How Alumina Ceramic Stepped Ring Improves Equipment Lifespan?

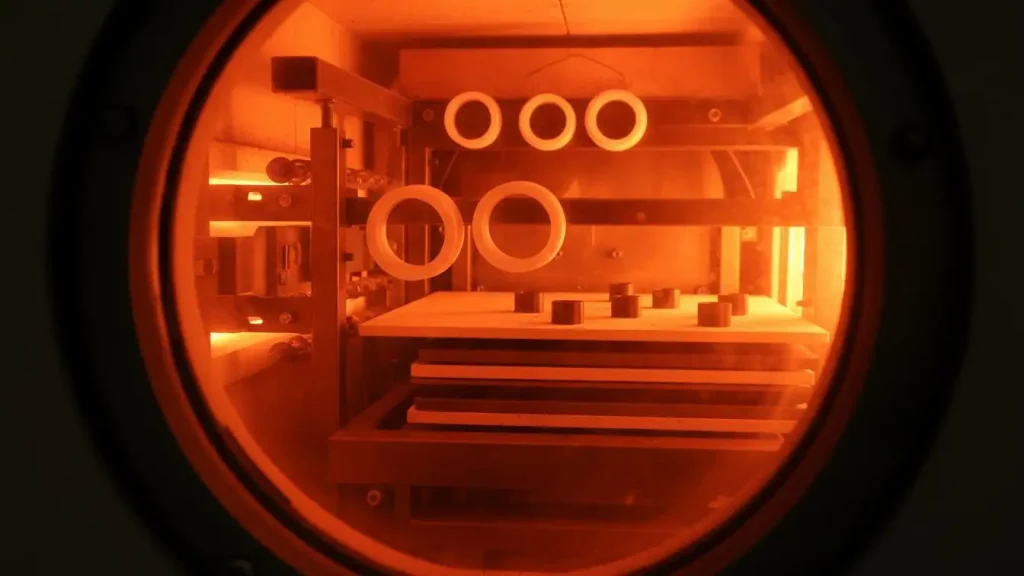

In many factories, big failures often start from a very small part. Alumina Ceramic Stepped Ring is one of those "quiet" components that most people never notice. It is a precision ceramic ring with a stepped structure, used to position, seal, or insulate parts inside pumps, valves, and other critical equipment. It works in high temperature, high wear, and corrosive environments where metal and plastic parts struggle. Why can this tiny ring have such a big impact on equipment lifespan? In this article, we will take a closer look.

Why This Small Ring Has Such a Big Impact

In most factories, the real pain is not the cost of a spare part. The real pain is what happens when a line stops:

production loss, emergency repair work, overtime labor, and sometimes wasted product. A worn ring here, a small leak there - and suddenly the whole process is down.

That is exactly the kind of hidden problem an Alumina Ceramic Stepped Ring is designed to solve.

Instead of standard metals or plastics, the ring is made from high-performance alumina ceramic. This gives it a combination of properties that is hard to match:

✅ Stable performance at temperatures above 1000°C

✅ High hardness and strong wear resistance under continuous friction

✅ Resistance to many acids, alkalis, and aggressive chemical media

✅ Reliable electrical insulation for high-voltage or sensitive systems

Unlike metal, alumina does not rust, soften, or creep when the temperature rises. It holds its shape over a long period of time. The stepped structure allows it to do more than a simple ring: it can locate parts, create precise gaps, and support sealing surfaces in a compact design.

At UPCERA, we machine each Alumina Ceramic Stepped Ring to tight tolerances. Typical roundness and concentricity are in the range of 0.002 mm, with refined surface roughness when needed. This precision means less vibration, more stable running, and lower stress on the surrounding components.

How Alumina Ceramic Stepped Ring Protects Equipment Life

- Fighting Wear And Misalignment

One of the most common stories we hear is very similar:

a customer uses metal spacers or rings, and after a few months they see misalignment, noise, and rising vibration levels. When they open the equipment, the rings are worn and out of shape.

