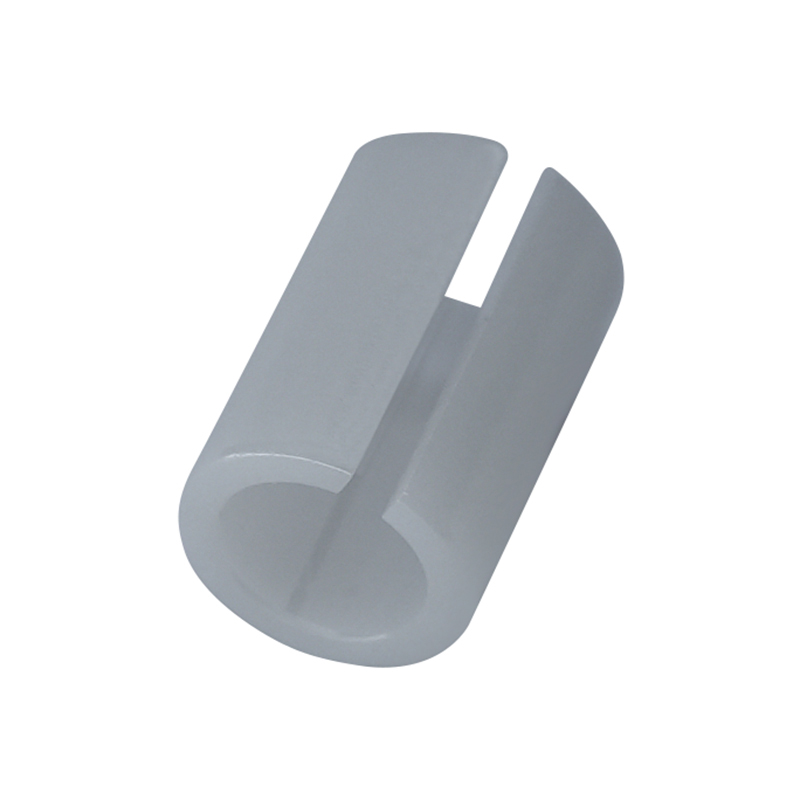

Zirconia Ceramic Spacers

Zirconia ceramic spacers are precision flat components used to provide accurate spacing, load distribution, or insulation between mating parts. With outstanding hardness, thermal stability, and corrosion resistance, they are widely used in electronics, optical systems, and mechanical assemblies.

- High-Purity Zirconia: Provides superior strength and crack resistance.

- Precision Engineered: Ensures tight tolerances (±0.05mm) for accurate spacing.

- Bulk Supply Available: Ideal for large-scale production needs.

- RoHS and REACH Compliant: Meets international environmental standards.

- Durable Design: Offers long-lasting stability and reliability.

Zirconia Ceramic Spacers

Zirconia ceramic spacers are specialized components made from zirconium dioxide (ZrO₂), a high-performance ceramic material known for its exceptional mechanical properties, thermal stability, and wear resistance. These spacers are used in various industrial, mechanical, and electrical applications where precision, durability, and high resistance to harsh environments are crucial. Zirconia ceramic spacers are often used to maintain proper alignment between components, absorb shock, and reduce wear in systems that experience high stress or operate at elevated temperatures.

Technical Specifications

| Parameter | Typical Range |

| Length Range | ≤300mm |

| Outer Diameter | ≤150mm |

| Surface Roughness | Ra0.02-Ra0.2 |

| Minimum Wall Thickness | 0.1mm |

| Roundness | 0.002mm |

| Concentricity | 0.002mm |

| Straightness | 0.004mm |

| Perpendicularity | 0.005mm |

Please refer to our Processing Capability Table for the full range of processing capability.

Advantages of Zirconia Ceramic Spacers

- Exceptional Mechanical Strength: Due to their high fracture toughness, zirconia spacers provide outstanding resistance to cracking and chipping.

- Superior Wear Resistance: As a result, they maintain dimensional integrity even in high-friction or load-bearing applications.

- Thermal Stability: Therefore, they perform reliably in high-temperature environments without deforming or degrading.

- Chemical Inertness: Consequently, they resist corrosion from acids, bases, and solvents, making them ideal for harsh environments.

- Precision Machining Capability: Thanks to advanced fabrication methods, they can be manufactured with tight tolerances and smooth finishes.

- Non-Magnetic and Electrically Insulating: As such, they are perfect for applications that require electrical isolation and magnetic neutrality.

Applications of Zirconia Ceramic Spacers

- Electronics and Semiconductors: Because of their insulating properties and precision, they are used to separate and align sensitive electronic components.

- Medical and Dental Devices: Due to their biocompatibility and high cleanliness, they are suitable for implantable devices and surgical tools.

- Aerospace and Automotive Engineering: Consequently, they serve as thermal and structural insulators in compact, high-performance assemblies.

- Industrial Machinery: In these settings, they function as durable gap fillers and alignment aids in rotating and sliding systems.

- Optical and Laser Systems: Thus, they help maintain critical distances and optical alignments without thermal expansion effects.

- Laboratory Equipment: Especially in chemically reactive or sterile environments, they are ideal for spacing components with high precision.

Enquire Now

- Welcome to contact us for more product information and quotes!

- Support customization according to drawings, quick response, short delivery guarantee!

- Consult Now

English

English 中文

中文