Custom Solid Ceramic Sleeve

Zirconia ceramic tubes are widely used in optical communications, semiconductors, medical equipment, precision instruments and chemical industries due to their high strength, high toughness and excellent wear resistance. Compared with other ceramic materials, zirconia has higher fracture toughness and impact resistance, and can operate stably for a long time under high temperature, high pressure and high corrosion environment. We provide different specifications, precision tolerances and special structure customization to meet the stringent application requirements.

- Solid structure for sealed designs

- Supports custom ferrule interfaces

- Excellent heat and wear resistance

- Precise internal diameter control

- Suitable for advanced applications

Custom Solid Ceramic Sleeve

Ceramic non-standard solid sleeve is built for applications requiring customized dimensions and superior material performance. Made from technical ceramics such as alumina or zirconia, it resists high temperatures, abrasion, and chemical attack. This component supports non-standard engineering solutions where precise tolerances and reliable insulation are needed. Commonly used in rotating assemblies, electrical systems, or as protective liners, the non-standard solid sleeve provides high strength and long service life. Its solid structure ensures mechanical integrity in harsh environments. Engineers favor it when standard sleeves don't meet the requirements of complex or innovative system designs.

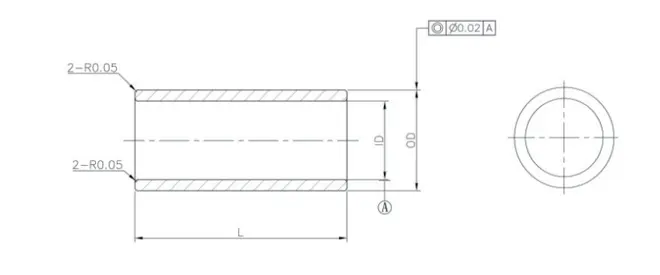

Technical Specifications

| Outer diameter: 1.0~10mm | Split: None |

| Inner diameter: 0.4~10mm | Pull force: None |

| Length: 1~20mm |

Please refer to our Processing Capability Table for the full range of processing capability.

Advantages of Custom Solid Ceramic Sleeve

- Precision Customization: Because ceramic sleeves can be tailored to exact dimensions and tolerances, they meet specific application and integration requirements.

- Exceptional Wear and Abrasion Resistance: As a result, they maintain surface integrity in high-friction or high-cycle environments.

- High Thermal and Chemical Stability: Therefore, they perform reliably in extreme temperatures and resist corrosion from acids, alkalis, and solvents.

- Electrical Insulation and Non-Magnetic Properties: In addition, they are ideal for electronic and magnetic-sensitive applications requiring isolation and neutrality.

- Dimensional Stability and Rigidity: Consequently, they provide consistent alignment and protection over long service life.

- Material Inertness and Cleanliness: Thanks to their non-reactive nature, they are suitable for cleanroom, biomedical, and high-purity environments.

Applications of Custom Solid Ceramic Sleeve

- Fiber Optic Connectors and Alignment Systems: For example, used to center and protect optical fibers in connectors and splicing assemblies.

- Medical and Laboratory Equipment: Because of their biocompatibility and precision, they are applied in surgical tools and diagnostic devices.

- Semiconductor and Electronics Manufacturing: In addition, they serve as insulators, guides, or protective sleeves in sensitive, high-purity systems.

- Aerospace and Defense Systems: Their strength and thermal stability make them suitable for structural support in extreme environments.

- Industrial Automation and Robotics: Used in bushings and linear guides where precision motion and wear resistance are critical.

- High-Temperature Insulation Assemblies: Lastly, they are integrated into kilns, reactors, and heating systems for mechanical protection and thermal isolation.

Applicable Industries

Enquire Now

- Welcome to contact us for more product information and quotes!

- Support customization according to drawings, quick response, short delivery guarantee!

- Consult Now

English

English 中文

中文