How a Ceramic Part Supplier Delivers High-Performance Custom Components

A Ceramic Part Supplier is more than a factory making small white parts. It is a quiet partner behind fast networks, stable medical devices, and reliable high-end equipment. From tiny sleeves in fiber connectors to custom rods and tubes in harsh environments, these components decide whether systems run smoothly or suddenly fail. So how does a Ceramic Part Supplier turn fragile-looking ceramics into high-performance custom components that survive heat, pressure, and wear?

UPCERA began the journey in 2003 with a clear focus: advanced ceramics and serious quality control. Early on, UPCERA became the first company in China to independently develop zirconia ceramic sleeves for optical communication. That step set the tone for everything that followed. Today, our products support customers in more than 100 countries and regions, but our core promise has stayed simple and consistent: stable performance, accurate dimensions, and long service life for every single part.

From Optical Communication Roots to Global Ceramic Part Supplier

UPCERA did not start by trying to serve every industry at once. Our roots are in optical communication, where small details make or break an entire network. Zirconia ceramic sleeves and ferrules produced by UPCERA were designed to sit at the very heart of fiber optic connectors, optical modules, computing power centers, and data centers.

Engineers in these fields face very clear pain points:

✅Tight control of insertion loss over years of operation

✅Precise fiber core alignment to keep signals clean

✅Components that survive constant plugging, unplugging, and temperature swings

A trusted Ceramic Part Supplier has to solve all of these at the same time. Our sleeves and ferrules are made with micron-level tolerances and carefully controlled surface quality. The thermal expansion behavior is tuned to work well with optical fibers, which helps reduce signal drift and unexpected failures. Over the lifetime of a system, that means fewer repairs, less downtime, and a lower total cost for our customers.

As our optical communication business grew, customers started asking for more. They were happy with the stability of our connectors and wanted to know whether UPCERA could support other ceramic parts inside their systems. That question pushed us to expand.

Since 2017, we have moved from being "only" an optical communication expert to a broader Ceramic Part Supplier serving semiconductors, aerospace, healthcare, new energy, precision machinery, chemicals, consumer electronics, and wearables. We reused our lean manufacturing experience from high-volume sleeve and ferrule production, then applied the same discipline to new shapes, materials, and structures.

How UPCERA Builds High-Performance Ceramic Components

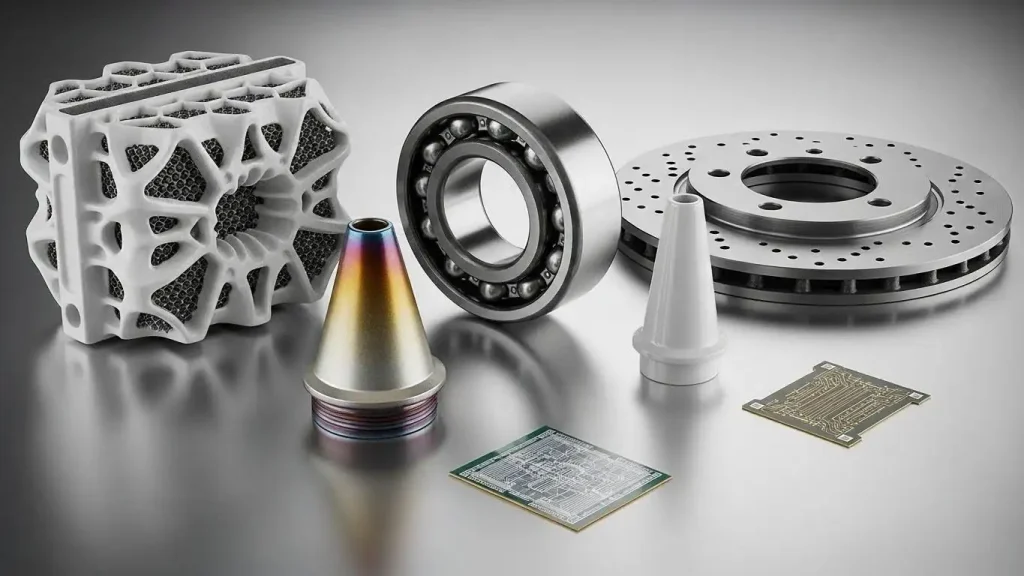

A modern Ceramic Part Supplier cannot rely on one material or one product line. At UPCERA, we work with zirconia, alumina, single-crystal alumina gemstones, silicon nitride, silicon carbide, and other advanced ceramics. Each material is selected for a specific job: high strength, insulation, wear resistance, corrosion resistance, or dimensional stability at high temperatures.

