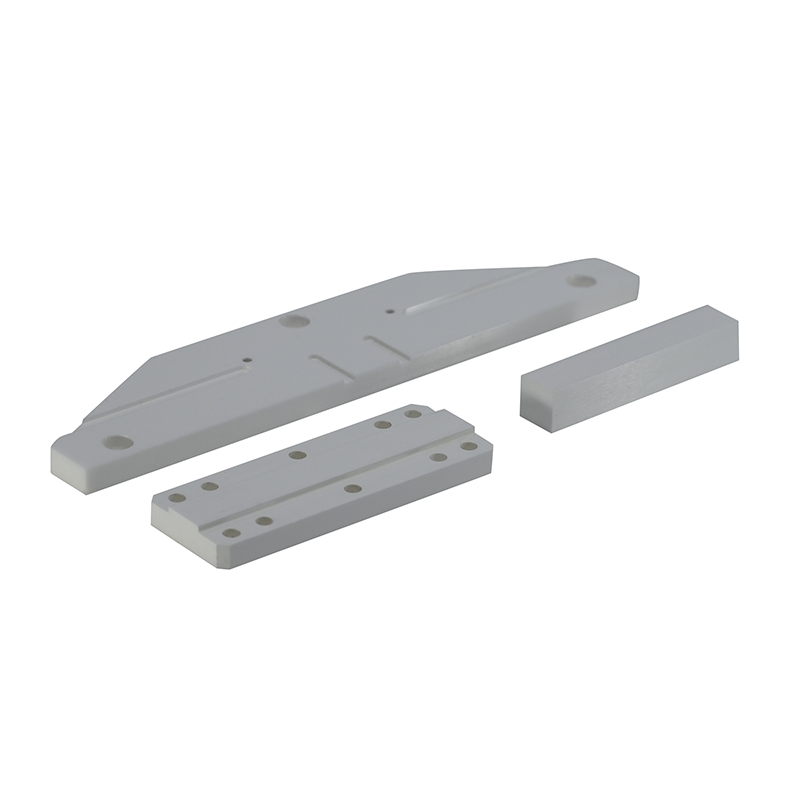

Metallized Ceramics

Metallized ceramics combine the mechanical strength and insulation properties of ceramics with the conductivity and bonding capabilities of metal layers. These components are widely used in vacuum electronics, medical devices, aerospace, and sensor systems. By applying metal films (typically Mo/Mn, W, or Ag/Pd) onto ceramic substrates such as alumina, they enable reliable ceramic-to-metal or ceramic-to-wire connections.

- Excellent ceramic-to-metal bonding

- Strong electrical insulation

- High thermal stability

- Corrosion and wear resistance

- Customizable metallization patterns

Metallized Ceramics

Metallized ceramics are ceramic materials that have been coated with a layer of metal to combine the beneficial properties of both ceramics and metals. This metallization process improves the ceramic's electrical, thermal, and mechanical properties, making metallized ceramics ideal for applications that require high performance in harsh conditions. The process involves applying a metal layer, typically through methods such as brazing, sputtering, or electroplating, to ceramic substrates, allowing for the creation of components that can handle both high thermal and electrical loads.

Technical Specifications

| Parameter | Typical Range |

| Length Range | ≤300mm |

| Outer Diameter | ≤150mm |

| Surface Roughness | Ra0.02-Ra0.2 |

| Minimum Wall Thickness | 0.1mm |

| Roundness | 0.002mm |

| Concentricity | 0.002mm |

| Straightness | 0.004mm |

| Perpendicularity | 0.005mm |

Please refer to our Processing Capability Table for the full range of processing capability.

Advantages of Metallized Ceramics

- High Mechanical Strength: Combines the durability of ceramics with the functional benefits of metallization for structural reliability.

- Excellent Hermetic Sealing: Enables strong, vacuum-tight seals between ceramic and metal components for use in critical environments.

- Electrical Conductivity at Interfaces: Allows for electrical connections and grounding where ceramic alone would be non-conductive.

- Thermal and Chemical Stability: Retains integrity in extreme temperatures and corrosive environments.

- Strong Ceramic-to-Metal Bonding: Metallization facilitates soldering, brazing, or welding to metal components without mechanical fasteners.

- Customizable Surface Properties: Metallization layers can be tailored for specific conductivity, adhesion, or sealing requirements.

Applications

- Vacuum and Pressure Sensors: Provides reliable sealing and electrical connections in high-vacuum or pressurized environments.

- Electronic Packages and Feedthroughs: Used in semiconductor, microwave, and RF systems for insulation and connectivity.

- Medical Implants and Devices: Applied in pacemakers and diagnostic equipment for hermetically sealed, biocompatible enclosures.

- Aerospace and Defense Systems: Supports high-reliability components that must withstand thermal cycling and vibration.

- Power Electronics: Ideal for substrates and housings in high-voltage and high-frequency switching devices.

- Laser and Photonic Equipment: Enables robust, stable integration of ceramic insulators with conductive pathways for optical alignment systems.

Enquire Now

- Welcome to contact us for more product information and quotes!

- Support customization according to drawings, quick response, short delivery guarantee!

- Consult Now

English

English 中文

中文