Stop Frequent Replacements with Durable Advanced Ceramic Valve Disc

Advanced Ceramic Valve Disc technology turns chronic valve failures into predictable, low-touch operation. Plants in water treatment, chemicals, and power generation often live with leakage, drift, and unplanned stoppages that quietly drain budgets. As a manufacturer, UPCERA specializes in customizing and processing advanced ceramic materials so every disc is built for the real conditions you face - your media, your temperature window, your duty cycle.

The Hidden Cost Of "Good Enough" Valves - And How Ceramics Break The Cycle

Most replacement cycles don't start with a dramatic crack. They begin with subtle symptoms: a valve that needs more torque, a seal that seeps only at certain temperatures, a control loop that never quite settles. Metal and polymer parts lose their finish when abrasive particles score the surface. Chemicals attack the substrate. Thermal cycling opens clearances that used to be tight. Maintenance teams swap components, yet the root cause - the worn sealing interface - returns sooner each time.

An Advanced Ceramic Valve Disc tackles that interface head-on. Dense microstructure and high surface hardness resist abrasion. A smooth, polished face minimizes micro-leak paths. Dimensional stability keeps the sealing geometry consistent across hot starts, cold rinses, and everything between. The result is not just fewer interventions - it's steadier flow, lower actuator load, and setpoints that hold.

✅ Pain points our customers bring to us

• Frequent leakage after abrasive duty cycles

• Corrosion from aggressive media and cleaning agents

• Seal instability during start-ups and thermal shocks

• Rising torque, galling, and surface scoring over time

• Escalating labor and spares tied to short service life

These failures are predictable under the wrong materials. They are also preventable with the right ones. That's why UPCERA begins every project by mapping your process: the fluid, the solids content, the temperature range, and the cycling pattern. Then we design a disc to remove the specific failure mode you keep paying for.

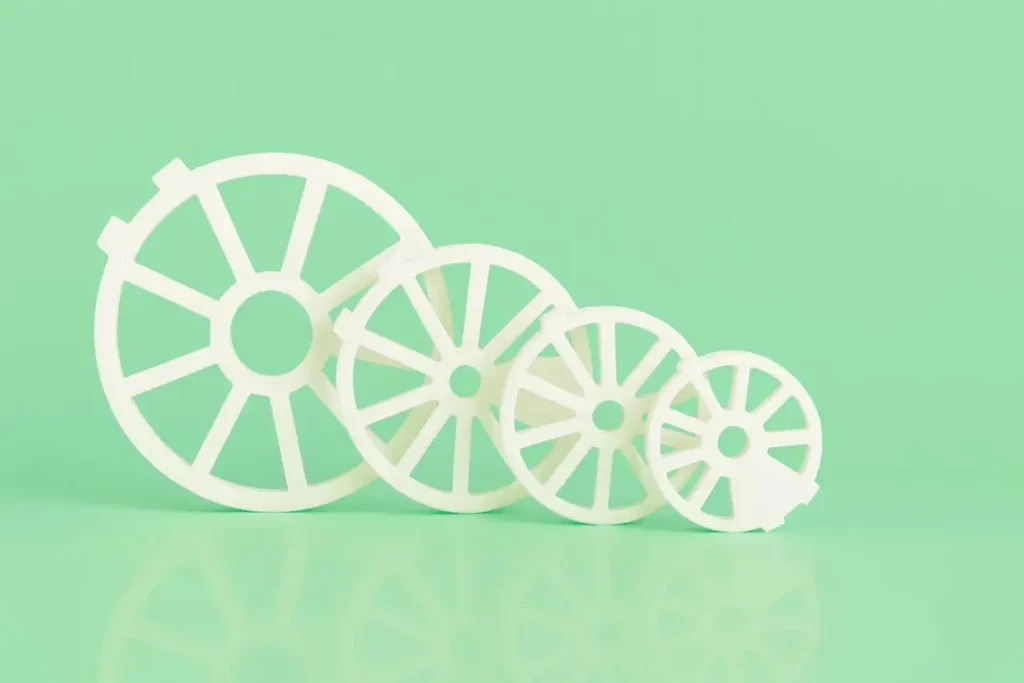

Inside An Advanced Ceramic Valve Disc

UPCERA engineers work primarily with alumina and zirconia - two ceramics proven in harsh, high-cycle environments. Each brings a different strength profile. Alumina offers outstanding hardness and wear resistance. Zirconia adds fracture toughness and impact resilience for rapid cycling or pressure shocks. Both are chemically inert, corrosion resistant, and thermally stable.

