UPCERA Innovates with Sustainable Solutions as a Ceramic Parts Manufacturer

UPCERA is gaining attention as a forward-thinking ceramic parts manufacturer in China. Known for its precision and reliability, UPCERA has long served industries like electronics, medical, and automotive. But now, the company is stepping into a new spotlight — one shaped by innovation and sustainability.

In today's world, manufacturers must do more than just deliver quality. They need to think ahead, reduce waste, and design for the future. UPCERA seems to understand this shift better than most. From smarter production methods to eco-friendly materials, the company is making bold moves.

What exactly is UPCERA doing differently? And how is it reshaping the way ceramic parts are made and used? Let's take a closer look at the changes driving this transformation.

Introduction: Leading the Future of Ceramics

UPCERA: A Trusted Ceramic Parts Manufacturer

At UPCERA, we are proud to be a leading ceramic parts manufacturer in China. For more than two decades, we have focused on producing high-quality ceramic components for various industries. Our goal has always been to deliver reliable, precise, and high-performing products.

The Demand for Sustainability in Precision Ceramics

Today, the world is changing. More companies are seeking sustainable solutions in every part of their supply chain. As a ceramic parts manufacturer, we understand the importance of eco-friendly materials and responsible production methods. Customers now expect both performance and sustainability from their suppliers.

A New Era of Innovation Begins

To meet these expectations, we are innovating. From product design to manufacturing, we are rethinking every step. This marks a new chapter not just for UPCERA, but for the entire ceramic parts industry. In the sections ahead, we'll show how we lead with quality, care, and a clear vision for the future.

Company Overview: Built on Experience, Driven by Innovation

Over 20 Years of Ceramic Expertise

Founded in 2003, UPCERA was the first company in China to develop zirconia ceramic sleeves independently. Since then, we've grown into a globally recognized ceramic parts manufacturer. With over 20 years of experience, we understand the importance of precision and quality.

Factory-Direct Supply & Global Reach

We manage everything from raw materials to final products. Our direct factory model ensures fast response times and consistent quality. Today, our products are sold in more than 100 countries. We support industries like optical communication, medical equipment, and semiconductors.

From Local Pioneer to Global Partner

We started as a local pioneer. Now, we are a trusted partner to leading tech companies around the world. Our success comes from combining technical expertise with a strong commitment to customer satisfaction. As a forward-thinking ceramic parts manufacturer, we continue to explore new opportunities and challenges across industries.

Sustainable Manufacturing: Green from the Ground Up

Eco-Friendly Materials & Processes

We believe a modern ceramic parts manufacturer must care about the planet. That's why we choose environmentally friendly materials and work to reduce waste during production. Our processes are designed to save energy while maintaining top performance.

Lean Manufacturing with Minimal Waste

Using lean manufacturing, we improve efficiency and reduce material waste. Every step in our process is carefully monitored. This helps us deliver high-quality products with minimal impact on the environment.

Aligning with Global Environmental Standards

We follow strict international standards, including ISO 14001 and RoHS. These certifications show our commitment to health, safety, and environmental responsibility. As a responsible ceramic parts manufacturer, we are proud to help our customers meet their sustainability goals too.

Signature Product I: High-Precision Ceramic Sleeves

Role in Optical Communication

As a professional ceramic parts manufacturer, we specialize in producing high-precision ceramic sleeves. These sleeves are key components in fiber optic connectors. We offer a wide range, including SC-type, LC-type, and customized designs to meet different needs.

Used in 5G, Data Centers, and Laser Equipment

Our ceramic sleeves are widely used in high-demand environments. They support 5G base stations, large-scale data centers, fiber laser systems, and computing power hubs. These industries need strong and stable connections. Our sleeves ensure reliable optical performance in critical systems.

Advantages: Accuracy, Durability, and Scalability

Each ceramic sleeve is produced with extreme precision. We use advanced manufacturing methods to reach tight tolerances. This allows for excellent alignment in fiber connections. The sleeves are also highly durable and resistant to wear. As a ceramic parts manufacturer, we provide stable monthly output of over 100 million pieces to ensure global supply needs are met.

Signature Product II: Ceramic Ferrules For 5G & Beyond

Key Component in Optical Connectors

Ceramic ferrules are one of our core products. These parts are essential in optical fiber connectors and adapters. We produce ferrules with various inner diameters, including SC, LC, and custom large-bore types.

Micron-Level Tolerance, Custom Shapes Available

We use high-purity zirconia to create ferrules with precise dimensions. Our ferrules meet micron-level tolerance standards. We also support custom ferrules for special applications. As a ceramic parts manufacturer, we offer added services like end-face polishing and laser marking for better performance and traceability.

