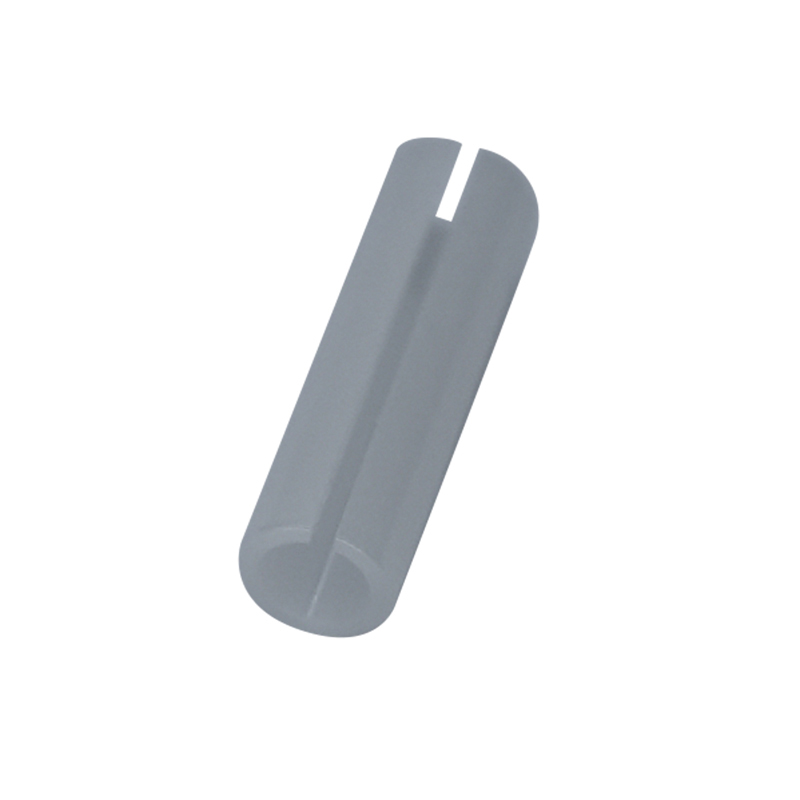

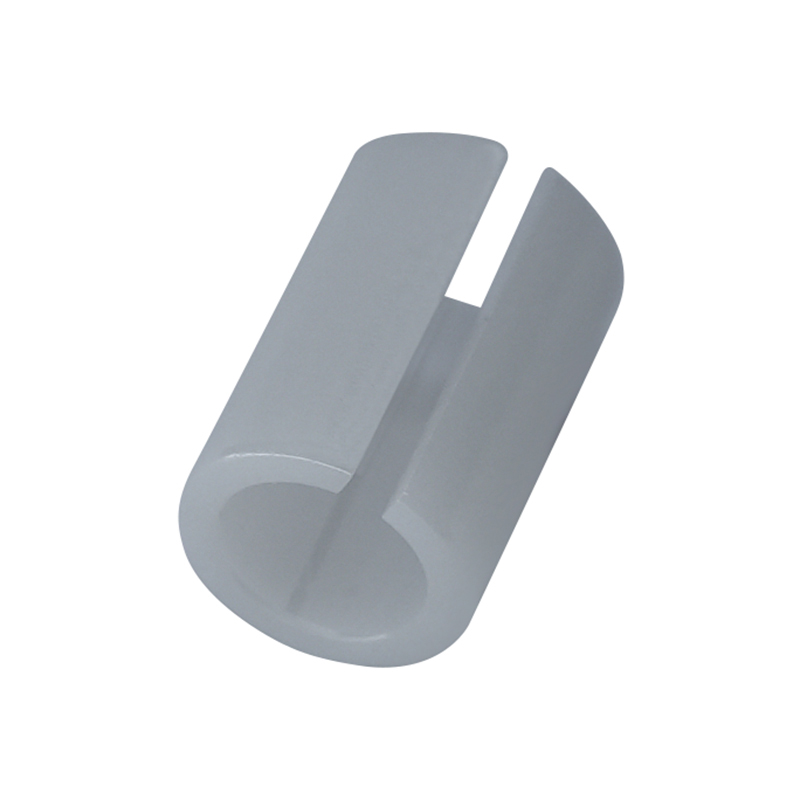

Ceramic Sleeves

As a key component in fiber optic connectors, we provide SC-type, LC-type, and various customized split and solid ceramic sleeves. With 20 years of professional expertise, we hold a leading edge in both standard and non-standard sleeve manufacturing. Our products are widely used in 5G communication, computing power centers, large-scale data centers, and fiber laser equipment.

