What Makes Ceramic Mechanical Parts Ideal for Corrosive Environments

As operating conditions become more demanding, Ceramic Mechanical Parts are emerging as the go-to alternative to metal components that rust, bend, or fail too often. UPCERA serves automation lines, lab equipment makers, chemical facilities, and semiconductor manufacturers that all operate under the same pressures: aggressive chemicals, high temperatures, and constant moisture that push conventional metal parts beyond their limits.

The Limits of Metal in Harsh Environments

In many industrial systems, corrosion is not a one-time event but a constant background process. A stainless-steel fitting or bracket that looks flawless at installation can start to rust, pit, or react with the process medium after only a short time in service. Threads that once turned smoothly begin to seize. Sealing surfaces lose their finish. Insulating parts absorb moisture or suffer chemical attack, and their electrical properties slowly drift.

None of this usually happens overnight, which makes it even more disruptive. Small changes accumulate into frequent inspections, unplanned shutdowns, higher scrap rates, and a maintenance schedule driven more by emergencies than by planning. When equipment must operate close to chemicals, hot gases, or aggressive cleaning agents, the basic assumptions behind metal components start to break down.

Why Ceramic Mechanical Parts Behave Differently

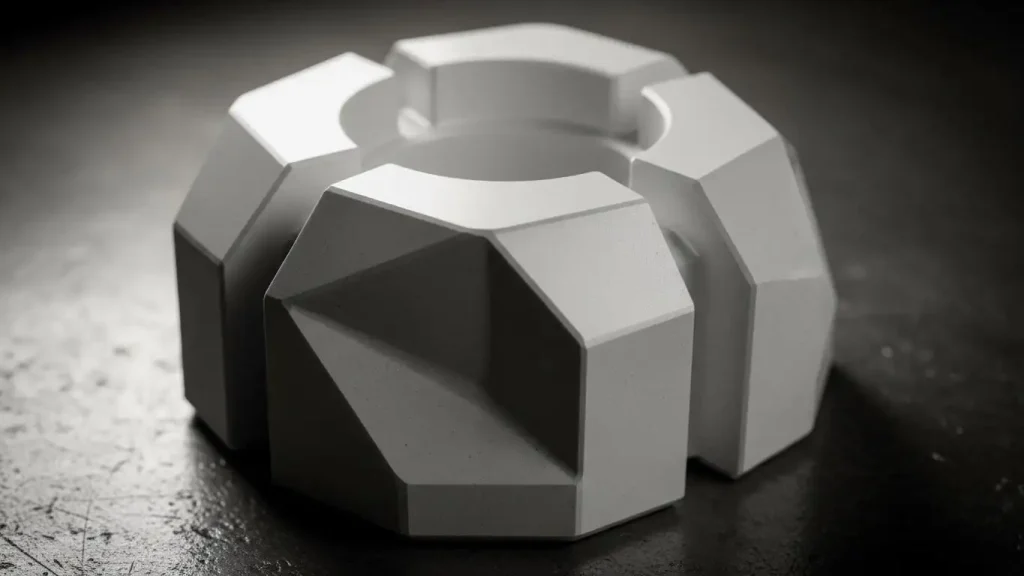

Ceramic Mechanical Parts made from high-purity alumina address these problems at the material level. Rather than starting with a reactive metal and trying to protect it with coatings or special alloys, UPCERA begins with alumina, a material that is inherently stable. Alumina does not rust and is highly resistant to many acids, alkalis, and solvents used in industrial and chemical processing. For designers, this stability is a major advantage in dosing units, precision fluid paths, and fixtures inside hot or chemically aggressive chambers where material changes directly affect process accuracy.

Temperature is the second major challenge. Many metals that tolerate a corrosive medium will still soften, scale, or creep under prolonged heat. Alumina ceramics maintain their mechanical strength and surface quality at elevated temperatures while also providing strong electrical insulation. For operators, Ceramic Mechanical Parts mean components that stay within tolerance longer, hold alignment, and preserve insulation performance across repeated thermal cycles. That directly reduces recalibration work and the risk of drift in sensitive instruments.

What Sets UPCERA Ceramic Mechanical Parts Apart

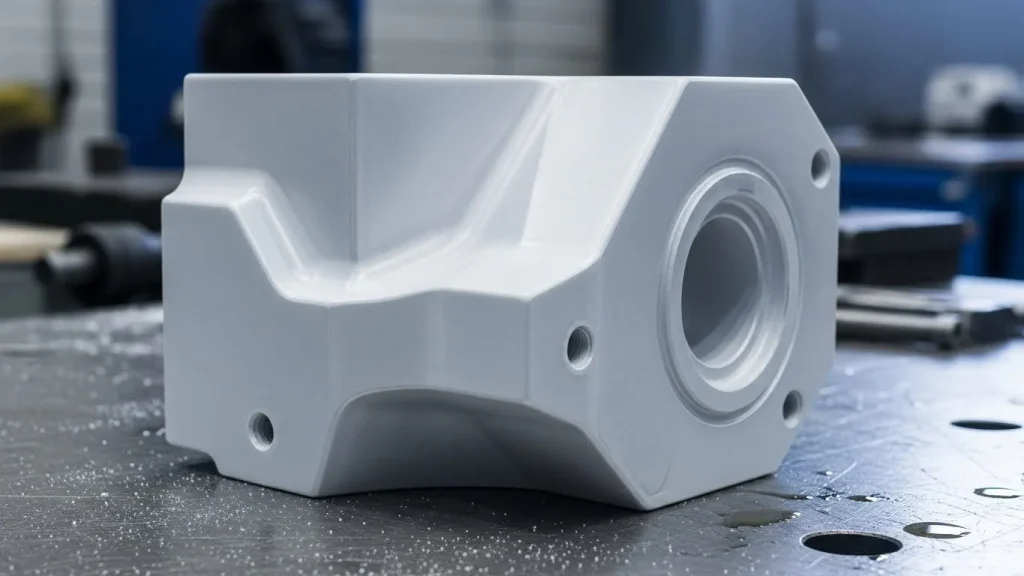

By using alumina ceramics with purity up to 99.7% Al₂O₃, UPCERA gives its Ceramic Mechanical Parts a clear technical edge. The resulting microstructure is dense and consistent, providing high hardness and excellent resistance to wear and abrasion. In practice, these parts are less likely to deform, more likely to hold tight tolerances, and better able to deliver predictable performance over the full lifetime of the equipment.

