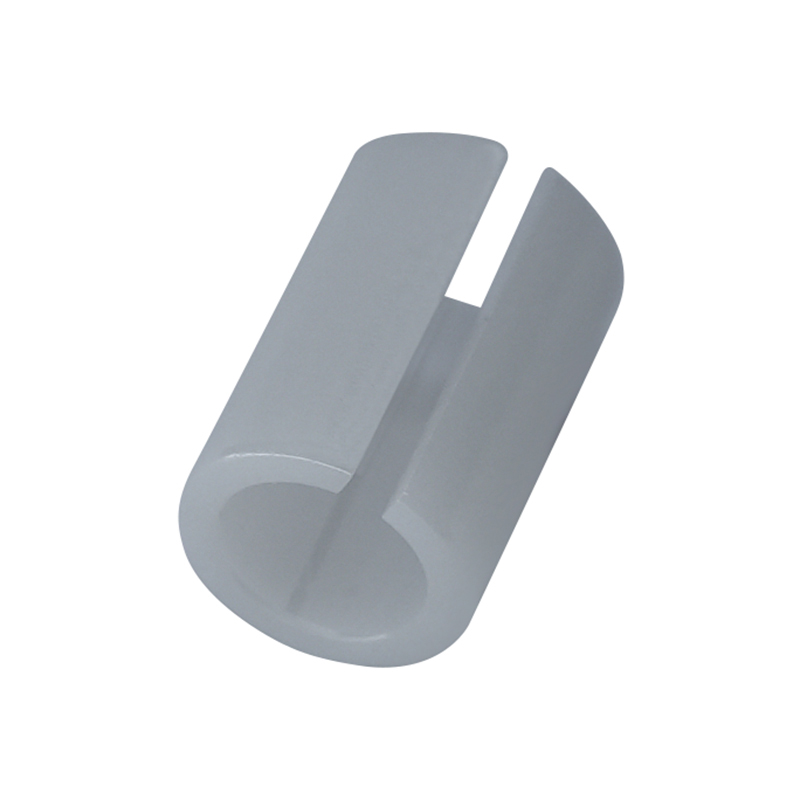

Black Zirconia Ceramic Parts

Black zirconia ceramic parts offer outstanding mechanical strength, fracture toughness, and aesthetic appearance. With excellent surface finish and structural integrity, these components are ideal for applications requiring both high performance and visual contrast. Common forms include tubes, plates, rings, and custom shapes—widely used in precision machinery, medical devices, electronics, and consumer products.

- High strength and fracture toughness

- Smooth surface with premium black appearance

- Excellent wear and corrosion resistance

- High precision and tight tolerances

- Custom production available

Black Zirconia Ceramic Parts

Black zirconia ceramic parts are made from zirconium dioxide (ZrO₂) that has been specially treated to develop a black color. Zirconia is a high-performance ceramic valued for its exceptional strength, toughness, wear resistance, and high-temperature stability. The black coloration is achieved through unique manufacturing processes or the addition of stabilizers or coloring agents, all without affecting the material’s core properties.

Technical Specifications

| Parameter | Typical Range |

| Length Range | ≤300mm |

| Outer Diameter | ≤150mm |

| Surface Roughness | Ra0.02-Ra0.2 |

| Minimum Wall Thickness | 0.1mm |

| Roundness | 0.002mm |

| Concentricity | 0.002mm |

| Straightness | 0.004mm |

| Perpendicularity | 0.005mm |

Please refer to our Processing Capability Table for the full range of processing capability.

Advantages of Black Zirconia Ceramic Parts

- Deliver Superior Mechanical Strength and Toughness: Black zirconia’s unique properties help these parts withstand heavy mechanical stress and resist cracking.

- Moreover, They Exhibit Excellent Wear and Abrasion Resistance: As a result, abrasive conditions do not degrade their surface integrity.

- In Addition, These Parts Offer Outstanding Thermal and Chemical Stability: Consequently, they reliably perform under extreme temperatures and corrosive environments.

- Besides Durability, They Combine Functional and Aesthetic Benefits: For example, their distinct black color reduces light reflection, enhancing optical applications.

- Furthermore, They Provide Electrical Insulation and Magnetic Neutrality: These features make them ideal for sensitive electronic and magnetically influenced systems.

- Thanks to Advanced Fabrication Techniques, Manufacturers Customize Them with Precision: This allows for complex geometries and tight tolerances.

Applications of Black Zirconia Ceramic Parts

- Medical and Dental Fields Use Them Widely: Surgeons and dentists rely on these parts for tools, implants, and components because of their biocompatibility and toughness.

- Industrial Machinery and Precision Equipment Incorporate Them: They serve as wear-resistant bearings, bushings, and guides in automated and heavy-duty machinery.

- Aerospace and Defense Engineers Choose Them: Their strength and thermal stability support critical components exposed to vibration and temperature extremes.

- Consumer Electronics and Luxury Goods Employ Them: Manufacturers select these parts for durable, attractive housings, watch bezels, and decorative elements.

- Automotive Applications Depend on Them: Designers integrate them into sensor mounts, valve guides, and engine parts that demand heat resistance and mechanical reliability.

- Optical and Laser Systems Benefit From Them: These parts reduce glare and increase durability in optical devices, improving performance.

Enquire Now

- Welcome to contact us for more product information and quotes!

- Support customization according to drawings, quick response, short delivery guarantee!

- Consult Now

English

English 中文

中文