How Does Alumina Ceramic Machining Support High Accuracy

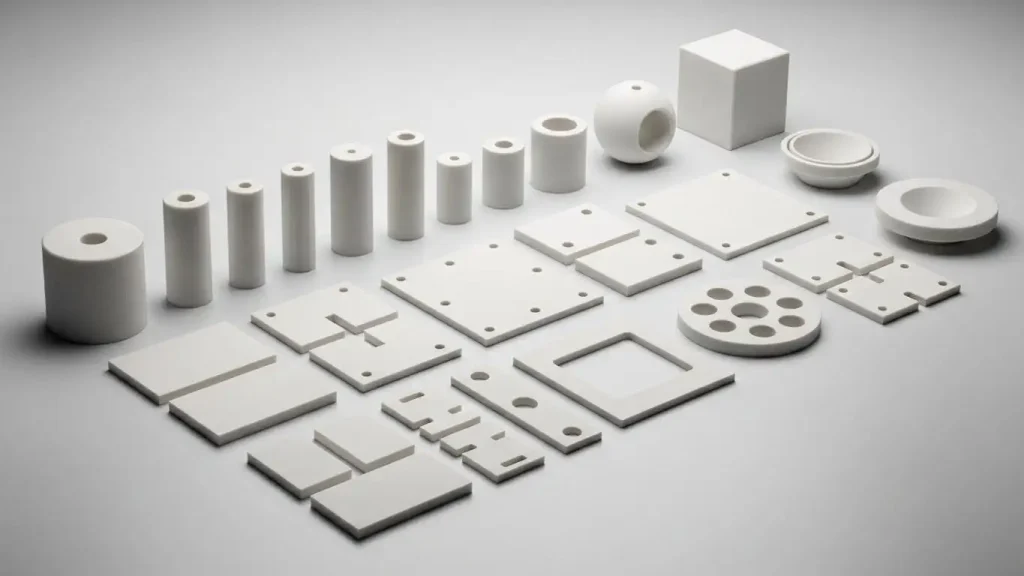

Alumina Ceramic Machining is behind many of the small, high-precision parts that keep modern equipment running smoothly. From semiconductor tools to medical devices, these components usually sit deep inside the machine, quietly handling heat, friction, and aggressive chemicals while everything else depends on them. At its core, Alumina Ceramic Machining is the controlled process of forming, sintering, grinding, and polishing high-purity alumina into reliable, dimensionally stable parts.

What makes this process so effective in real applications? And why do so many projects end up moving away from metal or polymer parts toward alumina after the first rounds of testing? Let's break it down in practical terms.

Why Alumina Ceramic Machining Supports True Precision

Alumina (Al₂O₃) is a technical ceramic known for three main attributes: hardness, wear resistance, and stability at elevated temperatures. When those inherent material properties are combined with a tightly controlled Alumina Ceramic Machining process, you get parts that hold their shape and function over a very long service life.

Metal components, especially in dynamic or high-temperature systems, can slowly deform. They may bend under load, creep at temperature, or change shape after repeated thermal cycling. Polymers face their own limits, such as softening, rapid wear, or dimensional drift. Alumina behaves differently. It remains remarkably stable - even in equipment that heats up and cools down many times a day.

For design engineers, this stability is more than a nice-to-have. It translates into:

•Less drift in critical dimensions

•Fewer alignment issues over time

•More predictable performance across the full life of the machine

When tolerances stack up across multiple parts, a small gain in stability at the component level can make the difference between a system that needs constant tweaking and one that "just runs.”

What Precision Looks Like in Numbers

At UPCERA, Alumina Ceramic Machining is treated as a complete process chain, not a single isolated step. It begins with high-purity raw powder and continues through forming, sintering, precision grinding, and final finishing. When each stage is controlled, the output can look like this:

- Surface roughness down to roughly Ra 0.02 - 0.2 μm for smooth sliding, sealing, or guiding

- Minimum wall thickness around 0.1 mm for compact, lightweight designs

- Geometric tolerances - roundness, concentricity, straightness - managed in the ~0.002 - 0.005 mm range, depending on the feature

On paper, these values are just numbers. In real assemblies, they're what allow multiple parts to line up within only a few microns. Without this level of control in Alumina Ceramic Machining, even a well-thought-out design can struggle to hit its performance targets.

Why Projects Move Away from Metals and Polymers

A lot of applications reach UPCERA after other materials have already been tried. The patterns are surprisingly consistent across industries.

1. Wear and surface damage

In fast-moving or abrasive environments, metal parts may scratch, seize, or deform. Polymers can wear quickly or change properties as temperature rises. Once surfaces start to change, clearances grow, friction shifts, and accuracy drops. Alumina components produced through Alumina Ceramic Machining resist abrasion and preserve their geometry for much longer, helping the process stay stable.