- Material Advantages At A Glance

✅ Alumina (Al₂O₃)

- Exceptional hardness to resist abrasion and erosion

- Smooth surface for tight, low-friction sealing

- Stable dimensions under hot–cold fluctuations

✅ Zirconia (ZrO₂)

- High toughness for cycling and impact loads

- Reliable sealing faces that resist chipping

- Compatible with steam, slurries, and aggressive media

But material is only half the story. Geometry and finish matter just as much. UPCERA controls flatness, parallelism, and edge chamfers so the disc seats cleanly and distributes load across the face. We finish to the surface roughness your seal requires - fine enough to stop bypass leakage, durable enough to keep that finish in service. For valves that see solids, we tune the profile to shed particles rather than trap them.

❓ Why this design approach works:

Short service life usually stems from a mismatch between sealing mechanics and operating reality. A disc that is too soft polishes away. A face that is too rough creates micro-channels. A geometry that ignores thermal expansion loses contact pressure. By aligning Advanced Ceramic Valve Disc material, finish, and tolerances with your process envelope, we protect the sealing interface - the place where reliability is won or lost.

- Typical Use Cases Where Ceramics Shine

• Water and Wastewater Treatment: particle-laden flows and chemical dosing.

• Chemical Processing: corrosive media, solvents, and cleaning cycles.

• Power And Steam Service: repeated thermal cycling and pressure swings.

• Sanitary Equipment: hygienic, inert surfaces that resist contamination.

• HVAC And Hot Water Systems: thermostatic and pressure-balancing valves.

Long-tail search terms customers use to find us include "ceramic valve disc for abrasive media" and "custom alumina valve disc". If those phrases describe your challenge, ceramics are likely the right move.

Your Roadmap With UPCERA

Switching to ceramics is a reliability upgrade, not a gamble. We make the path concrete and low risk.

1) Identify The Right Candidate

Start with valves that fail early, run abrasive fluids, or leak under temperature swings. Quantify current life, torque trend, and leak rate. This baseline becomes your ROI metric.

Tell us the fluid chemistry, temperature range, pressure, cycling frequency, and cleanliness requirements. The more real-world detail we have, the better we can tune your Advanced Ceramic Valve Disc.

3) Engineer The Fit

UPCERA designs geometry, hole patterns, and tolerances to match your seat, cage, or plug. We target a surface finish that balances low friction with long wear life. Prototype parts verify stack-ups and sealing load.

4) Validate In Service

Run a controlled pilot. Track torque, leakage, and cycle count. In steam or thermal-shock applications, observe start-up behavior. Most customers see immediate gains: steadier control, quieter actuators, cleaner starts.

5) Scale With Confidence

Once validated, standardize the disc across similar valves and lines. Predictable performance reduces emergency spares and turns maintenance windows into scheduled, efficient work.

✅ What improvements to expect

- Longer intervals between replacements

- Lower torque and fewer actuator issues

- Reduced leakage and cleaner process control

- Smaller spares inventory and less firefighting

- Measurable drop in total cost of ownership

Why UPCERA: We are not a catalog - we are a ceramics manufacturer focused on customization and processing. That means tight dimensional control, traceable quality, and surfaces finished for sealing, not just appearance. It also means you work with engineers who speak the language of duty cycles, pressure drops, and valve dynamics.

Call To Action

Ready to stop living with "good enough"? Request a consultation with UPCERA. We'll assess your operating conditions and recommend an Advanced Ceramic Valve Disc built for your media, temperature range, and cycle profile. Expect fewer leaks, longer life, and steadier flow - backed by engineering, not guesswork.

Talk to UPCERA today and turn valves from a recurring expense into a dependable asset.

English

English 中文

中文