When you replace conventional metal rings with an Alumina Ceramic Stepped Ring, the wear pattern changes:

✅ The hard ceramic surface resists scratching and abrasion

✅ Tight tolerances are maintained over long service life

✅ Thin sections make integration easy in dense assemblies

Because the ring does not deform or wear easily, seals and moving parts stay where they should be. Progressive loss of alignment is reduced, and the usual chain reaction of damage inside the machine slows down. The end result is longer-running pumps, motors, and valves, and fewer surprise stoppages.

- Handling Heat, Chemicals, And Harsh Media

Many process engineers face a difficult choice when they select ring materials:

• Hard metals wear well, but can corrode or oxidize in aggressive media.

• Corrosion-resistant metals survive chemicals, but may soften or deform at high temperatures.

• Polymers are easy to machine, but often cannot handle either heat or long-term friction.

Here, the Alumina Ceramic Stepped Ring offers a different path. Alumina ceramic stays strong at elevated temperatures and resists many chemical attacks at the same time. Its low thermal expansion also helps maintain stable dimensions when conditions change.

Typical use cases include:

• Sealing and spacing parts in chemical process lines

• Isolation components exposed to hot, reactive gases or liquids

• Rings and spacers in semiconductor or high-purity equipment

In these environments, metal parts may pit, oxidize, or slowly deform, which can cause leakage or contamination. The alumina ring, by contrast, keeps a smooth, hard surface. This stability directly supports longer equipment life and more consistent product quality.

- Supporting Sealing And Electrical Safety

Another weak spot in many designs is the interface between mechanical and electrical functions. For example, you may need a ring that:

• Holds a seal in the right position

• Carries mechanical load

• Also provides electrical insulation between parts

Because alumina is both a strong structural material and an excellent insulator, the Alumina Ceramic Stepped Ring can take on this multi-role function. In practice, it can:

• Serve as a precise seal seat, reducing leakage and protecting softer seal faces

• Act as an insulating spacer in high-voltage connectors or sensor assemblies

• Help prevent tracking and arcing in compact layouts

When these interfaces remain stable, you avoid two big risks at once: mechanical failure and electrical failure. That means fewer unexpected shutdowns, safer operation, and better long-term reliability for your equipment.

Why Partner with UPCERA for Alumina Ceramic Stepped Rings

From UPCERA's point of view, a successful Alumina Ceramic Stepped Ring is never just a catalog item. It is the result of matching ceramic properties, ring geometry, and machining precision to the real working conditions of your application.

Here is how we typically support our customers:

✅ From Alumina To Advanced Ceramics

Most designs begin with alumina due to its strong overall balance. When the working environment is more extreme, we evaluate zirconia, silicon carbide, or silicon nitride as alternatives. Our role is to guide you to the best material for your process, rather than simply selling what is easiest to produce.

✅ Tailored sizes and shapes

We can produce rings over a broad size range, with lengths up to around 300 mm and outer diameters around 150 mm, depending on the design. Complex geometries are no problem: steps, grooves, through-holes, and chamfers can be combined to make the ring match your existing layout exactly.

✅ High-precision ceramic machining

By using advanced ceramic machining, we routinely reach tolerances of about ±0.002 mm on critical features. This fine control ensures that each Alumina Ceramic Stepped Ring positions components accurately in high-speed, high-pressure, or vacuum systems.

✅ Engineering support, not just parts

We work with your drawings and real-world conditions. That includes temperature profile, media, expected load, and target lifetime. Based on that, our team can recommend ceramic grades, tolerances, and surface finishes that make sense for your equipment instead of adding unnecessary cost.

If you are dealing with frequent wear, small but repeated leakages, or insulation issues in pumps, valves, electrical systems, or chemical and semiconductor equipment, it may be time to rethink that "simple" ring in the middle of the assembly.

An Alumina Ceramic Stepped Ring from UPCERA can be a quiet upgrade that delivers visible results: longer service life, fewer emergency stops, and more predictable maintenance planning.

Call to Action

Ready to see how this could work in your own plant?

Reach out to UPCERA for a technical review, drawing evaluation, or trial batch of Alumina Ceramic Stepped Rings. Share your operating conditions with us, and we will help you design a ceramic solution that keeps your equipment running longer, safer, and more efficiently.

English

English 中文

中文