Industrial Ceramic Rods Supplier China

A premier Industrial Ceramic Rods Supplier China is a critical partner for global industries. These suppliers provide the high-performance components that function in extreme environments. Standard materials like metal and plastic fail in these conditions. Ceramic rods offer superior resistance to heat, wear, and corrosion. Suppliers in this market have scaled production. They meet the massive global demand for these advanced materials. They combine high-volume capacity with strict quality control.

This article explores the world of industrial ceramic rods. It details the materials, manufacturing processes, and key applications. It also covers the critical role of a top-tier supplier. These suppliers are the link between advanced manufacturing and the industries that rely on it.

What Are Industrial Ceramic Rods?

An industrial ceramic rod is a dense, cylindrical component. It is made from advanced, engineered ceramic materials. These materials are not the same as traditional pottery. They are highly purified. They are processed to achieve specific performance traits. These rods are used in thermal, mechanical, and electrical applications.

Defining the Industrial Component

An industrial ceramic rod is built for work, not for appearance. Its value is in its performance. It must provide a long, reliable service life. It is often a key part of a larger machine. Its failure can stop an entire production line. Therefore, its quality and consistency are paramount.

Why Ceramics are Superior to Metals and Plastics

Engineers choose ceramic rods to solve problems. Metals and plastics have clear limitations.

- Metals conduct electricity. They corrode when exposed to chemicals. They lose their strength and deform at high temperatures.

- Plastics have low melting points. They creep under load, meaning they deform over time. They degrade in UV light and swell with solvents.

Ceramic rods overcome all these issues. We are excellent electrical insulators. They are chemically inert. They maintain extreme hardness and strength at high temperatures.

The Role of a High-Volume Supplier

A high-volume supplier is essential to the global market. They provide the scale needed to make these components accessible. A supplier for ceramic rods china must manage several factors. They must balance production capacity with quality. We must manage a complex supply chain. They deliver millions of standard components. This allows industries to operate efficiently.

Understanding the "Industrial Grade" Specification

An "industrial grade" specification focuses on function. It prioritizes properties like thermal stability and wear resistance. It may allow for wider cosmetic tolerances than a medical-grade part. The dimensions, however, must be precise. The material properties must be consistent. A good supplier provides a clear technical data sheet for every industrial-grade rod. A ceramic rod can explain these grades in more detail.

Core Materials for Industrial Rods

The performance of a ceramic rod is defined by its material. A premier Industrial Ceramic Rods Supplier China will offer several material options. The two most common are alumina and zirconia.

Alumina (Aluminum Oxide): The Industry Workhorse

Alumina (Al2O3) is the most widely used technical ceramic. It is valued for its excellent balance of properties. It is also very cost-effective. Alumina is known for its high hardness, high compressive strength, and excellent electrical insulation. It is the default choice for many industrial uses.

Key Properties of Alumina Ceramic Rods

Alumina ceramic rods are chosen for their versatility. Their performance is often tied to their purity.

- 95% Alumina: This is a common grade. It has a good balance of properties. It is used for wear parts and supports.

- 99% Alumina: This grade offers better electrical insulation. It also has higher wear resistance.

- 99.5%+ Alumina: High-purity grades are used for more demanding applications. This includes semiconductor and medical equipment. They offer superior chemical resistance.

Alumina is thermally conductive. It can dissipate heat. This makes it useful in some electronic applications. It is stable in both oxidizing and reducing atmospheres.

Zirconia (Zirconium Oxide): The Toughness Specialist

Zirconia (ZrO2) is a premium ceramic material. It is known for one property above all: toughness. While most ceramics are hard but brittle, zirconia is different. It is stabilized with yttria (Y-TZP). This gives it a unique ability to resist cracking.

Key Properties of Zirconia Ceramic Rods

Zirconia ceramic rods are used when alumina is not tough enough.

- High Fracture Toughness: It resists impact and mechanical stress. This is due to a process called "transformation toughening."

