for its unique properties:

- Extreme Hardness: Zirconia is harder than steel. It resists wear from repeated connections.

- High Fracture Toughness: Unlike most ceramics, Y-TZP is not brittle. It can absorb impact and resist cracking.

- Low Thermal Expansion: The material does not change size with temperature. This is vital for stable connections in hot data centers or cold outdoor equipment.

- Chemical Inertness: It does not rust, corrode, or react to moisture.

- Smooth Surface: It can be polished to a mirror-like finish. This prevents it from scratching the fiber end-face.

These properties ensure a sleeve can perform for decades. It will provide a stable, reliable connection over thousands of uses.

Split vs. Solid Sleeves

Ceramic sleeves are produced in two main types.

- Split Sleeves: This is the most common type. It features a narrow, vertical slit down one side. This slit allows the sleeve to compress slightly. It gently but firmly grips the ferrule. This ensures a secure fit even with tiny variations in ferrule diameter.

- Solid Sleeves: These are solid-bore tubes with no slit. They provide a rigid, non-flexing alignment. They are often used inside active devices like transceivers.

A top manufacturer has mastery over both designs. They can produce both with the same high level of precision.

The Hallmarks of German Precision Engineering

The term "German engineering" is not just a label. It is a philosophy of quality. It is built on a commitment to technical excellence. For a ceramic sleeves manufacturer in Germany, this means focusing on factors that others may overlook.

Sub-Micron Tolerances

The most critical specification for a sleeve is its dimensions. We are not talking about millimeters. We are talking about microns. A micron is one-thousandth of a millimeter. A human hair is about 70 microns wide.

A premier manufacturer controls its inner diameter (ID) to a tolerance of ±0.0005 mm. That is half a micron. This extreme precision ensures that the fiber core is perfectly centered. This is what separates an average sleeve from a high-performance one.

Commitment to Material Purity

The process starts with the raw material. A top manufacturer uses only the highest-purity Y-TZP powder. Any impurity in the initial mix can lead to a weak spot in the final product. This could cause a micro-crack or a surface imperfection. A commitment to pure materials is the first step in a quality product.

Advanced Quality Control

You cannot create precision parts without measuring them. A top ceramic sleeves manufacturer in Germany invests heavily in metrology.

- Laser Micrometers: These non-contact tools measure the outer diameter.

- Air Gauges: These specialized tools measure the inner diameter. They blow a precise amount of air through the sleeve. The system measures the back pressure to calculate the ID to sub-micron accuracy.

- Video Inspection Systems: High-resolution cameras scan 100% of parts. They look for tiny cracks, chips, or surface flaws.

- Concentricity Testers: These tools ensure the inner hole is perfectly centered with the outer wall.

This level of inspection is not optional. It is integrated into every step of the process.

The High-Precision Manufacturing Process

Creating a ceramic sleeve is a multi-stage process. It is a blend of chemistry, physics, and engineering. A premier manufacturer has mastered every step.

Step 1: Formulation and Injection Molding

The process begins by mixing fine zirconia powder with a polymer binder. This mixture is heated to create a paste. The paste is then injected under high pressure into a precise steel mold. This forms the "green part." This part looks like a sleeve, but it is larger and brittle.

Step 2: Debinding

The green parts are placed in a special furnace. They are heated slowly in a controlled atmosphere. This process, called debinding, burns away the polymer binder. This must be done gradually. If heated too fast, the part will crack. What remains is a fragile, porous part made only of zirconia.

Step 3: Sintering

The porous parts are moved to a high-temperature furnace. They are heated to over 1,400°C. At this temperature, the zirconia particles fuse. The part shrinks significantly, by 20-25%. It becomes incredibly dense and hard. This step gives the sleeve its final material properties. Controlling the shrinkage is a key part of the manufacturer's expertise.

Step 4: Precision Finishing

After sintering, the sleeve is hard, but its dimensions are not yet perfect. It must be finished. This is where sub-micron precision is achieved.

- Centerless Grinding: The outer diameter is ground using diamond wheels.

- Lapping: The inner diameter is polished. This is a slow, careful process. It uses a fine diamond slurry to polish the inner wall. This creates the mirror-smooth finish and the exact final dimension.

Step 5: Slitting and Chamfering

For split sleeves, one final step is needed. A high-precision diamond saw cuts the narrow slit. The ends of the sleeve are also beveled. This is called chamfering. This small, angled edge helps guide the fiber ferrule into the sleeve. It prevents the sharp edge from chipping.

