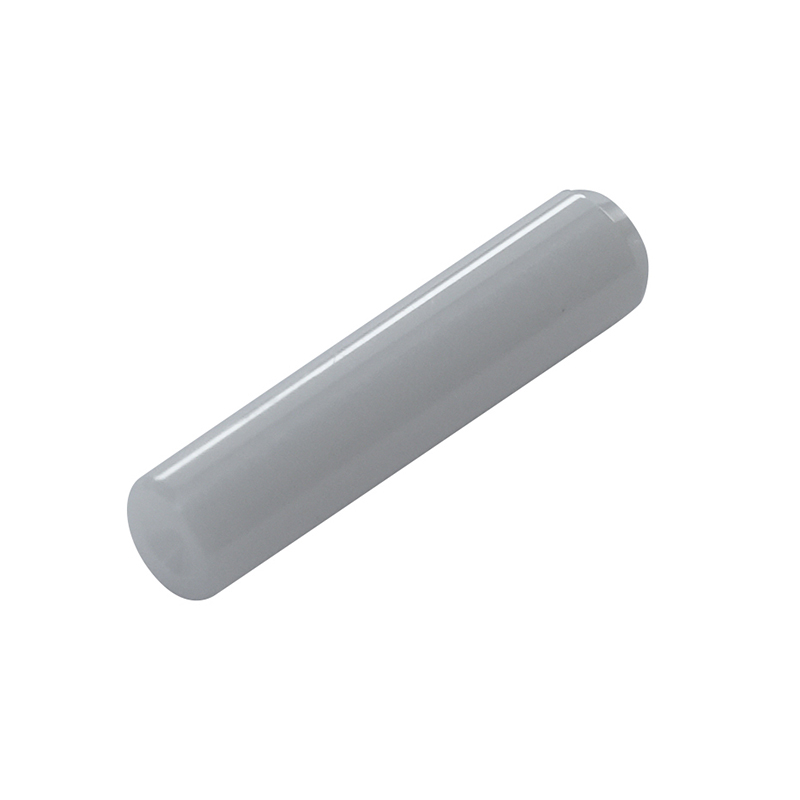

Zirconia Ceramic Roller

Zirconia ceramic roller is made of high-performance ceramic, featuring excellent high-temperature resistance, wear resistance, corrosion resistance, and high strength. Widely used in fluid transport, temperature protection, insulation support, and chemical equipment. We offer zirconia, alumina, silicon carbide, and silicon nitride in various sizes, with precision machining and custom structures to meet diverse needs.

- High temperature resistance & high strength – Suitable for high temperature conditions above 1000°C, long-term stable operation.

- Excellent corrosion resistance & insulation performance – Suitable for high acid and alkali, chemical fluid pipelines and electrical insulation applications.

- High-precision processing – Up to ±0.002mm, surface roughness Ra0.05 (specific accuracy depends on shape & material, see technical specifications below for details).

- A variety of shapes available – including open tubes, closed tubes, porous tubes, blind hole tubes, step tubes, rings, rollers, etc., and can be customized as required.

Zirconia Ceramic Roller

A zirconia ceramic roller delivers exceptional hardness, low friction, and chemical resistance. These zirconia ceramic rollers are used in conveyors, printers, and high-precision guiding systems under extreme wear conditions.

Technical Specifications

| Parameter | Typical Range |

| Length Range | ≤300mm |

| Outer Diameter | ≤150mm |

| Surface Roughness | Ra0.02-Ra0.2 |

| Minimum Wall Thickness | 0.1mm |

| Roundness | 0.002mm |

| Concentricity | 0.002mm |

| Straightness | 0.004mm |

| Perpendicularity | 0.005mm |

Please refer to our Processing Capability Table for the full range of processing capability.

Advantages of Zirconia Ceramic Roller

- Exceptional Wear and Abrasion Resistance: Because zirconia is extremely hard, the roller maintains its surface integrity even under continuous use and high contact pressure.

- High Fracture Toughness: As a result, it resists cracking and chipping better than most other ceramics, especially under mechanical stress.

- Thermal and Chemical Stability: Therefore, it performs reliably in high-temperature processes and corrosive environments.

- Low Friction Coefficient: Consequently, it reduces energy loss, heat buildup, and surface wear in dynamic systems.

- Precision Machining Capability: Thanks to advanced ceramic manufacturing, the roller can be produced with tight tolerances and smooth finishes.

- Non-Magnetic and Electrically Insulating: In addition, it’s suitable for use in magnetic-sensitive and electrically isolated applications.

Applications of Zirconia Ceramic Roller

- Textile and Paper Manufacturing: For example, it is used in guiding, tensioning, and transporting systems where wear resistance is essential.

- Metal and Wire Processing: Because of its hardness, it’s ideal for rolling, guiding, or shaping metal and wire with minimal surface damage.

- Semiconductor and Electronics Production: In addition, it’s used in cleanroom rollers or transport systems where contamination must be avoided.

- Medical and Pharmaceutical Machinery: Its chemical inertness makes it suitable for sterile conveying or rolling applications.

- Printing and Packaging Equipment: These rollers provide smooth, wear-resistant surfaces for consistent operation in high-speed systems.

- Industrial Automation and Robotics: Lastly, they are used in positioning, drive, and support functions where durability and precision are critical.

Enquire Now

- Welcome to contact us for more product information and quotes!

- Support customization according to drawings, quick response, short delivery guarantee!

- Consult Now

English

English 中文

中文