LC Ceramic Sleeve Distributor India

A specialized LC ceramic sleeve distributor in India is a critical partner in building the nation's digital infrastructure. These distributors supply the single most important component for high-density fiber optics. The LC ceramic sleeve is a tiny, precision-engineered tube. It is the heart of every LC connector. Its perfection is what makes high-speed data centers and 5G networks possible. A premium distributor does not just sell a product. They provide a guarantee of quality, compliance, and availability.

The demand for data in this market is growing at an incredible pace. This requires network builders to install more fiber in smaller spaces. The LC connector, with its small 1.25 mm ferrule, is the industry's answer. A reliable distributor acts as the vital link. They connect the world's best manufacturers with local telecom operators, data center builders, and component assemblers. Their role is to ensure a stable supply of high-precision parts that meet all technical and regulatory standards.

What Is an LC Type Ceramic Sleeve?

An LC ceramic sleeve is a precision alignment component. The "LC" stands for "Lucent Connector." It is a small form factor (SFF) connector. The sleeve is the hollow cylinder inside the adapter. Its only job is to accept two fiber optic ferrules. It must hold them in perfect alignment. This allows light to pass from one fiber core to the other with almost zero loss.

The 1.25 mm Ferrule Standard

The LC sleeve is defined by its inner diameter. It is designed to accept a 1.25 mm ferrule. This is half the size of the older 2.5 mm standard used by SC and ST connectors. This smaller size is the LC's main advantage. It allows manufacturers to double the connection density on panels and equipment. An LC ceramic sleeve distributor in India provides the core component for this high-density standard.

Why Zirconia is the Only Material of Choice

These sleeves are not made of simple ceramic. They are made from an advanced material called Yttria-Stabilized Zirconia (Y-TZP). This material is chosen for a unique set of properties.

- Extreme Hardness: Zirconia is harder than steel. It does not wear out or deform after thousands of connections.

- High Fracture Toughness: This is its key trait. Unlike brittle ceramics, zirconia can absorb impact. This is essential for the split-sleeve design.

- Sub-Micron Precision: Zirconia can be machined to incredible tolerances. The inner diameter of a sleeve is often held to ±0.0005 mm.

- Thermal Stability: The material does not expand or contract with temperature. This is vital for data centers with hot and cold aisles.

- Smooth Surface: It can be polished to a mirror finish. This prevents it from scratching the fiber ferrule.

The Split Sleeve Design

Most LC ceramic sleeves are "split" sleeves. They have a single, narrow slit cut down the length. This is a critical design feature. It allows the hard zirconia to flex slightly. When a ferrule is inserted, the sleeve compresses. This creates a gentle, consistent grip. This grip holds the ferrule securely. It also ensures a perfect fit.

The Role of a Premium Distributor

A premium LC ceramic sleeve distributor in India is not just a box-moving reseller. They are a sophisticated supply chain and quality partner. Their job is complex. They bridge the gap between global manufacturers and local projects.

Managing a Complex Supply Chain

The world's best-in-class ceramic components are made in specialized factories. These factories are often located overseas. A local distributor handles the complex process of procurement. This includes managing import logistics, customs clearance, and currency fluctuations. They take on this burden. This allows their customers to receive parts as if they were sourced locally. This is a key advantage for projects that source from a ceramic sleeves supplier India.

Guaranteeing Quality and Compliance

This is the most important role of a distributor. They act as the first line of defense for quality. A premium distributor invests in their own metrology tools. They sample and test incoming batches. They check for dimensional accuracy, concentricity, and visual defects. We ensure that the millionth sleeve is identical in quality to the first.

Providing Local Inventory

A large-scale fiber rollout cannot wait 12 weeks for a shipment. A premium distributor maintains a large, local inventory. They have warehouses in key logistics hubs. This provides a buffer for the entire industry. Customers can get parts in days, not months. This "just-in-time" availability is essential for keeping projects on schedule.

Offering Technical Support

A premium distributor has engineers on staff. They understand the product. They can help a customer troubleshoot a problem. We can provide technical datasheets. They can advise on the correct sleeve for a specific application. This local, expert support is invaluable. It is a service that cannot be matched by an overseas manufacturer.

The Indian Regulatory Landscape: TEC Certification

This is the most critical factor for a distributor in this market. The government has a strict regulatory framework for telecom equipment. This is known as the MTCTE scheme.

What Is TEC and MTCTE?

TEC stands for the Telecommunication Engineering Centre. It is the technical body that sets standards for the Department of Telecommunications (DoT). MTCTE stands for Mandatory Testing and Certification of Telecom Equipment. This is the law. It states that any telecom equipment sold, imported, or used in the country must be certified by TEC.

How TEC Certification Affects LC Sleeves

A single, tiny ceramic sleeve does not get its own certificate. However, the components it is part of do require certification. The MTCTE scheme covers "Optical Fibre Equipment" and "GPON" systems. GPON systems are broken down into their components. This list includes "passive hardware" such as:

- Fiber optic patch cords

- Connectors

- Adapter panels

An LC adapter cannot be sold or used in a network without TEC certification. Since the LC sleeve is the key component inside the adapter, its quality is essential for passing TEC tests.

The Distributor's Responsibility

A premium LC ceramic sleeve distributor in India must guarantee TEC compliance. This is a non-negotiable part of their value. They ensure that the components they sell (like adapters) are from manufacturers who have completed the MTCTE process. This process is complex. It involves testing the products in a TEC-accredited lab.

