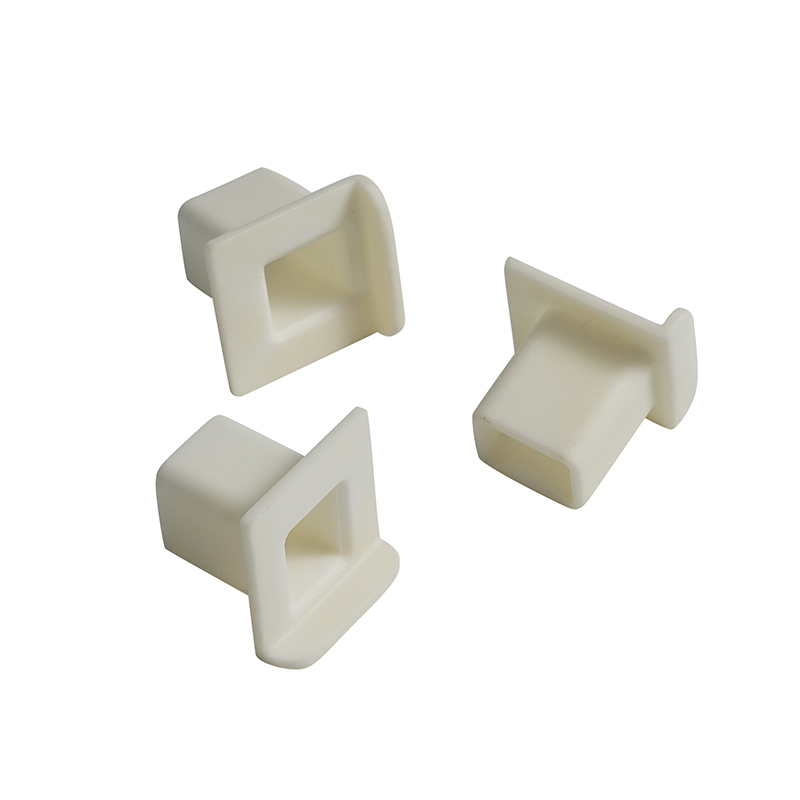

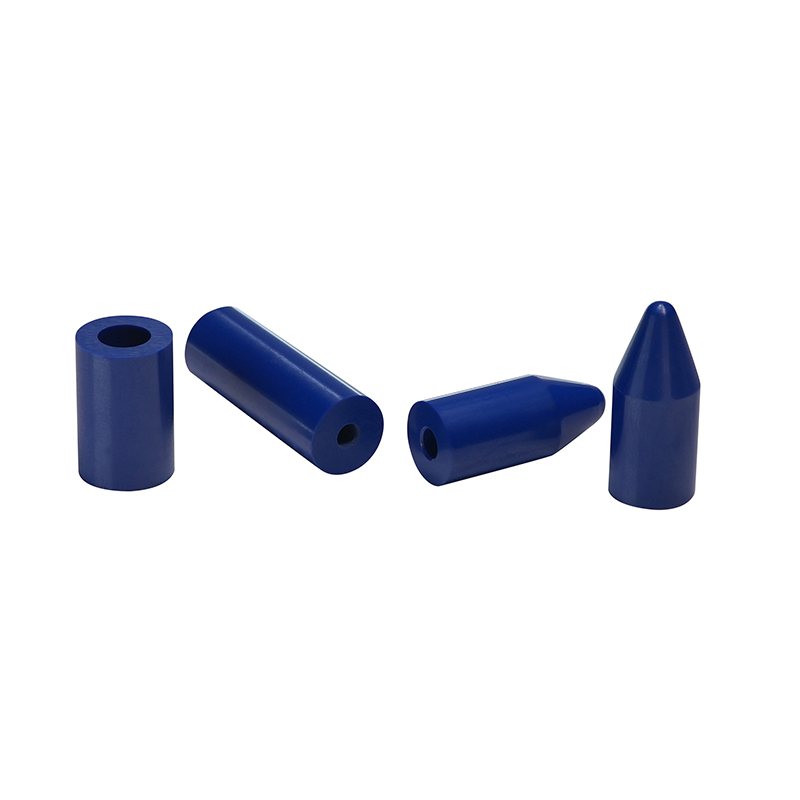

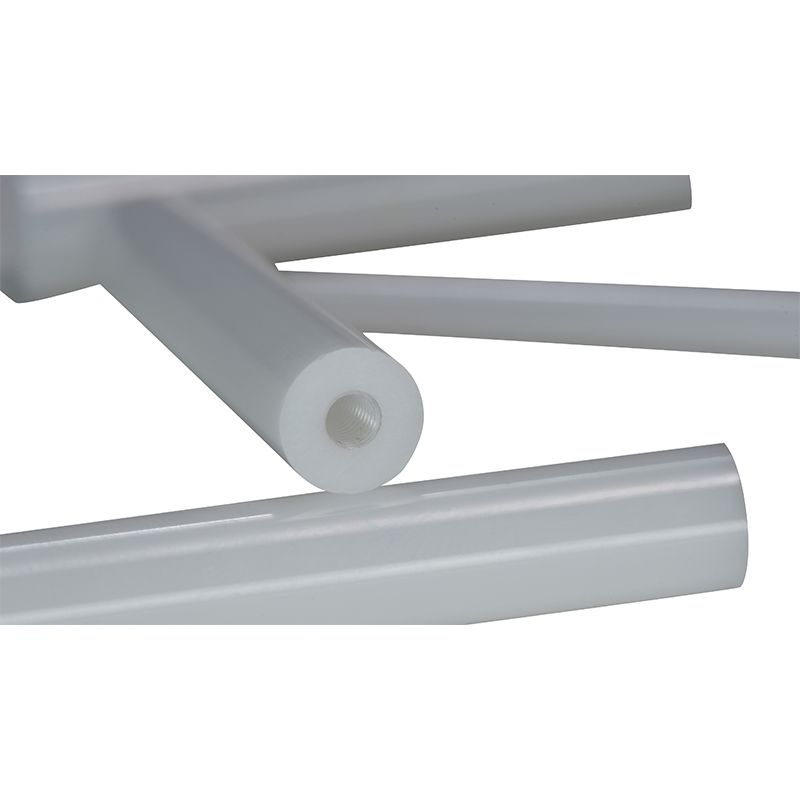

Zirconia Ceramic Structural Parts

Zirconia structural parts are engineered for high strength, durability, and resistance to wear, corrosion, and thermal shock. These components are ideal for demanding mechanical, electronic, and chemical environments, where both performance and reliability are critical.

- Factory-direct supply with guaranteed quality

- Custom designs, materials and complex geometries

- Precision-machined to tight tolerances

- Excellent wear, heat and corrosion resistance

- Stable supply with high-volume delivery capability

Zirconia Ceramic Structural Parts

Zirconia ceramic structural parts are precision-engineered components made from zirconium dioxide (ZrO₂), a robust and versatile ceramic known for its exceptional strength and durability. These materials offer high fracture toughness, outstanding thermal stability, and excellent resistance to wear and corrosion. Because of these properties, zirconia ceramics perform reliably in extreme environments, making them a preferred choice across demanding industries such as aerospace, automotive, medical, and industrial manufacturing.

Technical Specifications

| Parameter | Typical Range |

| Length Range | ≤300mm |

| Outer Diameter | ≤150mm |

| Surface Roughness | Ra0.02-Ra0.2 |

| Minimum Wall Thickness | 0.1mm |

| Roundness | 0.002mm |

| Concentricity | 0.002mm |

| Straightness | 0.004mm |

| Perpendicularity | 0.005mm |

Please refer to our Processing Capability Table for the full range of processing capability.

Advantages of Zirconia Ceramic Structural Parts

- Deliver Exceptional Mechanical Strength: Thanks to their high fracture toughness, zirconia components withstand heavy loads and resist cracking under pressure.

- Maintain Stability in High-Friction Environments: As a result, they perform consistently in dynamic applications such as rotating or sliding assemblies.

