Ceramic Rods Manufacturer USA: The Ultimate Sourcing Guide

Sourcing ceramic rods in the USA is a strategic decision for high-technology industries. When an application in aerospace, defense, or medical science demands absolute precision, material traceability, and zero compliance risk, procurement managers and engineers turn to domestic manufacturers. These are not simple parts; they are advanced technical components engineered to perform where metals and plastics fail.

This guide is for anyone who needs to source these critical parts. We will explore the "USA Advantage," from ITAR compliance to rapid prototyping. We will cover the key materials you must choose from. Most importantly, we will provide a step-by-step framework for how to find and vet a US-based ceramic rods manufacturer that can become a true engineering partner.

The "USA Advantage": Why Source Ceramic Rods Domestically?

Choosing a US manufacturer is not just about a "Made in the USA" stamp. It is a risk-management and quality-control strategy. For high-stakes applications, the supply chain is as critical as the component itself.

Why source ceramic rods from USA manufacturers?

Sourcing ceramic rods in the USA provides critical advantages for high-tech industries. These include guaranteed ITAR and DFARS compliance for defense, strict FDA material traceability for medical devices, and high-purity materials for semiconductors. It also allows for rapid prototyping and faster, more reliable domestic supply chains.

1. ITAR and Defense Compliance (AS9100)

For aerospace and defense contractors, this is non-negotiable.

- ITAR (International Traffic in Arms Regulations): If your ceramic rod is part of a defense assembly (like a missile, sensor, or military aircraft), it falls under ITAR. Sourcing from a non-US supplier can be a complex, and sometimes illegal, process.

- AS9100 Certification: This is the aerospace-specific quality management system. US-based manufacturers serving this industry are often AS9100 certified, ensuring a level of rigor and documentation that is a global benchmark.

2. Medical and Biocompatibility (FDA Traceability)

The medical device industry runs on traceability.

- Material Purity: A rod used in a surgical tool or as a medical implant must be made from a proven, biocompatible material (like Zirconia). US manufacturers provide the material certifications to prove it.

- FDA Compliance: A US-based supplier understands the stringent requirements of the FDA. They can provide the documentation for your 510(k) or PMA submissions, proving the material is safe and traceable.

3. Semiconductor Purity

The semiconductor industry is a world of parts-per-billion.

- No Contamination: A ceramic rod used inside a wafer-processing chamber cannot "outgas" or shed particles. US manufacturers specializing in semiconductor-grade Alumina or Silicon Carbide understand these extreme purity requirements.

4. Rapid Prototyping and R&D

A US-based manufacturer is in your time zone.

- Speed: You can get prototypes in weeks, not months.

- Collaboration: You can speak directly with the engineers who are machining your part. This ability to iterate quickly is a massive competitive advantage for R&D.

5. Quality Control and Material Traceability

A US supplier provides a verifiable paper trail. You know the rod's material is from a reputable source. You know it was fired in a certified kiln. You know it was ground on a calibrated machine. This level of trust is the core of the "USA Advantage."

What Is an Industrial Ceramic Rod?

Before we vet suppliers, let's define the component. An industrial ceramic rod is a solid cylindrical component made from an advanced technical ceramic. It is designed to leverage the unique properties of these materials.

To learn about all types, our complete guide to ceramic rods is an excellent starting point.

Where metals are ductile, conductive, and corrosive, ceramics are the opposite.

- Extreme Hardness: Many ceramic rods are harder than steel and can only be cut with diamond. This gives them incredible wear and abrasion resistance.

- High-Temperature Stability: While metals soften and melt, ceramics (like Alumina) can remain strong at temperatures over 1500°C (2700°F).

- Electrical Insulation: Most ceramics are some of the best electrical insulators on earth. This makes them essential for high-voltage applications.

- Chemical Inertness: Ceramics do not rust or corrode. They are almost completely inert to strong acids, bases, and chemicals.

- Dimensional Stability: A ceramic rod does not warp, bend, or "creep" under load over time.

These properties make them the ultimate problem-solvers for extreme environments.

The Material Makes the Rod: A Guide for Engineers

When you contact a manufacturer, their first question will be, "What material?" Your choice depends entirely on the problem you are trying to solve. The vast majority of high strength ceramic rods are made from one of these three materials.

1. Alumina (Aluminum Oxide, Al2O3)

This is the most common, cost-effective, and versatile advanced ceramic. It is the "workhorse" of the industry. It is specified by its purity (e.g., 95%, 99.5%, 99.8%).

- Key Properties:

- Excellent high-temperature stability (up to 1700°C).

- Fantastic electrical insulator.

- Very high compressive strength and hardness.

- Main Weakness: It is brittle. It has lower fracture toughness than Zirconia.

- Best For: Furnace components, electrical insulators, high-wear parts.

- Learn More: See our guide to Alumina ceramic rods.

2. Zirconia (Zirconium Oxide, ZrO2)

Zirconia is the toughest ceramic. It is often called "ceramic steel" because it solves the brittleness problem. The most common form is Yttria-Stabilized Zirconia (Y-TZP).