Choosing a distributor who understands this process is vital. It protects the customer from legal risk. It also guarantees the product meets the national standard for quality and performance.

The Manufacturing Process: From Powder to Precision

Understanding how an LC sleeve is made reveals its complexity. A distributor must source from manufacturers who have mastered this process.

Step 1: Raw Material Formulation

It starts with an ultra-fine, high-purity powder. This is Yttria-Stabilized Zirconia (Y-TZP). This powder is mixed with a polymer binder. The binder helps the powder hold its shape.

Step 2: Precision Injection Molding

The powder-binder mixture is heated to a paste. It is then injected under high pressure into a steel mold. This mold is a precise negative of the sleeve. This creates the "green part." The green part is brittle. It is also about 20% larger than the final sleeve.

Step 3: Debinding and Sintering

The green parts are put into a special furnace.

- Debinding: The part is heated slowly. This burns away the polymer binder.

- Sintering: The temperature is raised to over 1,400°C. The zirconia particles fuse together. The part shrinks to its final, hard, dense state.

This thermal process is the "secret sauce" of manufacturing. It must be controlled perfectly.

Step 4: Precision Finishing (Lapping)

After sintering, the sleeve is hard. But its dimensions are not yet perfect. It must be finished.

- Grinding: The outer diameter (OD) is ground with diamond wheels.

- Lapping: The inner diameter (ID) is polished. This is a slow process. It uses a fine diamond slurry. It polishes the inner wall to a mirror finish. This step achieves the sub-micron tolerance.

Step 5: Final Inspection

Every single sleeve is inspected. An automated system uses air gauges to measure the ID. Lasers measure the OD. High-speed cameras check for cracks or chips. Any sleeve that is not perfect is discarded.

How to Select a Premium LC Distributor

When building a high-performance network, choosing the right partner is key. A cheap part from an unknown source is a massive risk. A premium distributor is an investment in reliability.

Key Criteria for Evaluation

When you evaluate an LC ceramic sleeve distributor in India, ask these questions:

- TEC Compliance: "Can you provide a Certificate of Conformity for TEC-certified adapters using these sleeves?" This is the most important question.

- Quality System: "Are you ISO 9001 certified?" This shows they have a documented quality management system.

- Local Inventory: "Where is your warehouse? What are your typical stock levels for 1.25 mm sleeves?"

- Technical Expertise: "Can I speak to your technical team about my application?"

- Traceability: "Can you provide full traceability for your components?" A good distributor can trace a batch of sleeves back to its origin.

Red Flags to Avoid

Be cautious of any supplier who:

- Does not know what TEC certification is.

- Cannot provide a material datasheet for their zirconia.

- Offers a price that is dramatically lower than others. This often means they are selling non-zirconia sleeves or parts that failed inspection.

- Has no local office or technical support.

Distinguishing Component Types

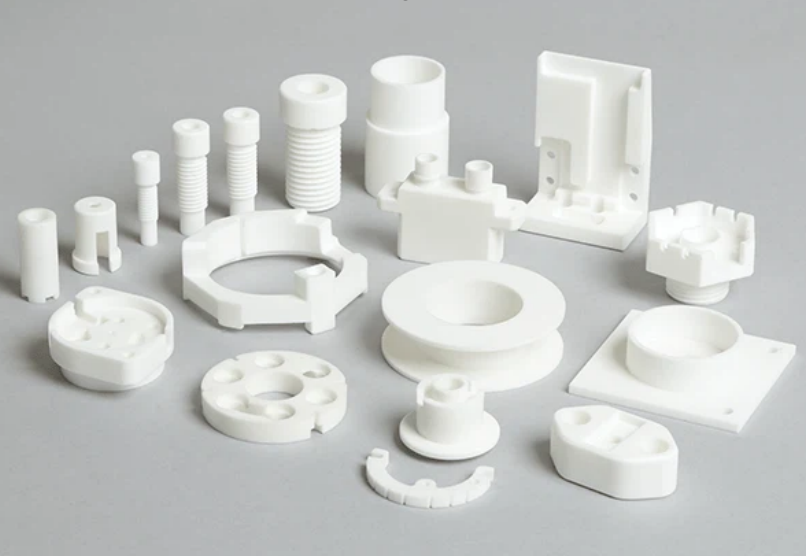

It is important to use the correct terminology. The components from a LC ceramic sleeve distributor in India are for precision fiber alignment. They are often confused with other industrial ceramic parts.

- Zirconia Alignment Sleeves: These are hard, dense, precision-polished components. They are for optical alignment. They are used in markets like ceramic sleeves USA and ceramic sleeves Europe.

- Ceramic Fiber Components: These are different. Products like ceramic fiber components Indonesia are soft, woven insulation materials. They are used for high-temperature heat shields in furnaces.

A premium distributor will only stock the high-precision Y-TZP zirconia sleeves. A general ceramic sleeves guide can explain this difference in more detail.

Conclusion: The Backbone of Digital India

The LC ceramic sleeve is a tiny, hidden component. But it is the backbone of the digital age. Every data center, every 5G tower, and every fiber-to-the-home connection depends on it. The performance of these networks is not limited by the fiber. It is limited by the quality of the connections.

A premium LC ceramic sleeve distributor in India is more than a supplier. They are a quality partner. They are an expert in global logistics and local regulations. By partnering with a premium distributor, network builders are ensuring their systems will be reliable, compliant, and fast.

English

English 中文

中文