The role of fiber optic ceramic casing in telecommunications

The digital age depends on seamless, high-speed data transmission. At the heart of this network lies a small but vital component: the fiber optic ceramic sleeve. As UPCERA, we’ve spent two decades perfecting these precision parts. In this article, we’ll explore how fiber optic ceramic sleeves power modern telecom, boost reliability, and pave the way for future innovations.

Understanding Fiber Optic Ceramic Sleeves in Telecom

A fiber optic ceramic sleeve is a tiny tube that aligns two optical fibers within a connector. Though small, it has a huge impact on signal quality. When fibers mate, the sleeve ensures their cores line up precisely. This alignment minimizes signal loss, reduces return loss, and sustains transmission speeds, even across long distances.

In telecom networks – whether 5G base stations, metro rings, or long-haul links – reliable connections are nonnegotiable. A single misalignment can cause data dropouts or increased bit-error rates. Ceramic sleeves, made from zirconia, provide:

✓ Exceptional concentricity for core-to-core alignment

✓ High wear resistance to endure thousands of mating cycles

✓ Thermal stability to survive temperature swings in outdoor cabinets

By choosing the right fiber optic ceramic sleeve, operators safeguard network uptime. UPCERA’s sleeves deliver the precision and durability that modern telecom demands.

20+ Years of Expertise: UPCERA‘s Legacy

We at UPCERA know ceramic manufacturing inside out. For over 20 years, we’ve refined our processes to lead both standard and non-standard sleeve production. Our journey includes:

✓ Factory-direct supply with consistent quality control

✓ Advanced grinding and polishing techniques for sub-micron tolerances

✓ Rigorous testing under real-world temperature and humidity cycles

From our first SC-type sleeves to today’s custom split and solid designs, our mission remains the same: deliver reliable alignment components that exceed industry standards. This long-term commitment has earned UPCERA the trust of telecom giants, data center operators, and laser-equipment manufacturers worldwide.

Types of Ceramic Sleeves and Their Applications

• SC-Type Ceramic Sleeve

SC connectors are ubiquitous in telecom, FTTH, and CATV deployments. The SC-type ceramic sleeve by UPCERA offers:

✓ Low insertion and return loss (<0.2 dB typical)

✓ High mechanical strength to resist shock and vibration

✓ Custom lengths and diameters on request

Its robust zirconia construction ensures consistent performance, even in outdoor splice closures or high-density patch panels.

• LC-Type Ceramic Sleeve

As networks densify, LC connectors dominate data centers and high-speed links. Our LC-type sleeve features:

✓ Miniature format (Ø1.62 mm) for space-saving duplex arrays

✓ Superior alignment accuracy (≤0.02 µm concentricity)

✓ Repeatable mating cycles (>5000 cycles without degradation)

This sleeve supports both single-mode and multimode fibers, making it ideal for 400 G and beyond.

Why Precision Matters

Telecom operators demand parts that never fail. Here’s why a high-precision fiber optic ceramic sleeve makes a difference:

✓ Signal Integrity

Precise fiber alignment keeps insertion loss low. This ensures clean eye diagrams and high signal-to-noise ratios for error-free data.

✓ Long-Term Reliability

Zirconia’s hardness resists wear from repeated plug-unplug cycles. Networks remain stable over years of maintenance.

✓ Environmental Resilience

Ceramic sleeves tolerate humidity, UV exposure, and temperature swings from –40 °C to +85 °C. Outdoor enclosures stay sealed, and performance stays consistent.

✓ Electrical Isolation

Non-conductive ceramics prevent stray currents. This protects sensitive electronics in hybrid fiber-copper installations.

✓ Customizability

Need split sleeves for self-centering adapters? Or solid sleeves with special flanges? Custom production adapts to any telecom design.

By prioritizing these advantages, UPCERA helps network designers minimize downtime and reduce total cost of ownership.

Custom Solutions: Split and Solid Ceramic Sleeves

Telecom isn’t one-size-fits-all. Sometimes standard sleeves don’t fit special connectors, sensors, or laser modules. That’s when our custom sleeves shine.