A good example is the alumina mechanical component with internal threads. Threads may look like a minor detail, but in corrosive or high-temperature zones they are often the first feature to fail. UPCERA pays particular attention to thread geometry, surface quality, and machining accuracy so that Ceramic Mechanical Parts assemble smoothly with both metal and ceramic counterparts. Stable threads help maintain clamping force and alignment while reducing the risk of leakage, vibration, or mechanical play.

Across industries, our customers tend to look for the same core properties, and UPCERA Ceramic Mechanical Parts are designed around them: high mechanical strength, strong electrical insulation, excellent heat resistance, superior corrosion and oxidation resistance, and customizable dimensions and thread forms that drop into existing designs. Because alumina ceramic is both thermally and chemically stable, these properties change slowly over time, even in equipment that starts and stops multiple times per shift.

Where Ceramic Mechanical Parts Make the Biggest Impact

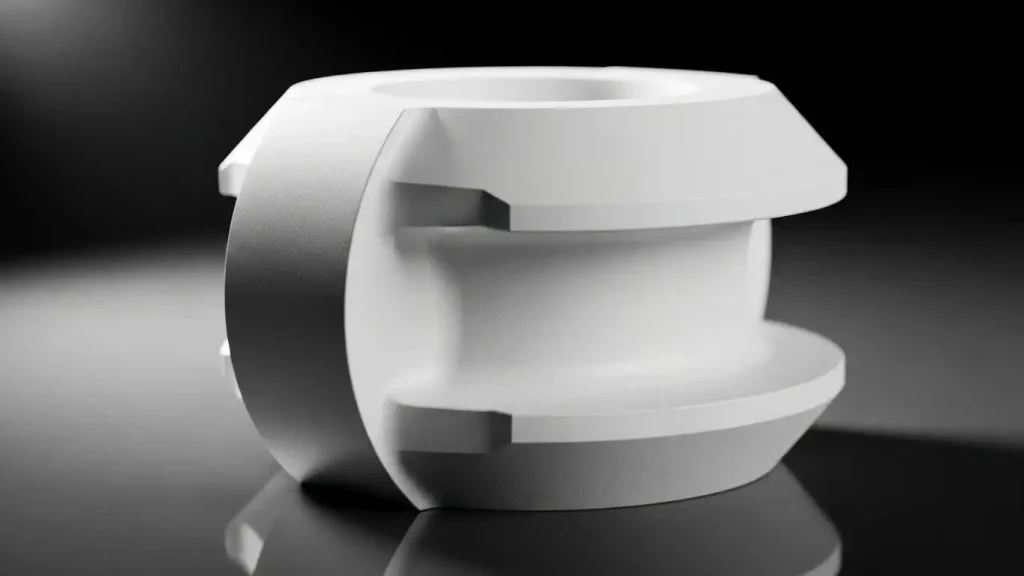

Ceramic Mechanical Parts are not limited to a single niche or product line. They can replace or complement metals wherever corrosion, temperature, or insulation are critical design constraints. In automated machinery, alumina components act as corrosion-resistant connectors, mounts, or bushings in washdown zones and fluid-handling sections. In laboratory instruments and test stands, ceramic contact parts help keep surfaces inert and clean, improving measurement reliability and reducing cross-contamination.

In electrical and electromechanical equipment, Ceramic Mechanical Parts serve as insulating supports, spacers, and feedthrough components around high-voltage circuits and sensitive sensors. Their combination of dielectric strength and rigid mechanical support helps protect both people and hardware. In high-temperature fixtures, carriers, and furnace hardware, alumina ceramics hold components or samples in place without warping or reacting with the atmosphere. In chemical and semiconductor tools, corrosion-resistant threaded fittings and structural parts made from alumina can significantly extend maintenance intervals and tool life while stabilizing critical process parameters.

Many customers first approach UPCERA because of a single chronic failure: a fitting that leaks too often, a threaded insert that seizes after a few maintenance cycles, or an insulating part that cannot withstand combined chemical and thermal load. After that problem position is replaced with a Ceramic Mechanical Part and runs reliably, it becomes natural to examine other locations where ceramics can bring similar benefits. Over time, this gradual shift can reduce emergency work, smooth out production, and lower the overall cost of running complex equipment.

Working with UPCERA on Your Next Design

If you are designing new systems or upgrading existing lines for chemical, laboratory, automation, or high-temperature use, it may be time to reconsider how many metal parts you rely on in critical zones. By introducing Ceramic Mechanical Parts early in the design process, you can build in longer maintenance intervals, greater process stability, and improved safety from the start.

UPCERA works with customers from concept through to long-term supply. Share your operating conditions, design targets, and known pain points with our technical team, and we will help you select and configure Ceramic Mechanical Parts that are genuinely prepared for corrosive and demanding environments.

- PREV: How Alumina Ceramic Stepped Ring Improves Equipment Lifespan?

- NEXT: Null

English

English 中文

中文