How to Pick the Right Machined Ceramic Components

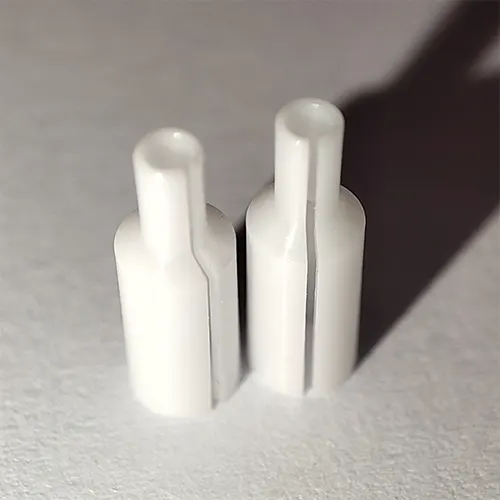

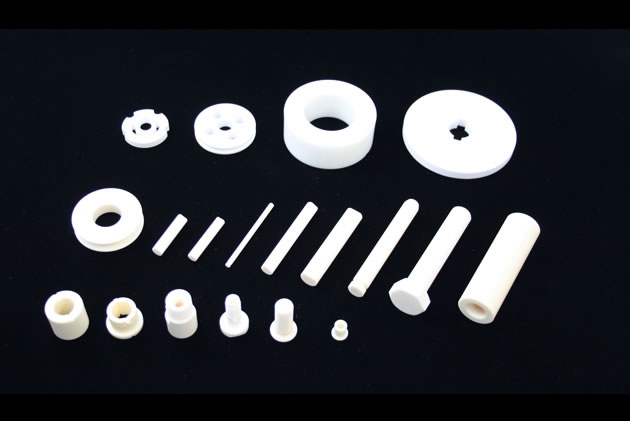

Machined Ceramic Components power the quiet reliability behind precision tools, automation systems, and high-duty equipment. At UPCERA, we manufacture, machine, and validate these parts so your projects run accurately, day after day. This guide explains how to choose the right solution, why Alumina Mechanical Parts are often the smart choice, and how our team supports you from concept to delivery.

1) How UPCERA Helps You Choose Machined Ceramic Components

Selecting Machined Ceramic Components starts with your operating realities. We look at load, motion, temperature, media, and the tolerances your assembly needs. Our engineers translate these conditions into a clear design and machining plan. The goal is simple: stable performance with predictable costs.

• Pain points we solve in real projects

✅ Premature wear in high-cycle mechanisms that shortens maintenance intervals

✅ Tight tolerances that drift after thermal shocks or long runs

✅ Exposure to corrosive media that attacks metals and polymers

✅ Surface finishes that create friction, particle generation, or seal failure

✅ Dimensional consistency across batches for automated assembly

• Practical selection factors for Machined Ceramic Components

✅ Fit and tolerances: Confirm roundness, concentricity, and straightness align with your mating parts

✅ Surface finish: Match Ra to motion and sealing needs to control friction and wear

✅ Thermal profile: Consider start-up, steady-state, and cycling temperatures

✅ Chemical exposure: Validate resistance to acids, alkalis, or process gases

✅ Geometry limits: Check length, diameter, and minimum wall thickness against feasible ranges

When you share your drawings and operating conditions, UPCERA proposes a manufacturable geometry, chooses the right alumina grade, and defines inspection points. This removes guesswork and reduces iteration time - especially for precision alumina ceramic machining services.

2) Why Alumina Mechanical Parts Are a Smart Choice

Alumina (Al₂O₃) offers a strong balance of hardness, wear resistance, and stability at elevated temperatures. That is why Alumina Mechanical Parts are widely used in machinery, automation, and precision equipment across automotive, aerospace, electronics, and manufacturing. For many teams, alumina delivers durable performance without complex maintenance plans.

These figures support tight assemblies and smooth motion. They also help you reduce variation and control stack-up in precision builds.

• Core Advantages of Alumina Mechanical Parts

✅ High wear resistance and long service life - ideal for continuous motion and abrasive contact

✅ Excellent mechanical strength and rigidity - parts stay true under load

✅ Dimensional precision and tight tolerances - consistent fit and predictable performance

✅ Corrosion and chemical resistance - stable in acids, alkalis, and aggressive media

✅ Thermal stability for high-temperature operations - reliable under thermal stress

✅ Superior electrical insulation - suitable where electrical isolation is required

✅ Cost-effective longevity - durability reduces replacements and downtime

If your application is sensitive to contamination or particulate, the right surface finish and geometry can further protect seals, bearings, and wafers. Our machining and inspection workflows keep those parameters controlled from lot to lot.

3) From Application Fit to Delivery: Your Path with UPCERA

The final choice of Machined Ceramic Components should reflect where and how the part works. We map application context to geometry, finish, and inspection so the part behaves as designed in real conditions.

Typical application areas for Alumina components

✅ Semiconductor fabrication equipment: Wafer handling and processing tools where purity and strength matter

✅ Medical and dental devices: Surgical instruments and implants relying on wear resistance

✅ Automotive and aerospace systems: High-stress assemblies exposed to heat, vibration, and corrosive environments

✅ Industrial machinery and automation: Bushings, rollers, and guides needing durability and precision

✅ Electrical and electronic devices: Insulators and substrates in high-voltage and RF systems

✅ Chemical processing equipment: Valves, seals, and components operating in aggressive media

• Capabilities and Tolerances (What You Can Expect)

Our typical capability window supports mainstream and advanced designs:

✅ Length up to ≤300 mm; outer diameter ≤150 mm

✅ Surface roughness Ra 0.02–0.2 for controlled friction and clean operation

✅ Minimum wall thickness 0.1 mm for lightweight structures

✅ Roundness 0.002 mm, concentricity 0.002 mm

✅ Straightness 0.004 mm, perpendicularity 0.005 mm

These values allow engineers to tighten alignment in guides, bushings, rollers, and precision fixtures without over-engineering the rest of the assembly. If you are targeting high-precision ceramic components for automation, these tolerances help maintain smooth motion and consistent force distribution.

Not every application needs the tightest tolerance or the finest finish. The right choice balances performance and lifecycle cost. Aim for the lowest surface roughness only where friction or cleanliness demands it; otherwise, use the tolerance that meets function while keeping cost in check. Define datums early. Map thermal and chemical loads to avoid over-specifying margins you will never use. The result is a robust part, a predictable budget, and a short path from drawing to production.

Ready to Specify with UPCERA?

Share a drawing, tolerance scheme, and your operating conditions. We will review manufacturability, confirm material fit, and suggest cost-saving adjustments - before you commit tooling. If you are replacing metal parts that fail early, we can match geometry and upgrade only the surfaces that matter.

Call to Action: Partner with UPCERA to select and produce Machined Ceramic Components that last longer and perform better. Contact our engineering team for a quick DFM review and a fast quote - and turn precision into uptime.

English

English 中文

中文