What Manufacturers Need from a Trusted Ceramic Material Supplier

Ceramic Material Supplier choice often decides whether a build ships on time, meets spec, and stays on budget. At UPCERA, we see how small gaps in material selection, processing, or quality control can snowball into scrap and delays. We approach every project with one aim: remove uncertainty early and keep performance stable at scale. This article shares what manufacturers actually need from a trusted partner - and how we meet those needs with disciplined engineering and transparent execution.

Pain Points a Ceramic Material Supplier Must Solve

- Quality, Cost, and Lead Time Work as One System

When quality drifts, costs rise. When tolerances slip, assembly halts. When schedules slip, revenue moves out. The three pillars are linked. A dependable Ceramic Material Supplier protects all three. We were the first company in China to independently develop zirconia ceramic sleeves for optical communication. Since day one, we have held a strict quality stance. That discipline supports our role as a recognized producer of zirconia sleeves and ferrules used in optical communication connectors, optical modules, computing power centers, and data centers.

Our method is simple but rigorous. We link design, material selection, and manufacturing from the first conversation. We assess required loads, surfaces, and environments. We then align microstructure, geometry, and finishing with those needs. The goal is predictable yield and repeatable performance.

• Tight process windows for dimensional stability and surface finish

• Clear guidance on matching material to environment and load case

• End-to-end traceability with consistent batches across lots

• Compliance readiness: ISO 9001, ISO 14001, ISO 45001, REACH, RoHS

• Agile R&D support to prevent late-stage rework

- Early Risk Reduction Starts in Design

Real savings show up before the first prototype. We review drawings for tolerance stack-ups and polishing allowances. We flag risk in thin walls, sharp transitions, or mixed materials. We suggest design tweaks that keep strength high and wear low. Lean experience from large-scale sleeve and ferrule production helps us move from concept to repeatable output, with fewer surprises and fewer ECO cycles.

Capabilities Manufacturers Need from a Trusted Ceramic Material Supplier

1) Materials and Processes That Scale

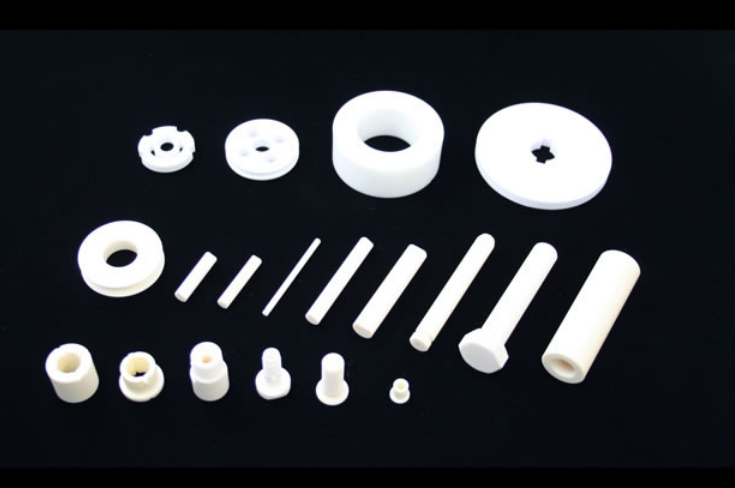

Different advanced ceramic materials do different jobs. Versatility matters. We customize and process zirconia, alumina, ruby, sapphire, aluminum nitride, silicon nitride, and silicon carbide. We choose each material for its mechanical, thermal, electrical, or optical edge. We then tailor grain size, density, and finish to the application. Our focus is not only peak properties but also stability under volume.

Since 2017, we have expanded into multiple industries and specialized structures. Our components serve semiconductors, aerospace, healthcare, new energy, mechanical engineering, chemicals, consumer electronics, and wearable technology. This range keeps our advice grounded. We know what survives corrosive chemistries. We know how parts react to thermal cycling or high RPM. We also know where the trade-offs hide, such as between toughness and hardness or between conductivity and insulation.

For data-intensive markets, we build precision ceramic components for data centers where alignment, wear resistance, and thermal behavior define uptime. In optical communication, our zirconia sleeves and ferrules anchor reliable links across modules and systems. The theme is consistent: robust materials knowledge, stable processes, and measured change control.

2) R&D Depth and Source Control

Our R&D roots trace to Tsinghua University's ceramics expertise. The team moves fast but stays evidence-based. We design experiments that answer one question at a time. We validate with metrology and real-world tests. Through deep collaboration with Sinocera, we reinforce source R&D and quality control. Over time, we have independently developed more than ten categories of ceramic materials, covering hundreds of types and tens of thousands of products. This is more than a catalog. It is a library of proven routes that can shorten your qualification path and reduce risk in scale-up.

Partner with UPCERA

Manufacturers want fewer variables and more certainty. We provide integrated, customized solutions from early design input and material selection to precision manufacturing and ramp. Our quality system and international certifications keep output consistent and audit-ready. We measure success in stable yields, clean Cpk data, and predictable lead times.

We also respect real-world constraints. Every application has limits on geometry, assembly, inspection, and schedule. Our job is to align material behavior and process capability with those realities. We plan for polishing allowances, fixturing, and inspection methods. We communicate clearly, especially when trade-offs are required.

✅ Consider us when you need:

• Application-driven material selection across zirconia, alumina, sapphire, AlN, Si₃N₄, and SiC

• Lean, repeatable manufacturing with tight tolerances and smooth finishes

• Fast R&D response that compresses prototype-to-volume timelines

• System-level thinking for optics, power, thermal, and mechanical interfaces

• A partner recognized for zirconia sleeves and ferrules, backed by strict quality control

Not every problem demands a new design. Sometimes a small change in chamfer, polish, or sintering cycle unlocks yield. Sometimes a switch from alumina to zirconia adds toughness without changing the envelope. Sometimes silicon nitride or silicon carbide is the right path for high-temperature or high-speed use. We bring options, with data.

As a Ceramic Material Supplier, we do more than ship parts. We remove friction from your program. We help you avoid late changes. We make production predictable. That is how budgets hold and schedules stay intact.

Final Words

If you are qualifying new ceramic components - or troubleshooting yield, wear, or alignment issues - talk to us. Contact UPCERA to schedule a material selection session or a design-for-manufacturing review. Together we can reduce risk, accelerate qualification, and deliver stable performance at scale.

English

English 中文

中文