2. Thermal distortion

Applications such as high-temperature furnaces, power modules, and rapidly switched systems expose parts to constant heating and cooling. Conventional metals respond by expanding, contracting, and slowly moving out of their original position. The result is misalignment and growing scatter in key dimensions. Thanks to its thermal stability, alumina helps precision features, reference faces, and sealing lands remain fixed where the design requires them.

3. Corrosion and contamination

In environments like chemical processing, semiconductor fabrication, and medical technology, components must survive aggressive chemistries and remain free from contamination. Alumina components produced via Alumina Ceramic Machining offer chemically inert, non-rusting surfaces that support cleaner processes and more stable product quality. Corroded metal sheds particles and can release ions that contaminate the product or medium. Alumina ceramics resist many acids and alkalis, do not rust, and do not leach metal ions, making them a good fit for sensitive, tightly controlled processes.

When customers switch to Alumina Ceramic Machining for critical parts, they often see:

•Longer service life and fewer unexpected replacements

•More stable dimensional accuracy over many cycles

•Cleaner, more inert surfaces near the product flow

•Reliable electrical insulation in high-voltage or RF systems

In practice, this can mean bushings that don't ovalize under load, rollers that keep their diameter over millions of rotations, valve components that survive harsh media, or insulators that stay robust in high-power assemblies.

How UPCERA Builds Accuracy into Each Alumina Part

From UPCERA's perspective, accuracy is not a label added at the end - it is something designed into the Alumina Ceramic Machining route from the first step.

We routinely produce alumina parts up to about 300 mm in length and 150 mm in outer diameter, while holding geometry in the low-micron range. Features such as straightness, perpendicularity, and concentricity are controlled in the neighborhood of 0.002 - 0.005 mm, depending on the design and its role in the assembly. For customers, the advantages are easy to see:

•Reliable, repeatable fits in demanding assemblies

•Consistent performance from lot to lot, simplifying qualification

•Less downtime tied to mechanical adjustments or repeat calibration work

Reaching these results with alumina is not a simple machining task. The combination of high hardness and brittleness makes process control critical. Successful Alumina Ceramic Machining depends on purpose-built grinding and polishing systems, carefully selected abrasives, and people who understand the ceramic's behavior in detail. At UPCERA, engineering and production teams work together to build part-specific machining windows and inspection plans, rather than running everything under the same standard process.

Design Collaboration: Starting Precision on the Drawing

Accuracy doesn't start at the grinder; it starts in the CAD model. Many engineers know exactly what they want from a performance point of view but are less familiar with the design rules specific to Alumina Ceramic Machining.

That's why UPCERA often gets involved before the first prototype is cut. The kind of design support we provide usually includes:

•Analyzing wall thickness, fillet geometry, and tolerance schemes for compatibility with Alumina Ceramic Machining

•Identifying which faces and interfaces genuinely need ultra-low roughness values

•Recommending modest geometry updates that boost yield and keep machining budgets under control

Very small changes can have outsized effects. A softened edge, a repositioned feature, or a slightly adjusted tolerance band can turn a difficult-to-produce item into a stable, repeatable ceramic part. Addressing these points at the beginning helps avoid quality issues later and shortens the development cycle.

Many Alumina Ceramic Machining projects start with just a few parts on a drawing: a prototype for a new high-precision tool, a test series for a medical platform, or components for an experimental line. The real performance benchmark comes when those same parts must be produced consistently, month after month, at higher volumes.

UPCERA structures its process so that the principles used for one-off parts also apply to regular series production. Stable process windows, standardized workflows, strict material control, and inspection plans aligned with the final assembly's tolerance stack-up all play a role. This gives customers confidence that the performance seen in the first trial won't disappear when the order grows from tens of parts to thousands.

Is It Time to Rethink Your Material Choice?

If you're seeing recurring wear, drift, or contamination in your current setup, the root cause may not be the design at all. The challenge you are facing may simply be that the current material has reached its limits. With Alumina Ceramic Machining, you can move to components that deliver greater stability and longer service life in harsh environments - without giving up micron-level precision.

For UPCERA, Alumina Ceramic Machining is more than a process - it's an enabling technology for dependable, high-accuracy systems used in real-world production environments. If your current components are limiting accuracy or causing unplanned downtime, alumina is a strong candidate for your next redesign.

Share your design files and application requirements with UPCERA's engineering team, and we'll work with you to turn demanding specifications into stable, long-term performance in the field.

English

English 中文

中文