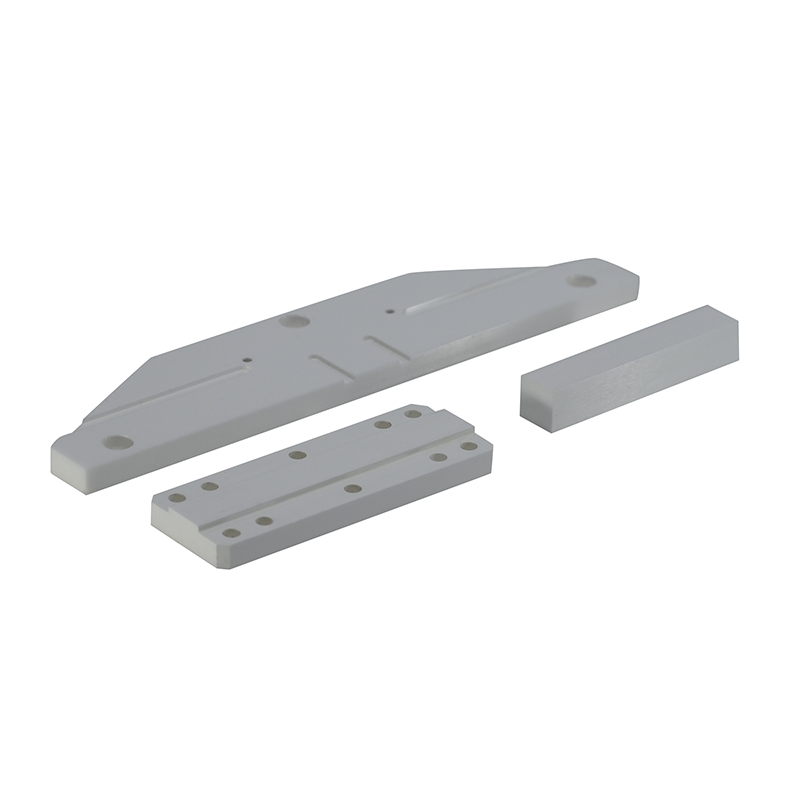

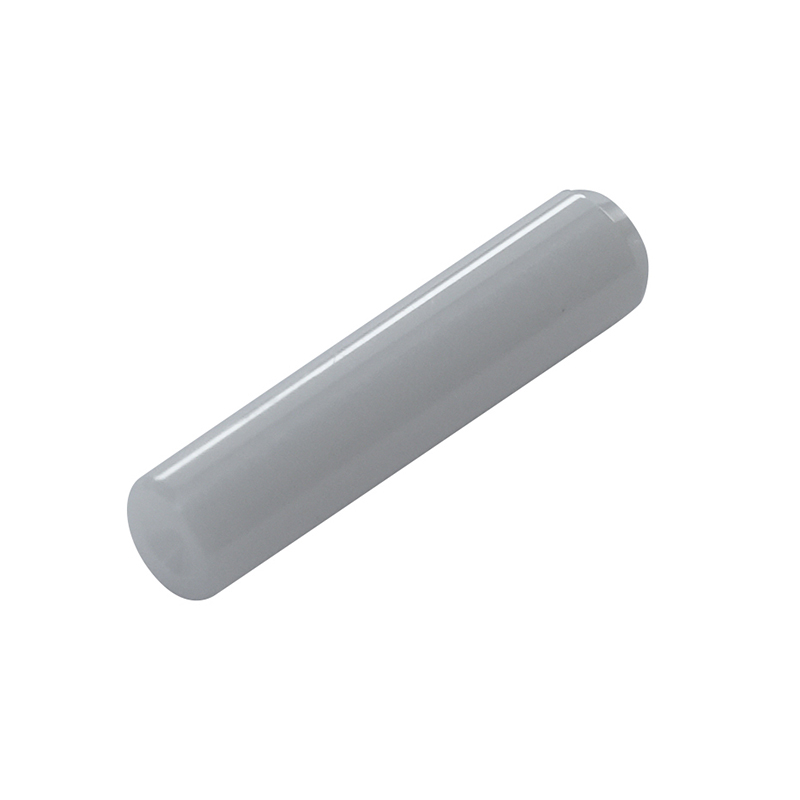

Precision Zirconia Ceramic Fixture

This zirconia ceramic fixture is designed for high-precision positioning, clamping, or support in demanding applications. With excellent hardness, wear resistance, and insulation, it ensures dimensional stability and surface integrity even under repeated mechanical or thermal stress. Ideal for semiconductor, optical, and medical industries.

- High hardness and wear resistance

- Excellent dimensional precision

- Non-conductive and non-magnetic

- Resistant to thermal shock

- Custom design supported

Precision Zirconia Ceramic Fixture

A precision zirconia ceramic fixture provides stable, heat-resistant positioning in machining, welding, or inspection tasks. Made from tough zirconia, this zirconia ceramic fixture maintains exact dimensions under mechanical stress and thermal variation. It's commonly used in semiconductor production, medical device manufacturing, and automated assembly lines requiring high-strength, non-metallic jigs or holders. The material's hardness and chemical inertness ensure reliable long-term performance.

Technical Specifications

| Parameter | Typical Range |

| Size Range | ≤400mm×400mm |

| Size Precision | ±0.005mm |

| Surface Roughness | Ra0.02-Ra0.2 |

| Flatness | 0.003mm |

Please refer to our Processing Capability Table for the full range of processing capability.

Advantages of Precision Zirconia Ceramic Fixture

- High Dimensional Accuracy: Thanks to advanced machining techniques, zirconia fixtures are crafted to exact tolerances for repeatable precision.

- Superior Hardness and Wear Resistance: As a result, they maintain their shape and surface integrity under frequent use and contact.

- Excellent Thermal and Chemical Stability: Therefore, they perform reliably in high-temperature or corrosive processing environments.

- Non-Conductive and Non-Magnetic: Because zirconia is electrically insulating and non-magnetic, it’s ideal for sensitive electronic and magnetic applications.

- Low Friction Surface: Consequently, it reduces component wear and enables smooth operation in mechanical holding or guiding applications.

- Longevity and Reliability: Due to its toughness and resistance to degradation, zirconia outlasts many metal and polymer alternatives.

Applications

- Semiconductor Manufacturing: Used in wafer alignment, etching, and deposition equipment for its precision and chemical resistance.

- Medical and Dental Equipment: Serves as a positioning or holding fixture in surgical tools and diagnostic devices requiring biocompatibility.

- Laser and Optics Systems: Provides stable, precise mounting for lenses and components where thermal expansion must be minimal.

- Electronics Assembly and Testing: Employed in PCB or chip placement systems where non-conductive, high-accuracy fixturing is critical.

- Research and Laboratory Instruments: Ideal for sample holders and precision platforms exposed to harsh reagents or high heat.

- Aerospace and Defense Testing Rigs: Integrated into assemblies where strength, wear resistance, and dimensional stability are essential.

Enquire Now

- Welcome to contact us for more product information and quotes!

- Support customization according to drawings, quick response, short delivery guarantee!

- Consult Now

English

English 中文

中文