Strong, sustainable: Aluminium oxide parts drive industrial innovation

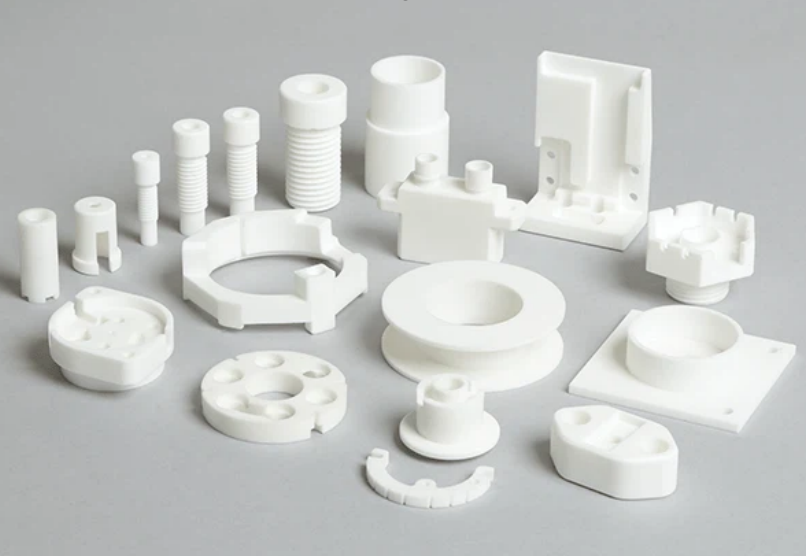

The era of precision manufacturing is accelerating, and alumina parts are at the core of this momentum. From semiconductor tools to aerospace components, these ceramic heroes deliver the strength, stability, and eco-efficiency today's industries demand - all while staying surprisingly cost-effective.

Why Alumina Parts Stand Out in Modern Engineering

Alumina (Al₂O₃) is more than a ceramic; it is a performance material. Formed through high-temperature sintering of high-purity aluminum oxide powder, alumina parts acquire a tightly packed lattice structure. The result is a component that is:

• Harder than most tool steels

• Chemically inert in corrosive media

• Thermally stable above 1 ,500 °C

Because alumina's grain structure resists deformation, designers can create thin-walled or complex profiles without sacrificing strength. That rigidity translates into precise tolerances that hold steady year after year, even under thermal shock, vibration, or aggressive chemicals.

• Dimensional Integrity You Can Count On

While metals may creep or oxidize, alumina's low coefficient of thermal expansion keeps dimensions predictable. In high-precision equipment - think robotic pick-and-place arms or micro-lithography stages - this stability ensures micron-level accuracy throughout the service life.

Key Advantages That Drive Industrial Adoption

Alumina parts are trusted across industries for one simple reason: they deliver consistent, high-performance results even in the toughest environments. Their unique material properties help businesses improve efficiency, reduce costs, and meet increasingly strict technical and environmental demands.

✅ Exceptional Hardness & Wear Resistance

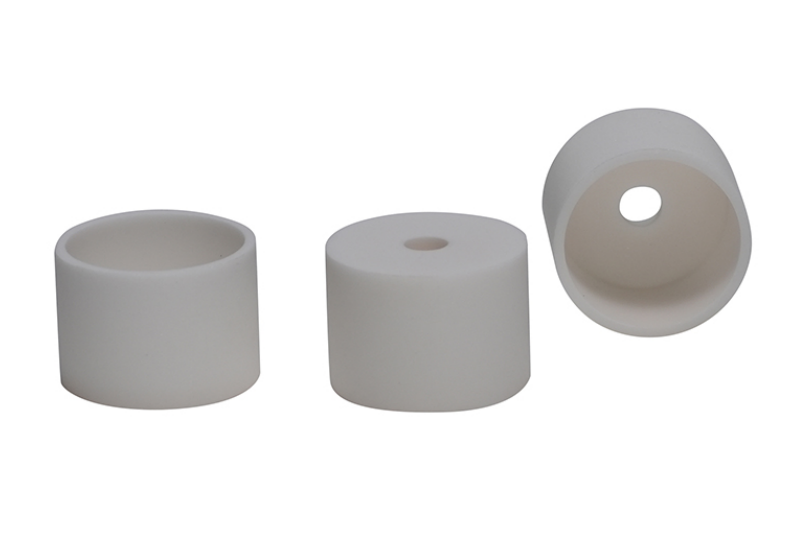

Alumina's dense, hard structure resists abrasion, friction, and particle impact. In high-wear settings like pumps, seals, or sliding components, this translates to dramatically longer service life.

✅ Thermal Stability at Extreme Temperatures

Withstanding continuous operation above 1,500 °C, alumina parts remain dimensionally stable in high-temperature processes such as metal casting, semiconductor fabrication, or jet propulsion.

✅ Corrosion & Chemical Resistance

Alumina's inert ceramic composition protects against acids, alkalis, and aggressive solvents - making it ideal for chemical processing, fluid handling, and cleanroom environments.