- Low Thermal Conductivity: Unlike alumina, zirconia is a thermal insulator. It blocks heat very effectively.

- Similar Thermal Expansion to Steel: This allows ceramic-to-metal assemblies to be joined.

- High Flexural Strength: It can withstand bending forces.

Zirconia rods are ideal for mechanical components. This includes shafts, plungers, and fixtures.

Comparing Alumina and Zirconia for Industrial Use

Choosing the right material is a key engineering decision.

- Use Alumina for: High temperatures, electrical insulation, and wear resistance at a good cost.

- Use Zirconia for: High mechanical stress, impact resistance, and low-friction applications.

Other Advanced Materials (Silicon Carbide, Silicon Nitride)

Suppliers may also offer more specialized materials.

- Silicon Carbide (SiC): Known for its extreme hardness. It has excellent thermal conductivity. It is used for high-temperature heating elements.

- Silicon Nitride (Si3N4): Has the best thermal shock resistance. It can be heated and cooled rapidly without cracking. It is used in automotive engines.

The Manufacturing Process for Ceramic Rods

Ceramic rods are not cast or forged like metals. They are created from fine powders. This is a multi-stage, high-control process.

From Raw Powder to Formulated Slurry

The process begins with ultra-pure ceramic powders. These powders are often in the sub-micron range. They are mixed with binders, plasticizers, and other agents. This creates a consistent, moldable slurry or paste. The quality of this initial mix is critical. Any impurity can cause a failure later.

Forming Method 1: Extrusion for Standard Rods

This is the most common and cost-effective method for rods. The ceramic paste is forced through a die. A die is a steel tool with a circular opening. This process is like pushing pasta through a machine. It creates a long, continuous "green" rod. This green rod is then cut to the desired length.

Forming Method 2: Isostatic Pressing for Density

For larger or higher-specification rods, pressing is used. The ceramic powder is placed in a flexible mold. The mold is then subjected to high pressure from all sides. This can be cold (CIP) or hot (HIP). This process, called isostatic pressing, creates a very uniform, dense green part.

The Critical Debinding and Sintering Stages

The "green" part is fragile. It is a mix of ceramic powder and binder. It must be fired to become a hard ceramic. This is a two-step thermal process.

Sintering: Creating the Dense, Hard Part

The part is heated in a high-temperature furnace. This is the sintering stage.

- Binder Burnout (Debinding): The rod is heated slowly, often around 600°C. This process burns away the polymer binder.

- Sintering: The temperature is raised much higher. This is often over 1600°C for alumina. At this heat, the ceramic particles fuse. The part shrinks by 15-25%. It becomes incredibly hard and dense.

Secondary Machining: Precision Grinding

After sintering, the rod is "as-fired." Its dimensions are not yet perfect. For high-precision applications, it must be finished. The rod is now extremely hard. It can only be machined with diamond tools. This is called "hard-grinding."

Lapping and Polishing for Smooth Finishes

Centerless grinding is the most common finishing step. The rod is spun between diamond-coated wheels. This grinds the outer diameter to a precise, uniform size. It can achieve tolerances of just a few microns. For an even smoother finish, the rod can be lapped. This is essential for sealing applications.

Key Properties and Specifications

Engineers select ceramic rods based on specific performance data. A good Industrial Ceramic Rods Supplier China will provide a full technical data sheet.

Mechanical Strength: Compressive and Flexural

Ceramics are exceptionally strong in compression. They are less strong in tension. Flexural strength is a key metric. It measures a rod's ability to resist bending. High strength ceramic rods are those made from advanced materials like zirconia.

Thermal Stability and Maximum Use Temperature

This is a primary advantage. Alumina rods can be used continuously at 1500°C or more. Metal rods would melt or deform. This makes them ideal for furnace parts.