Applications in FTTx, Data Centers, Testing Equipment

Ceramic ferrules are used in many areas, such as FTTx deployments, fiber optic testing systems, and next-generation networks. Our ferrules help ensure fast data transmission and low signal loss. This makes them ideal for 5G infrastructure and high-end electronics.

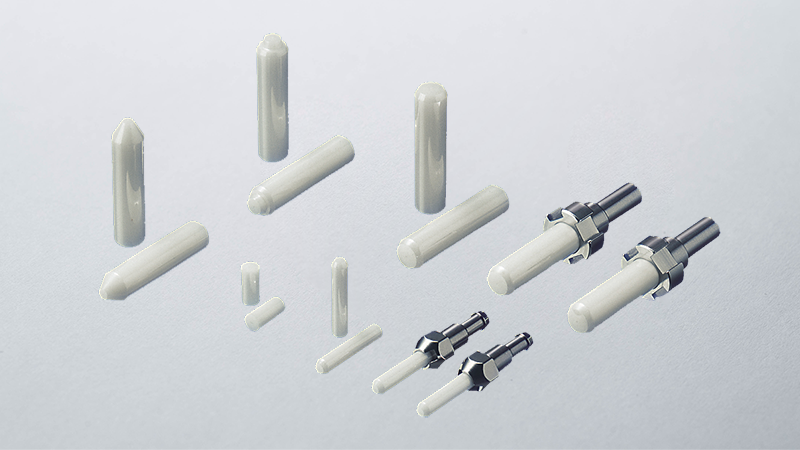

Signature Product III: Advanced Ceramic Rods And Gemstone Series

Multiple Materials for High-Performance Use

We produce ceramic rods from materials like zirconia, alumina, silicon nitride, and silicon carbide. We also offer ruby and sapphire components made from single-crystal alumina. As a trusted ceramic parts manufacturer, we select materials based on the customer's performance needs.

Applications in Machinery, Medical, Semiconductors

Our rods are used in many industries. These include precision machinery, semiconductor manufacturing, medical devices, and chemical processing. The rods offer high hardness, strong wear resistance, and excellent thermal stability.

Custom Rods, Pins, and Transparent Gemstones

We offer solid rods, hollow rods, locating pins, stepped rods, and more. For high-end optical or sensor use, our gemstone series delivers transparency and durability. Each part is made with care to ensure a smooth surface finish and precise measurements. We support full customization to fit unique technical requirements.

Customized Ceramic Components: Tailored To Every Industry

Structural Parts For Aerospace, Electronics, And Healthcare

As an experienced ceramic parts manufacturer, we know that every industry has different needs. That's why we offer a wide range of structural ceramic parts. Our products are used in aerospace, electronics, medical devices, and other high-tech fields. Each part is built to perform in demanding environments.

Complex Geometry, Metallized Interfaces, Hybrid Materials

We specialize in making parts with complex shapes and tight tolerances. Our team can handle difficult designs, including square holes, curved surfaces, and threaded ends. We also offer metallized ceramics and multi-material combinations. These parts are ideal for electrical insulation, thermal control, and high-strength support.

From Design To Delivery: Full-Service Customization

We support customers at every stage — from concept to production. As a full-service ceramic parts manufacturer, we help choose materials, refine designs, and deliver finished parts with stable quality. Our advanced molding and sintering methods ensure high precision and consistent performance.

Future Vision: Global Growth And Sustainable Excellence

Integration With Sinocera Group (Full Industry Chain)

In 2018, we became part of the Sinocera Group. This helps us manage the full supply chain — from ceramic powders to finished products. As a stronger ceramic parts manufacturer, we now offer better control, faster delivery, and greater innovation.

Global Distribution In 100+ Countries

Our products are now used in more than 100 countries and regions. We support the growth of high-end manufacturing worldwide. Whether it's for 5G, aerospace, or medical innovation, we provide ceramic solutions that make a difference.

Final Words: Commitment To Sustainable Innovation And Precision Engineering

Looking ahead, we remain focused on innovation. As a global ceramic parts manufacturer, we will continue to improve our technology, reduce our impact, and deliver value to every customer — one ceramic part at a time.

In This Article

- 1 Introduction: Leading the Future of Ceramics

- 2 Company Overview: Built on Experience, Driven by Innovation

- 3 Sustainable Manufacturing: Green from the Ground Up

- 4 Signature Product I: High-Precision Ceramic Sleeves

- 5 Signature Product II: Ceramic Ferrules For 5G & Beyond

- 6 Signature Product III: Advanced Ceramic Rods And Gemstone Series

- 7 Customized Ceramic Components: Tailored To Every Industry

- 8 Future Vision: Global Growth And Sustainable Excellence

English

English 中文

中文