Aluminum Oxide Ceramic Plate Demand Soars in High-Tech Manufacturing

Aluminum oxide ceramic plate is gaining attention in high-tech manufacturing. It offers exceptional hardness and thermal stability. Many factories now use it for precision parts. The material resists wear and extreme heat. Experts call it a breakthrough in durability. Its applications stretch from aerospace to electronics. Manufacturers praise its reliability and cost-effectiveness.

Why is this material suddenly in such high demand? What makes it stand out from traditional options? As global manufacturers face stricter quality demands and environmental challenges, the aluminum oxide ceramic plate offers solutions that others can’t match.

But that’s only part of the story. In the sections that follow, we’ll explore what’s really driving this surge—and what it means for the future of innovation.

The Silent Backbone Of High-Tech Growth

A New Star In Advanced Materials

The aluminum oxide ceramic plate is becoming a core material in modern manufacturing. It offers a rare mix of strength, stability, and precision. High-tech industries are now paying close attention to this powerful material.

Shifting Industry Demands

Today’s advanced machines need more than just metal. They require materials that can handle heat, pressure, and wear. Traditional metals often deform, corrode, or break under stress. The aluminum oxide ceramic plate solves many of these problems.

Setting The Stage For Growth

Why is demand for this material growing so fast? It’s not just strong—it’s smart. With high purity and excellent insulation, the aluminum oxide ceramic plate is used in aerospace, electronics, and cleanroom equipment. But there’s more to the story. What features make it a true game-changer?

What Is An Aluminum Oxide Ceramic Plate?

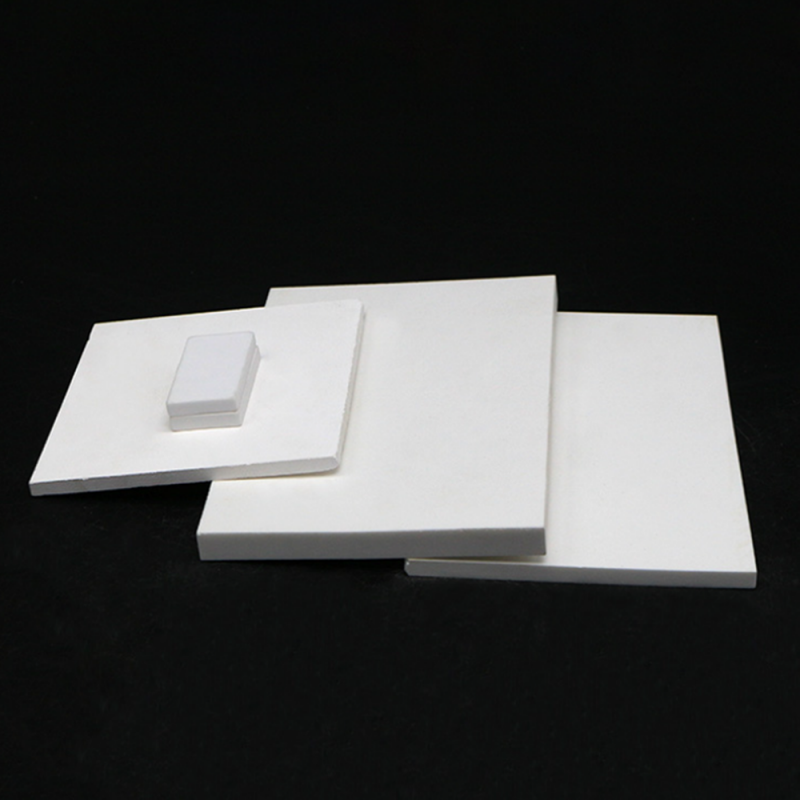

Material Composition

An aluminum oxide ceramic plate is made from high-purity alumina. This material is known for its excellent mechanical and chemical stability. It resists heat and corrosion, even in extreme environments.

Core Properties In One Package

This ceramic plate offers a rare combination: high hardness, strong electrical insulation, and thermal resistance. These features make it ideal for precision engineering and long-term performance.

Beyond The Surface

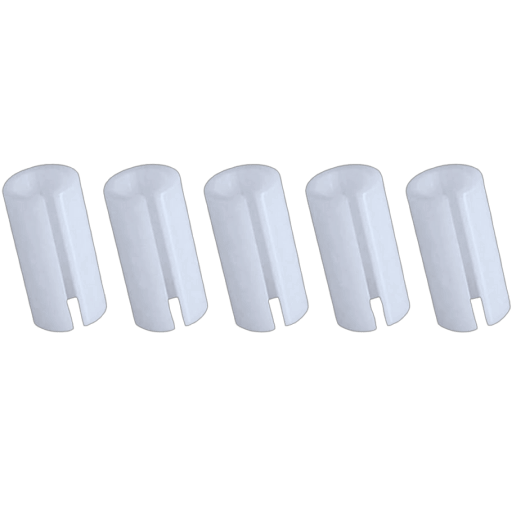

It’s not just the material that matters—it’s the precision. UPCERA’s aluminum oxide ceramic plate can be made with surface roughness as low as Ra0.1. Roundness and straightness can reach down to 0.002mm. These tight tolerances support high-performance devices where even the smallest error matters.