Electrical Insulation (Dielectric Strength)

Technical ceramics are excellent electrical insulators. They have a high dielectric strength. This means they can withstand a high voltage before breaking down. This makes them ideal for power grid components.

Chemical and Corrosion Resistance

Ceramic rods are chemically inert. They do not react with most acids, alkalis, or chemicals. This is a key advantage over stainless steel. They are used in chemical pumps and processing.

Wear and Abrasion Resistance

Alumina and zirconia are extremely hard. They are much harder than tool steel. In an abrasive slurry or a high-wear guide, a ceramic rod will last many times longer than a metal one.

Critical Industrial Applications

The unique combination of properties makes ceramic rods useful in almost every industry.

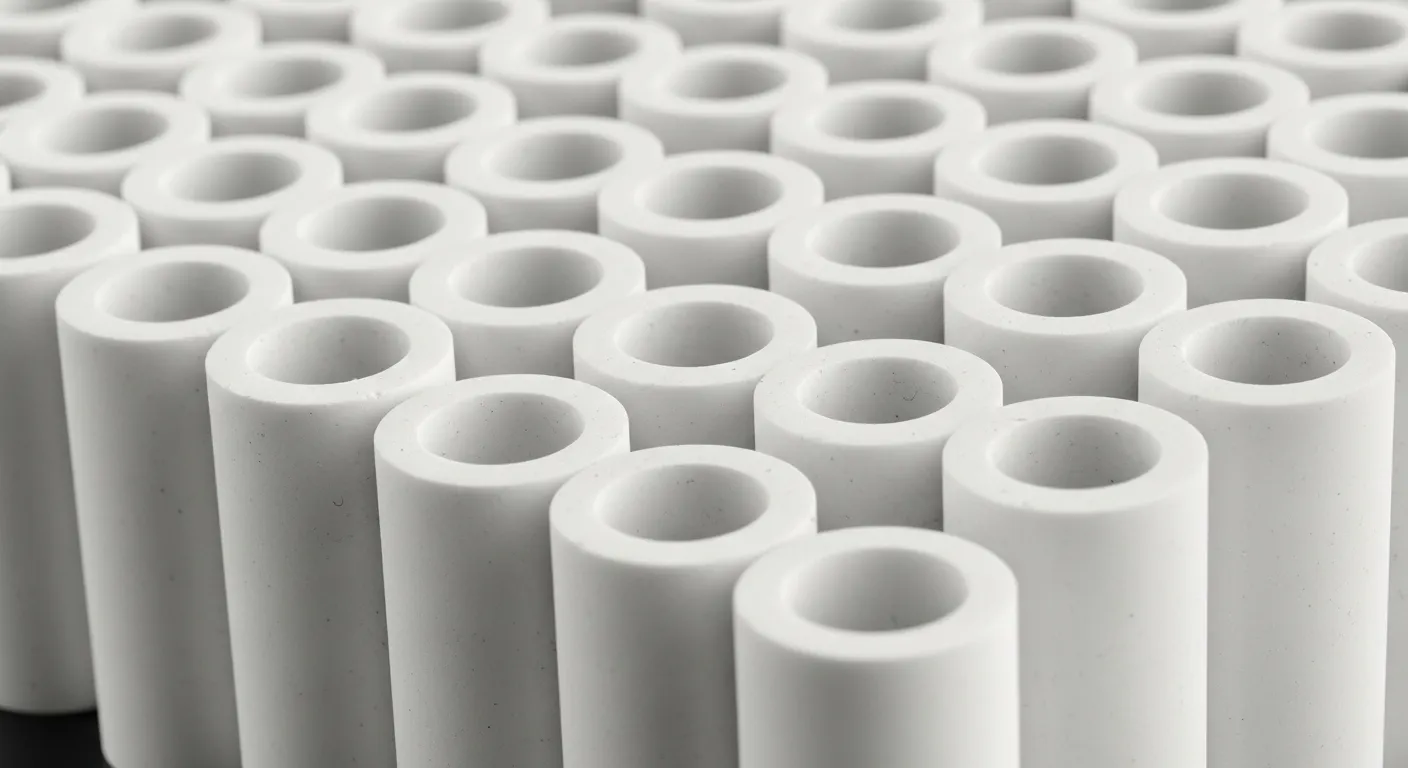

Furnace and Kiln Components

This is a major application for alumina rods.