- Key Properties:

- Exceptional fracture toughness. It resists cracking and chipping.

- Very high flexural strength (it resists bending).

- Biocompatible and non-reactive.

- Main Weakness: Lower temperature limit than Alumina and higher cost.

- Best For: Medical implants, pump shafts, welding pins, any high-impact application.

- Learn More: See our guide to Zirconia ceramic rods.

3. Silicon Carbide (SiC)

Silicon Carbide is a specialist material for the most extreme environments. It is one of the hardest and most durable materials available.

- Key Properties:

- Extreme hardness. It is close to diamond.

- Incredible wear and abrasion resistance.

- High thermal conductivity (it removes heat, unlike other ceramics).

- Maintains strength at very high temperatures (1400°C+).

- Main Weakness: Expensive and very difficult to machine. It is also a semiconductor, not an insulator.

- Best For: Mechanical seals, pump bearings, semiconductor equipment.

Material Comparison at a Glance

| Property | Alumina (99.5%) | Zirconia (Y-TZP) | Silicon Carbide (SiC) |

| Fracture Toughness | Low | Excellent | Fair |

| Hardness | Very High | Very High | Extreme |

| Max Temperature | Excellent | Good | Excellent |

| Electrical Insulator | Excellent | Yes | No (Semiconductor) |

| Best For | Heat & Insulation | Toughness | Wear |

How to Vet a Ceramic Rods USA Manufacturer (Your 5-Step Guide)

You have a list of potential US suppliers. How do you find a true partner? You must vet their capabilities. A "supplier" might just be a reseller. A "manufacturer" has the equipment.

How do I find a high-quality ceramic rod manufacturer?

To find a quality manufacturer, you must verify their in-house capabilities. Ask if they have their own sintering kilns and, most importantly, their own precision diamond grinding equipment (like centerless grinders). A true manufacturer can provide material data sheets, quality reports, and discuss manufacturing tolerances.

Step 1: Verify True Manufacturing (Kilns and Grinders)

This is the most important test.

- Ask them: "Do you do your own sintering in-house?"

- Ask them: "What are your in-house grinding capabilities? Do you have centerless grinders?"

A true manufacturer will be proud to discuss their equipment. A distributor or reseller will be vague. A company that cannot grind its own parts cannot control the final precision.

Step 2: Demand Material Data Sheets and Traceability

Do not accept a vague quote for an "alumina rod."

- Ask for: A technical data sheet (TDS) for the exact material they are quoting (e.g., "CoorsTek AD-998" or "Morgan Advanced Materials Sintox 99.7").

- What to check: Look at the key properties: flexural strength, fracture toughness, hardness, and thermal properties. This is your proof of quality.

Step 3: Discuss Tolerances and Surface Finish

The price of a ceramic rod is all in the finishing.

- "As-Fired" Tolerance: A rod straight from the kiln has a rough surface and loose tolerances (e.g., $\pm 1\%$ of the diameter). This is the cheapest option.

- "Ground" Tolerance: A rod that has been "centerless ground" has a smooth, precise outer diameter (OD). This is the standard for most precision parts. A good US manufacturer can hold tolerances of $\pm 0.001$ inches ($\pm 0.025\text{ mm}$) or even tighter.

Be specific about what you need. Tighter tolerances mean more machine time and higher cost.

Step 4: Check for Certifications (ISO, ITAR, AS9100)

This is a key "USA Advantage."

- ISO 9001: This is the global standard for a quality management system. It is a bare minimum.

- ITAR Registered: This is a legal requirement for any company handling defense-related components.

- AS9100 Certified: This is the "gold standard" for aerospace suppliers.

- ISO 13485: This is the quality system for medical device manufacturing.

A manufacturer's certifications tell you exactly which industries they are qualified to serve.

Step 5: Ask About Their QC Lab

How do they prove the part meets your drawing?

- Ask them: "What metrology equipment do you use for final inspection?"

- Look for: CMMs (Coordinate-Measuring Machines), profilometers (for surface finish), and laser micrometers. A supplier that invests in its QC lab is a supplier that takes precision seriously.

Key Applications for US-Made Ceramic Rods

The "Made in the USA" requirement is most common in these five high-stakes industries.

1. Aerospace and Defense

- Use Case: Sensor components, insulators for avionics, structural components in high-heat zones, and "radomes" (radar-transparent domes).

- Why USA? ITAR compliance and AS9100 quality standards are mandatory.

2. Medical and Dental

- Use Case: Medical implants (like Zirconia femoral heads), surgical tools, and dental abutments.

- Why USA? FDA traceability, biocompatible materials, and ISO 13485 quality systems.

3. Semiconductor and Electronics

- Use Case: Wafer handling arms, chamber supports, and insulators for plasma etch and deposition equipment.

- Why USA? Extreme material purity. US suppliers have the experience to prevent the micro-contamination that can destroy a batch of microchips.

4. Industrial Machinery and Manufacturing

- Use Case: Pump shafts, plungers, welding pins, and mechanical seals.

- Why USA? Often, these are for retrofitting or upgrading existing US-made machinery. Sourcing domestically ensures fit and fast delivery.