Key Performance Advantages In Industrial Use

Wear And Corrosion Resistance

In industrial settings, materials often face wear, friction, and corrosion. The aluminum oxide ceramic plate can operate under these conditions without losing its shape or strength. It lasts longer than metal in many harsh applications.

Electrical Insulation Where It Counts

This material is an excellent electrical insulator. That makes the aluminum oxide ceramic plate ideal for use in electronic systems and high-voltage equipment. It keeps components safe and prevents failures caused by electrical leaks or overheating.

Long Service Life Saves Cost

Thanks to its strength and resistance, this ceramic plate doesn’t wear out quickly. Fewer replacements mean lower maintenance costs. For industries that rely on stable, long-term performance, this is a big advantage.

Technical Specifications That Matter

Precision Engineering

The aluminum oxide ceramic plate is known for its tight tolerances. Straightness, roundness, and concentricity can reach 0.002mm. These precise values are essential for advanced machinery. They reduce vibration, misalignment, and friction.

Size And Surface Customization

Each aluminum oxide ceramic plate can be tailored by size. Lengths range up to 300mm. Outer diameter can be less than 150mm. Surface roughness can go as low as Ra0.1. This smooth surface helps reduce wear and ensures better contact with other components.

Design Freedom With Custom Geometry

The aluminum oxide ceramic plate supports complex shapes. We can make ultra-thin walls and exact angles. This flexibility allows it to be used in highly specialized machines. Every detail can be adjusted to fit the final application.

UPCERA’s Aluminum Oxide Ceramic Plates

High Purity, High Performance

At UPCERA, we use only high-purity alumina. This ensures that every aluminum oxide ceramic plate offers maximum strength and durability. We control every part of the production process to guarantee consistent quality.

Tailored To Fit Any Application

No two customers are the same. We offer custom shaping and finishing for every aluminum oxide ceramic plate. Whether for a lab instrument or an industrial robot, we can meet your design needs. From small runs to mass production, we deliver precision.

Certified And Trusted Worldwide

Quality matters to us. That’s why our aluminum oxide ceramic plates are ISO 9001, ISO 14001, and ISO 45001 certified. We also meet RoHS and REACH standards. Our global partners trust our products to perform in critical environments.

Real-World Applications: Where Innovation Meets Reality

Electronics And Semiconductors

The aluminum oxide ceramic plate is ideal for electronic systems. It is often used as a base or insulator. Its electrical resistance and dimensional stability make it perfect for cleanroom and high-voltage settings.

Medical And Lab Equipment

In labs and hospitals, cleanliness and accuracy are critical. Our ceramic plates are easy to sterilize and resistant to chemicals. They are used in surgical tools, diagnostic devices, and custom holders.

Aerospace And Robotics

Machines in aerospace and automation need materials that can handle stress and temperature. The aluminum oxide ceramic plate performs well in extreme heat and high-speed systems. It resists wear, stays strong, and maintains shape under pressure.

Power And Energy Systems

In energy storage and transmission, safety is key. Our ceramic plates are non-conductive and thermally stable. They are used in battery modules, reactor supports, and other critical components.

Why Choose UPCERA?

Global Reach, Local Focus

We serve clients in over 100 countries. From small custom orders to bulk production, we support global industries with speed and precision. Our aluminum oxide ceramic plates are found in devices worldwide.

Independent Innovation

In 2021, Shenzhen Upcera Innovative Materials Co., Ltd. became an independent operation. Since then, we’ve focused deeply on precision structural ceramics. We continue to invest in research, development, and smart manufacturing.

Commitment To Excellence

At UPCERA, we don’t just sell products—we provide solutions. Each aluminum oxide ceramic plate is made to strict standards. We listen to our customers and build long-term partnerships. Your success is our mission.

Final Words: Unlock Next-Level Manufacturing with UPCERA Ceramics

The aluminum oxide ceramic plate is reshaping high-tech manufacturing with its strength, precision, and versatility. From electronics to aerospace, it meets the demands of modern industry. At UPCERA, we deliver high-purity, custom-engineered ceramic solutions backed by global certifications and trusted expertise. Whether for small parts or complex systems, our products help you achieve long-lasting, reliable performance. Contact us today to explore how our ceramic technology can drive your next innovation forward.

English

English 中 文

中 文