- Supports: Ceramic rods are used as supports for products inside a furnace.

- Rollers: Long ceramic tubes (hollow rods) are used. They transport materials like glass through a hot furnace.

- Heating Element Supports: Rods hold and insulate electric heating elements.

Chemical Processing

- Pump Shafts: In chemical pumps, a zirconia rod will outlast a metal shaft. It will not corrode.

- Valve Components: Ceramic balls and seats are used in corrosive-fluid valves.

- Stirrers: A ceramic rod can stir a hot, corrosive chemical solution.

Electrical Engineering

- High-Voltage Insulators: Alumina rods are used as standoff insulators. They support high-voltage wires. They prevent electricity from arcing to the ground.

- Capacitor Cores: Ceramic rods are used as the core for certain electronic components.

Manufacturing and Assembly

- Guide Rods and Pins: Ceramic rods are used as guides and locating pins in assembly jigs. Their wear resistance ensures a long life.

- Nozzles: Custom-machined rods are used as nozzles for dispensing or sandblasting.

- Shafts and Axles: In high-wear or non-conductive machinery, ceramic rods are used.

Medical and Laboratory Equipment

- Biocompatibility: Zirconia is biocompatible. It is not rejected by the human body. It is used for medical implants.

- Analysis Tools: Rods are used in thermal analysis equipment.

Advanced Optical and Sensor Applications

The field of ceramics is always advancing. Some materials are even processed to be clear. This creates advanced optical uses for transparent ceramics. These are used in lasers and high-tech sensors.

The Role of an Industrial Ceramic Rods Supplier China

Sourcing from a large manufacturing hub offers clear advantages. A top-tier Industrial Ceramic Rods Supplier China is a key part of this ecosystem.

Advantages of High-Volume Manufacturing

The primary advantage is scale. Manufacturers in this region have optimized their processes. They can produce millions of high-quality, standard-sized rods. This scale reduces cost. It makes advanced materials accessible to more industries.

Managing a Global Supply Chain

These suppliers are experts in logistics. They ship components all over the world. They understand international freight. We manage customs and compliance. This makes the sourcing process smooth for the buyer.

The Importance of Scale and Efficiency

Efficiency comes from this scale. Automated processes for extrusion, sintering, and grinding are used. This automation reduces errors. It also increases throughput. This lowers the cost per part.

Quality Assurance in Mass Production

A common concern with high-volume production is quality. A premier supplier manages this. They do this through rigorous quality control. We use statistical process control (SPC). They perform 100% inspection on critical dimensions.

A Hub for Global Sourcing

This market serves as a primary source for the entire globe. Many suppliers in other regions source their "blanks" or standard rods from these high-volume hubs.

Quality Assurance and Sourcing Standards

When selecting a supplier, quality assurance is the most important factor.

The Importance of ISO 9001 Certification

This is the first and most basic check. An ISO 9001:2015 certification proves the supplier has a documented, audited Quality Management System. Do not work with a supplier who does not have this.

Verifying Material Purity and Composition

The supplier must provide a Technical Data Sheet (TDS). This document lists the material properties. It should state the purity (e.g., 99.5% Alumina). A buyer should be skeptical of any supplier who cannot provide this.

Dimensional Accuracy and Tolerance Control

A good supplier will clearly state their standard tolerances. For "as-fired" parts, this might be ±1%. For ground parts, this will be much tighter, often ±0.05 mm or better.

How to Evaluate a Supplier

A buyer should ask several key questions.

- "Can you provide a full material data sheet?"