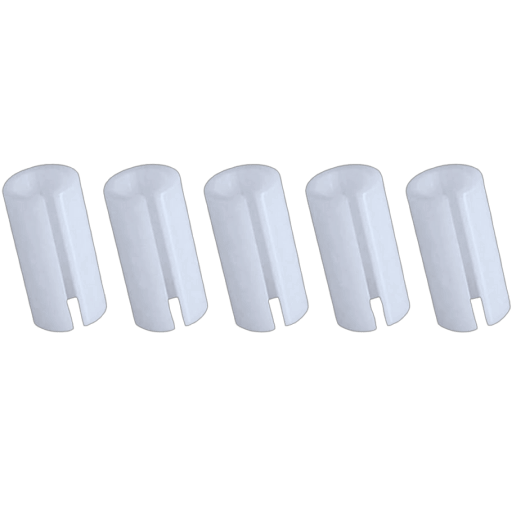

• Custom Split Ceramic Sleeve

✓ Self-centering design for easy installer use

✓ Adjustable ferrule grip for non-standard diameters

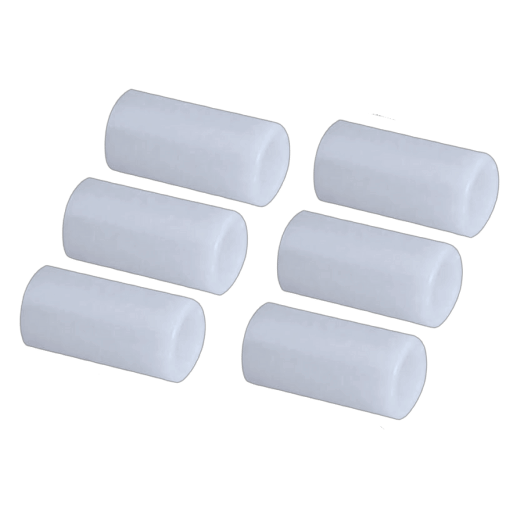

• Custom Solid Ceramic Sleeve

✓ Seamless tube ideal for sealed, high-pressure environments

✓ Precise bore control (±1 µm) for tight tolerance systems

These bespoke components support niche applications like fiber sensors, military radios, and lab instrumentation. UPCERA’s engineers work closely with clients to define dimensions, materials, and tolerances. The result: a tailor-made fiber optic ceramic sleeve that fits perfectly and performs flawlessly.

Future Trends and UPCERA‘s Roadmap in Telecom Connectivity

The telecom landscape is evolving fast. From 5G fronthaul to 800 G backbone upgrades, fiber counts and data rates keep rising. Here’s how UPCERA is preparing:

• Ultra-Low Loss Sleeves: Research into advanced ceramic materials aims to push insertion loss below 0.1 dB. This opens doors for longer single-span links.

• Smart Quality Control: Integrating AI-driven inspection systems to detect sub-micron defects. Every fiber optic ceramic sleeve undergoes real-time scanning during production.

• Green Manufacturing: Reducing waste in ceramic powder processing and reusing water in polishing stages. Sustainable practices without compromising quality.

Closing Words

As 5G, AI, and cloud computing evolve, so do the requirements for precise optical connectivity. The fiber optic ceramic sleeve is becoming more critical than ever – enabling faster speeds, more reliable transmission, and denser network architectures. At UPCERA, we’re proud to support this evolution. Our continuous investment in precision manufacturing ensures that your fiber optic systems run smoother, longer, and smarter.

Whether you’re designing for telecom, upgrading your data center, or prototyping a next-gen optical module – we have the fiber optic ceramic sleeve solution tailored to your needs. Want to explore more or request a sample? Contact UPCERA today and let’s build the future of fiber optics together.

- PREV: Why Industrial Ceramic Components Are Gaining Ground in Engineering

- NEXT: Null

English

English 中 文

中 文