- Keeping Data and Systems Running with Sleeves, Tubes, and Ferrules

In optical networks, 5G base stations, large-scale data centers, and fiber laser platforms, failures are expensive. When a network stops, thousands of users and key processes can be affected at once. Our zirconia ceramic sleeves and ferrules play a quiet but vital role in preventing such downtime by delivering:

✅Accurate fiber alignment and low insertion loss

✅High wear resistance under continuous plug-and-play use

✅Thermal stability that maintains performance under changing conditions

Alongside connectors, tube structures have become an important area of expertise for UPCERA. In real-world use, ceramic tubes face harsh environments, from aggressive chemical media and elevated heat to rapid pressure swings and strong electric fields. We answer these challenges with zirconia, alumina, and silicon carbide tubes tailored to specific operating conditions.

Based on the end use, we fine-tune:

•Internal and external profiles and geometries

•Overall length, diameter range, and dimensional tolerances

•Special designs that improve insulation, system protection, or fluid control performance

As a result, our ceramic tubes are widely used in semiconductor manufacturing, medical technologies, energy applications, and chemical processing systems. By resisting wear and corrosion and by providing stable insulation, they help extend equipment life and reduce maintenance frequency.

- Rods and Custom Structures for Harsh Environments

Outside of communication and fluid systems, many engineers struggle with moving or structural parts that simply do not last long enough. Metal deforms or corrodes, polymers creep or crack, and standard components cannot keep up with tighter precision demands.

Here, a specialized Ceramic Part Supplier can bring a different toolbox. UPCERA produces zirconia, alumina, and silicon carbide rods in multiple formats: solid and hollow rods, stepped rods, threaded designs, plungers, pins, and locating elements. Typical applications include bearings, seals, probes, and insulation supports in precision machinery, semiconductor tools, and medical devices.

For more complex requirements, we also design and produce custom ceramic structural parts, such as:

•Bushings and nozzles for precise, wear-resistant fluid control

•Square punched and metallized parts for electrical insulation and mounting

•Ceramic-metal bonded components where mechanical strength and insulation must coexist

•Non-standard, special-shaped parts with demanding tolerances and intricate geometries

All of this is supported by a full industry chain. As a wholly-owned subsidiary of Sinocera, UPCERA benefits from in-house powder development, blank preparation, precision machining, and final inspection. That vertical integration gives us better control over stability, traceability, and long-term innovation.

Why Work with a Ceramic Part Supplier Like UPCERA

Choosing a Ceramic Part Supplier is a strategic decision. It touches your product roadmap, your maintenance schedule, and even your brand reputation. You are not just buying parts; you are choosing how your equipment will perform over years of operation.

At UPCERA, we treat customer projects as long-term partnerships rather than one-time orders. Our R&D team comes from a strong ceramics background, with experience in developing many categories of ceramic materials and a wide range of product types. That expertise lets us:

•Match materials to real operating conditions instead of using "one-size-fits-all" solutions

•Adjust formulas or process parameters when a customer's environment changes

•Support both standard parts and unique, deeply customized projects

When you collaborate with us, you can expect practical, engineering-focused support:

✅Early-stage input on design and material selection

✅Advice based on real cases from semiconductors, aerospace, medical, and other fields

✅Stable mass production capacity and consistent quality across batches

✅Flexible response when you need design changes or new variants

Whether you are designing a new optical transceiver, optimizing a semiconductor process chamber, or improving the reliability of a medical or energy system, UPCERA can help turn those requirements into robust ceramic solutions.

Call to Action

If you are currently evaluating suppliers or exploring ceramics for a new project, consider working with a Ceramic Part Supplier that understands both materials and applications. Share your drawings, target specifications, or pain points with UPCERA, and our team will help you explore the most suitable ceramic options and structures. Together, we can turn advanced ceramics into a steady, long-term advantage for your products and your customers.

English

English 中文

中文