Quality Standards: ISO 9001 and Beyond

A trusted ceramic sleeves manufacturer in Germany proves its quality through certification. The most important standard is ISO 9001.

What is ISO 9001?

ISO 9001 is the global standard for a Quality Management System (QMS). It is not a product standard. It ensures the manufacturer:

- Documents all its processes.

- Has strong quality control at every step.

- Is committed to continuous improvement.

- Has full traceability for all materials and parts.

When you buy from an ISO 9001-certified manufacturer, you are buying a promise. It is a promise of consistency and reliability. You can learn more about this standard from the International Organization for Standardization.

Environmental and Regulatory Compliance

Top European manufacturers also adhere to other standards. These include RoHS (Restriction of Hazardous Substances) and REACH. These regulations control the use of certain chemicals. This ensures the products are safe for consumers and the environment.

Applications for German-Made Sleeves

The demand for these components comes from industries where failure is not an option.

Telecommunications and Data Centers

This is the largest market. Every fiber optic connection in a data center, every 5G tower, and every home internet connection relies on these sleeves. They are in the adapters in your wall plate. They are in the patch panels in the data center.

Medical Technology

Zirconia is biocompatible. It is non-toxic and is not rejected by the human body. This makes it ideal for medical devices. High-precision ceramic sleeves are used in:

- Surgical laser delivery systems.

- Endoscopes and diagnostic tools.

- Medical sensing equipment.

Aerospace and Defense

These industries demand extreme reliability in harsh environments. Sleeves must perform under high vibration, extreme temperatures, and mechanical stress. The robust nature of German-engineered zirconia sleeves makes them ideal for these "mil-spec" applications.

Distinguishing Zirconia Sleeves from Fiber Sleeves

It is important to understand a key difference. The precision components made by a ceramic sleeves manufacturer in Germany are alignment sleeves. They are hard, dense, structural parts made of zirconia.

There is another product with a similar name: ceramic fiber sleeves.

- Zirconia Alignment Sleeves: Hard, dense, polished. Used for micron-level alignment.

- Ceramic Fiber Sleeves: Soft, woven, flexible. Made from alumina-silica fibers. They are used for high-temperature insulation, like a protective wrap for a hot pipe.

A supplier of ceramic fiber sleeves Japan or ceramic fiber components Indonesia is in a completely different industry. They focus on thermal management, not precision alignment.

The Global Context: A Benchmark for Quality

The market for ceramic components is global. There are high-volume manufacturers in many regions. There are also high-quality producers of ceramic sleeves USA. Each market has its strengths.

The German manufacturing sector is known for its "Mittelstand." These are small- and medium-sized companies. They are often world leaders in a very specific, niche product. They compete by being the best, not the cheapest.

This is the environment of a top ceramic sleeves manufacturer in Germany. They are often leaders in material science. They may be developing new ceramic composites.

How to Choose a Manufacturer

When selecting a supplier for such a critical part, you must look beyond price.

- Ask for Material Datasheets: The manufacturer should provide a full technical datasheet for their Y-TZP material.

- Verify ISO 9001 Certification: Ask for a copy of their current certificate.

- Inquire About Tolerances: Ask for their standard manufacturing tolerances for ID, OD, and concentricity. A top-tier manufacturer will state these clearly.

- Request Samples: The best way to judge quality is to see it. Get samples and have them measured by an independent lab if possible.

- Discuss Technical Support: Does the manufacturer have engineers you can talk to? Can they help you with a custom design?

Conclusion: A Partnership in Precision

Choosing the best ceramic sleeves manufacturer in Germany is about finding a partner. You are not just buying a component. You are buying a guarantee of precision.

These components are the invisible foundation of our connected world. Their quality is measured in microns. Their impact is measured in gigabits. By selecting a manufacturer who embodies the principles of precision, quality, and reliability, you ensure your own products can perform at the highest level.

In This Article

- 1 What Are High-Precision Ceramic Sleeves?

- 2 The Hallmarks of German Precision Engineering

- 3 The High-Precision Manufacturing Process

- 4 Quality Standards: ISO 9001 and Beyond

- 5 Applications for German-Made Sleeves

- 6 Distinguishing Zirconia Sleeves from Fiber Sleeves

- 7 The Global Context: A Benchmark for Quality

- 8 How to Choose a Manufacturer

- 9 Conclusion: A Partnership in Precision

English

English 中文

中文