✅ Excellent Electrical Insulation

With volume resistivity up to 10¹⁴ Ω·cm, alumina is perfect for insulators and substrates in high-voltage or RF systems, where electrical isolation is non-negotiable.

✅ Tight Dimensional Precision

Advanced processing like isostatic pressing and precision grinding enables micron-level tolerances. This ensures compatibility with high-accuracy assemblies and automated systems.

✅ Long-Term Value & Cost Effectiveness

Fewer replacements and minimal maintenance make alumina a smart investment - reducing downtime and total ownership costs over time.

Combined, these advantages allow alumina parts to meet the evolving technical, regulatory, and sustainability needs of today's industrial world - without compromise.

Diverse Applications Across High-Tech Sectors

Alumina's versatility opens doors in industries that need performance without compromise.

• Semiconductors & Electronics

Wafer chucks, CMP rings, and plasma chamber liners all rely on alumina parts for plasma resistance and low particle generation. Their electrical insulation prevents stray currents that could destroy sensitive chips.

• Medical & Dental Devices

Bio-inert, sterilizable, and nonmagnetic, alumina components appear in surgical drills, implant abutments, and analyzer nozzles. Their smooth surface reduces bacterial adhesion while standing up to autoclave cycles.

• Automotive & Aerospace

Turbocharger rotors, fuel-pump plungers, and wear pads endure high RPM, temperature swings, and corrosive fuels. Alumina maintains its mechanical integrity where metals soften or polymers char.

• Industrial Machinery & Automation

From textile looms to food-processing lines, bushings and guide rails made of alumina minimize downtime. Their low friction coefficient keeps energy use low, contributing to greener factory operations.

Guidelines for Selecting Alumina Parts

When choosing alumina over metals or polymers, keep these design tips in mind:

✅ Match Grade to Stress - Fine-grain 99.9 % alumina suits ultra-high wear; 96 % grades balance cost and performance for moderate loads.

✅ Mind the Geometry - Sharp inside corners concentrate stress. Specify radii ≥ 0.5 mm to extend life.

✅ Allow Proper Clearance - Unlike ductile metals, ceramics cannot "give.” Provide adequate assembly tolerances and use compliant gaskets where necessary.

✅ Plan for Mounting - Threaded inserts or metal sleeves can distribute clamping forces and avoid point loading.

✅ Leverage Co-Design - Early collaboration with UPCERA's applications team lets you capture cost savings through optimized shapes and batch sizes.

By following these guidelines, engineers can unlock the full spectrum of alumina's capabilities while keeping production timelines predictable.

Why Choose UPCERA

At UPCERA, we take pride in being a globally recognized manufacturer of alumina parts and advanced ceramic solutions. With deep roots in material science and engineering, we combine academic excellence with industrial precision to deliver exceptional performance across industries.

• Our Strength

We offer more than just standard components. Our team works closely with you to design and manufacture alumina parts that meet tight tolerances, complex geometries, and specialized surface treatments. Every solution is tailored to your application, ensuring maximum performance and efficiency.

• What Sets Us Apart

✅ Outstanding R&D Capabilities

Our R&D team originated from the prestigious Tsinghua University, bringing years of experience in ceramic materials and continuous innovation. We have independently developed over ten categories of advanced ceramics, covering thousands of product variations with strong intellectual property protection.

✅ Deep Technical Collaboration

Through strategic cooperation with Sinocera, we enhance our control over raw materials and fundamental research. This partnership allows us to deliver ceramics with superior reliability, consistency, and cutting-edge properties.

✅ End-to-End Quality and Efficiency

From ISO-certified production lines to agile prototyping and fast lead times, we maintain strict quality systems (ISO 9001, 14001, 45001, REACH, RoHS). Our global delivery network and responsive customer service ensure a seamless experience from concept to delivery.

Whether you're developing the next generation of electronics or upgrading your manufacturing process, UPCERA is your trusted partner in ceramic engineering - driven by research, powered by precision, and committed to your success.

Looking Ahead

As industries continue to evolve, alumina parts will play a greater role in enabling smart manufacturing, clean energy, and medical technology. Their strength, resilience, and adaptability make them one of the most forward-looking materials in modern engineering.

Emerging opportunities for alumina parts include:

• Green hydrogen and battery technologies

• Advanced robotics and AI-driven manufacturing

• High-frequency and 5G telecommunications hardware

By choosing the right materials today, companies can future-proof their operations and remain competitive tomorrow.

Closing Thoughts

Alumina parts deliver a rare balance of strength, precision, and long-term reliability. Whether used in advanced manufacturing, electronics, aerospace, or automation, these components consistently enhance performance while supporting sustainable operations. At UPCERA, we're dedicated to helping you unlock the full potential of alumina in even the toughest applications. With our expertise, materials, and precision manufacturing, we provide more than just parts - we deliver solutions. Looking to elevate your product with stronger, sleeker, and more sustainable components? Get in touch with UPCERA today. Let's engineer a better future - together.

English

English 中文

中文