1. 20+ years of ceramic manufacturing experience

2. Factory-direct supply with guaranteed quality

3. High precision and reliable performance

4. Custom production available

5. Stable supply with a monthly output of 100 million pieces

PRODUCTS

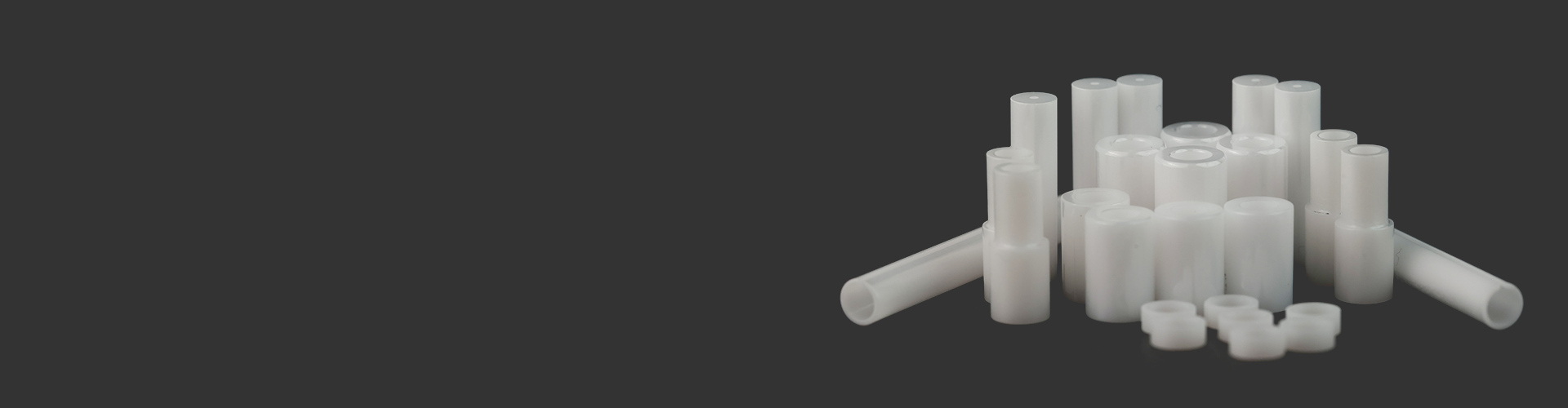

Ceramic tubes have excellent properties such as high temperature resistance, corrosion resistance, wear resistance and high strength, and are widely used in fluid transportation, temperature measurement protection, insulation support and other fields in extreme environments. We provide a variety of materials such as zirconia, alumina, silicon carbide, etc., and can choose the appropriate type of ceramic tube according to different application requirements, such as standard tubes, non-standard tubes, etc. Our ceramic tubes have high-precision processing capabilities and can be customized with different sizes, tolerances and special structures to ensure stable operation in the semiconductor, medical, energy, chemical and other industries, improve equipment life and reduce maintenance costs.

Tube structure has always been our strength at UPCERA. We have a large number of ceramic tubes of different models and sizes, and can provide you with fast delivery and competitive prices. If you are interested in a specific type of ceramic tube, please click on the specific product to view details.

Our ceramic tube production capacity range and tolerance (Unit: mm)

Performance\Material |

Alumina | Zirconia | Gemstone | Silicon Nitride |

Aluminum Nitride |

Silicon Carbide |

||||||||||||||||

| 96~99.95% | YSZ | ATZ | ZTA | Blue Zirconia | Black Zirconia | Ruby | Sapphire | |||||||||||||||

| Length Range | ≤1000 | ≤1000 | ≤1000 | ≤1000 | ≤1000 | ≤1000 | ≤100 | ≤300 | ≤200 | ≤200 | ≤200 | |||||||||||

| Outer Diameter | ≤150 | ≤250 | ≤50 | ≤50 | ≤150 | ≤150 | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | |||||||||||

Inner Diameter |

Through Hole | ≤200 | ≤200 | ≤200 | ≤200 | ≤200 | ≤200 | ≤48 | ≤48 | ≤48 | ≤48 | ≤48 | ||||||||||

| Blind Hole | ≤30 | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | ≤10 | ≤10 | ≤50 | ≤50 | ≤50 | |||||||||||

| Stepped Hole | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 | ≤10 | ≤10 | ≤50 | ≤50 | ≤50 | |||||||||||

| Minimum Wall Thickness | 0.2 | 0.1 | - | - | 0.1 | 0.1 | - | - | 0.2 | 0.2 | ||||||||||||

| Drilling | ≥φ0.4 | ≥φ0.4 | ≥φ0.4 | ≥φ0.4 | ≥φ0.4 | ≥φ0.4 | ≥φ0.4 | ≥φ0.4 | ≥φ0.4 | ≥φ0.4 | ≥φ0.4 | |||||||||||

| Thread Diameter | ≥M3 | ≥M2 | ≥M2 | ≥M3 | ≥M2 | ≥M2 | - | - | ≥M3 | ≥M3 | ≥M3 | |||||||||||

| Minimum Fillet Radius | R0.1 | R0.1 | R0.1 | R0.1 | R0.1 | R0.1 | R0.1 | R0.1 | R0.1 | R0.1 | R0.1 | |||||||||||

Outer Diameter Precision |

1-25mm: ±0.002mm 20-50mm: ±0.003mm 50-100mm: ±0.050mm 100-150mm: ±0.100mm |

|||||||||||||||||||||

Inner Diameter Precision |

0.5-3mm: ±0.001mm 3-10mm: ±0.003mm 10-30mm: ±0.005mm 30-100mm: ±0.030mm 100-150mm: ±0.050mm 150-200mm: ±0.100mm |

|||||||||||||||||||||

| Length Precision | ±0.005mm | |||||||||||||||||||||

| Roughness | Ra0.1 | Ra0.03 | Ra0.03 | Ra0.03 | Ra0.03 | Ra0.03 | Ra0.02 | Ra0.02 | Ra0.03 | Ra0.03 | Ra0.03 | |||||||||||

| Roundness | 0.002mm | |||||||||||||||||||||

| Concentricity | 0.002mm | |||||||||||||||||||||

| Straightness | 0.004mm | |||||||||||||||||||||

| Perpendicularity | 0.005mm | |||||||||||||||||||||

| Parallelism | 0.003mm | |||||||||||||||||||||

| Flatness | 0.003mm | |||||||||||||||||||||

Note: Due to the broad scope of the specifications and the correlations between different data, the above information is for reference only.

If you have any needs for ceramic tubes, don't hesitate, contact us now!

English

English 中文

中文