- "What are your standard dimensional tolerances for ground rods?"

- "Are you ISO 9001 certified?"

- "What is your inspection process for a 10,000-piece order?"

Understanding Technical Data Sheets (TDS)

The TDS is the proof of quality. It lists all the key properties. This includes density, flexural strength, dielectric strength, and maximum use temperature.

The Market for Custom Ceramic Components

Not all applications can use a standard rod. This is where custom ceramic rods become essential.

Beyond Standard Rods

A Custom Ceramic Rods Supplier China will also have a custom machining department. They can take a standard rod and add features to it. This capability is a sign of a full-service supplier.

Co-Engineering and Design for Manufacturability (DFM)

A good custom manufacturer is a partner. They will perform a Design for Manufacturability (DFM) review. They will look at a customer's drawing. We may suggest changes to improve the part or reduce its cost.

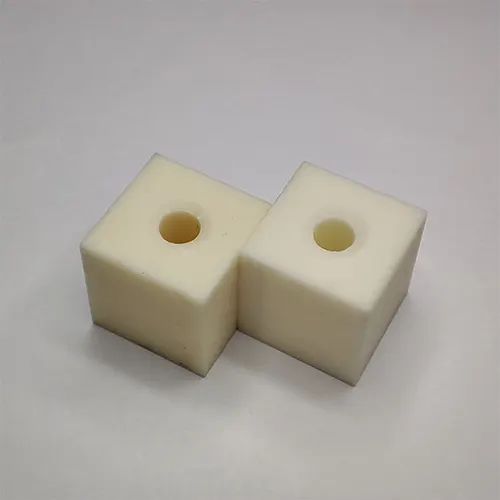

Custom Features: Threads, Grooves, and Holes

After sintering, the hard ceramic must be diamond-ground. A custom manufacturer can add complex features.

- Threads: Internal or external threads can be ground into the rod.

- Grooves: Grooves for o-rings or retaining clips.

- Holes: Cross-drilled holes for pins.

Sourcing Custom Parts from Specialized Hubs

The ability to make custom parts is a high-skill task. Sourcing a custom ceramic rods indonesia supplier, for example, is key. It supports that region's advanced manufacturing. A global supplier often has divisions that specialize in this.

Conclusion

A premier Industrial Ceramic Rods Supplier China is a vital global partner. They are not just a vendor. They are a high-volume manufacturing expert. We have mastered the complex science of technical ceramics. They produce the components that allow other industries to run hotter, faster, and more efficiently. We are the foundation of a reliable, cost-effective, and high-performance supply chain.

In This Article

- 1 What Are Industrial Ceramic Rods?

-

2

Core Materials for Industrial Rods

- 2.1 Alumina (Aluminum Oxide): The Industry Workhorse

- 2.2 Key Properties of Alumina Ceramic Rods

- 2.3 Zirconia (Zirconium Oxide): The Toughness Specialist

- 2.4 Key Properties of Zirconia Ceramic Rods

- 2.5 Comparing Alumina and Zirconia for Industrial Use

- 2.6 Other Advanced Materials (Silicon Carbide, Silicon Nitride)

-

3

The Manufacturing Process for Ceramic Rods

- 3.1 From Raw Powder to Formulated Slurry

- 3.2 Forming Method 1: Extrusion for Standard Rods

- 3.3 Forming Method 2: Isostatic Pressing for Density

- 3.4 The Critical Debinding and Sintering Stages

- 3.5 Sintering: Creating the Dense, Hard Part

- 3.6 Secondary Machining: Precision Grinding

- 3.7 Lapping and Polishing for Smooth Finishes

- 4 Key Properties and Specifications

- 5 Critical Industrial Applications

- 6 The Role of an Industrial Ceramic Rods Supplier China

- 7 Quality Assurance and Sourcing Standards

- 8 The Market for Custom Ceramic Components

- 9 Conclusion

English

English 中文

中文