- Dimensional Accuracy Remains Intact Over Time: Even when exposed to thermal cycling or mechanical shock, they hold their form with precision.

- Furthermore, They Resist Corrosion and Thermal Degradation: This makes them highly reliable in chemically aggressive and high-temperature conditions.

- In contrast to metals, zirconia also acts as an excellent electrical insulator, which is essential in electronic and high-voltage systems.

- Moreover, Their Non-Magnetic Nature allows them to be used in magnetic-sensitive environments without interference.

- Additionally, Zirconia Minimizes Wear: By extending the service life of components, it reduces maintenance costs significantly.

- With Advanced Manufacturing Techniques, engineers can machine zirconia into complex geometries with extremely tight tolerances.

Applications of Zirconia Ceramic Structural Parts

- In Aerospace and Defense Applications, engineers rely on zirconia for structural components that endure intense vibration, temperature extremes, and pressure.

- For Medical and Dental Equipment, zirconia provides a durable, biocompatible material for surgical tools, prosthetics, and implant systems.

- Moreover, Semiconductor Manufacturing benefits from zirconia’s chemical purity and dimensional stability in wafer processing and cleanroom equipment.

- In Robotics and Industrial Automation, it plays a critical role in guiding systems, wear plates, and structural supports exposed to repetitive stress.

- Automotive Engineers Also Use Zirconia: Its resistance to heat and mechanical wear makes it ideal for sensor housings, exhaust system parts, and valve components.

- Finally, in Energy and Environmental Systems, zirconia supports high-performance components like insulators, fuel cells, and catalytic converters that operate under extreme stress.

Enquire Now

- Welcome to contact us for more product information and quotes!

- Support customization according to drawings, quick response, short delivery guarantee!

- Consult Now

English

English 中文

中文