5. Research, Labs, and Universities

- Use Case: Sample holders, test fixtures, and components for experimental setups.

- Why USA? Rapid prototyping. Researchers need to test an idea, get a custom part, and iterate. A domestic manufacturer can be an R&D partner.

The Manufacturing Process: From Powder to Precision

Understanding how a rod is made helps you appreciate the skill and cost. You cannot cast or forge a ceramic rod. It must be built from the ground up.

How are ceramic rods made?

Ceramic rods start as a fine powder (like Alumina or Zirconia) mixed with a binder. This paste is then formed into a "green" rod, usually by extrusion. This soft part is then fired at extreme temperatures (over 1500°C) in a furnace. This step, "sintering," makes it incredibly hard and dense. Finally, it is precision-ground with diamond tools to the exact final diameter.

- Stage 1: Forming (Extrusion): The ceramic/binder paste is forced through a circular die to create a long, continuous "green" rod. This part is soft and can be easily cut to length.

- Stage 2: Sintering (Firing): The green rods are placed in a high-temperature kiln. The binder is slowly burned out, and the ceramic particles fuse. The rod shrinks (up to 25%) and becomes incredibly hard.

- Stage 3: Diamond Grinding: The sintered rod is hard, but its surface is rough. It is put into a "centerless grinder." This machine spins the rod between two diamond-abrasive wheels, grinding the OD to a precise, smooth, and perfectly round dimension. This is the most expensive and time-consuming step.

Beyond the Standard: The Power of Custom Ceramic Rods

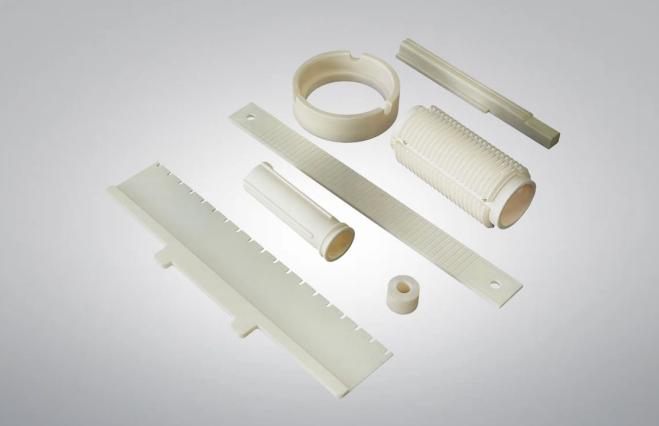

One of the greatest strengths of ceramic rods USA manufacturers is their ability to do low-volume, high-complexity custom work.

A true manufacturer is not just a "rod supplier." They are a precision machine shop. They can take a standard ground rod and add complex features.

Can ceramic rods be threaded or drilled?

Yes. A specialized manufacturer can add a wide range of custom features to a ceramic rod. This includes drilling cross-holes, grinding flats for wrenches, adding grooves for O-rings, and even grinding OD or ID threads. This custom machining is a key service offered by US-based suppliers.

Look for a manufacturer who can provide:

- Custom Ceramic Rods

- Threading and Tapping (Internal or external threads)

- Grooving (For O-rings or clips)

- Hole Drilling (Cross-holes, end-holes)

- Flats and Keys (For anti-rotation)

- Stepped Diameters (For creating complex shafts)

This custom capability is what separates a true partner from a simple distributor.

The Future: Advanced and Transparent Ceramics

The field of ceramic engineering is evolving. US-based research (often funded by defense and aerospace) is pushing the limits of what ceramics can do.

- Ceramic Matrix Composites (CMCs): These materials embed fibers (like SiC) into a ceramic matrix. The result is a "tough" ceramic that does not shatter. It fails more like a metal, making it ideal for jet engine turbine blades.

- Transparent Ceramics: As detailed on Wikipedia, materials like Alumina and Spinel can now be made optically clear. This creates "transparent armor" that is lighter and stronger than ballistic glass, as well as scratch-proof windows for high-tech sensors.

Conclusion: Your Strategic Sourcing Partner

Sourcing ceramic rods in the USA is a strategic choice. You are not just buying a part; you are buying a guarantee. You are buying ITAR compliance, FDA traceability, high-purity materials, and access to rapid, high-skill prototyping.

When you begin your search, look past the price. Ask about the process. Ask about the grinding equipment. Ask for the material data sheets. Find a partner who is a true manufacturer, and you will secure a supply chain that is as strong and reliable as the component itself.

In This Article

- 1 The "USA Advantage": Why Source Ceramic Rods Domestically?

- 2 What Is an Industrial Ceramic Rod?

- 3 The Material Makes the Rod: A Guide for Engineers

- 4 How to Vet a Ceramic Rods USA Manufacturer (Your 5-Step Guide)

- 5 Key Applications for US-Made Ceramic Rods

- 6 The Manufacturing Process: From Powder to Precision

- 7 Beyond the Standard: The Power of Custom Ceramic Rods

- 8 The Future: Advanced and Transparent Ceramics

- 9 Conclusion: Your Strategic Sourcing Partner

English

English 中文

中文