How Ceramic Tube Insulators Revolutionized High Voltage Safety

High-voltage safety is no longer just about bigger wires or thicker insulation. It's about smarter materials - and one of them is changing the game. The ceramic tube insulator is quietly becoming a key player in power systems, electronics, and industrial equipment. With its ability to resist extreme heat, prevent electrical leakage, and last for years without wear, this small component delivers big performance.

You'll find ceramic tube insulators in everything from circuit breakers to semiconductor machines. They don't melt, warp, or corrode like other materials. They simply do their job - silently and reliably. That's why more engineers and manufacturers are turning to ceramic for critical insulation tasks.

But what exactly makes ceramic tube insulators so special? How do they perform in harsh environments, and why are they replacing other insulating options in high-voltage systems? In this article, we'll explore the core advantages of ceramic tube insulators, their industrial applications, and the innovations driving their growth.

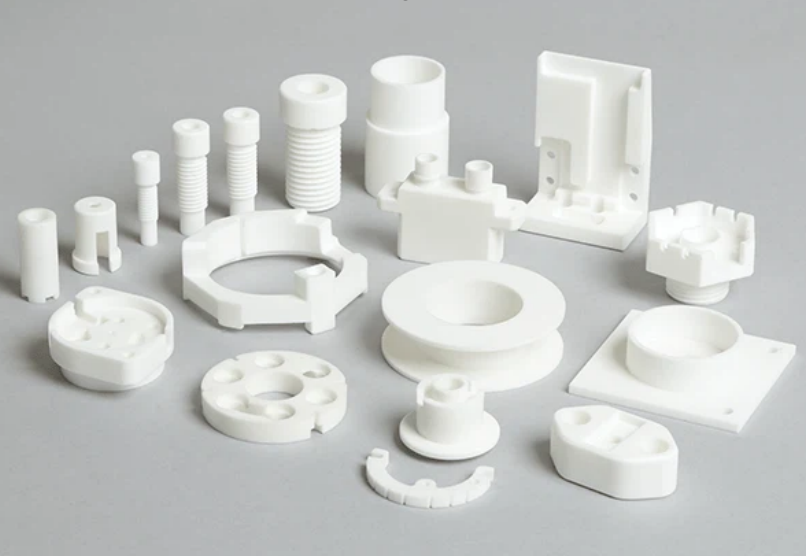

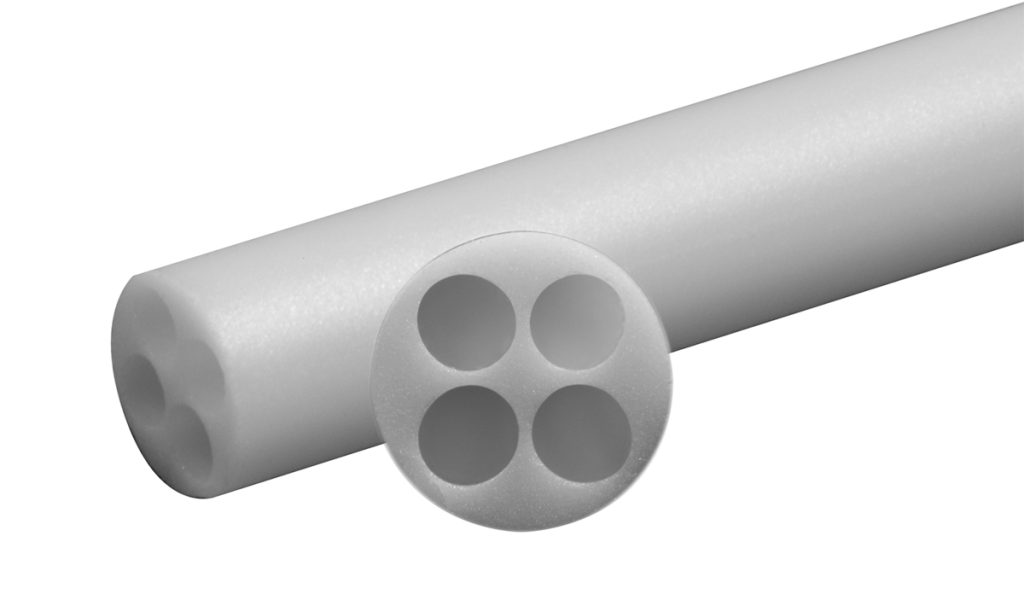

What Is a Ceramic Tube Insulator?

A ceramic tube insulator is a cylindrical insulating component made from high-purity ceramic materials, commonly alumina (Al₂O₃). Its main function is to isolate conductive elements in high-voltage or high-temperature environments.

These insulators provide:

✅ Excellent electrical insulation

✅ High mechanical strength

✅ Resistance to heat, corrosion, and chemicals

✅ Dimensional precision even under stress

Thanks to these properties, ceramic tube insulators are now widely used in power transmission, semiconductors, RF systems, medical devices, and more.

Why Alumina Is the Ideal Material for Tube Insulators

One of the main materials used in modern ceramic tube insulators is high-purity alumina, often reaching 99.9% purity. This advanced ceramic delivers outstanding performance in both mechanical and electrical applications.

• Key Advantages of Alumina Ceramic Tube Insulators

Alumina ceramic tube insulators stand out for their exceptional physical, electrical, and thermal properties. These benefits make them a preferred choice for engineers and manufacturers seeking reliability and long-term performance in challenging environments.

✅ High Dielectric Strength

Alumina acts as a robust electrical barrier, preventing conduction even under high-voltage conditions. This ensures safe operation in power systems and sensitive electronics.

✅ Thermal Stability

These insulators can withstand extreme temperatures - both high and low - without cracking or degrading. Their resistance to thermal cycling makes them ideal for continuous use in fluctuating environments.

✅ Chemical and Corrosion Resistance

Alumina ceramics maintain structural integrity in harsh industrial settings, including those exposed to acids, alkalis, moisture, or solvents.

✅ Tight Tolerances

Manufactured with extreme precision (up to ±0.01mm), they fit perfectly into complex assemblies and ensure reliable performance without mechanical or electrical failure.

✅ Low Dielectric Loss

Minimizing energy dissipation, alumina insulators are highly effective in high-frequency and RF applications, where consistent insulation and signal integrity are critical.

These key features make alumina ceramic tube insulators a durable, efficient, and safe solution for a wide range of demanding applications.

Versatile Applications Across Industries

Ceramic tube insulators offer outstanding versatility and durability, making them essential across a variety of industries. Their ability to withstand extreme temperatures, provide high dielectric strength, and resist corrosion allows them to perform reliably in both high-tech and harsh industrial settings.

• High-Voltage Electrical Equipment

Ceramic tube insulators are vital components in electrical infrastructure. They are widely used in:

✓ Transformers

✓ Capacitors

✓ Circuit breakers

These insulators prevent electrical arcing and short circuits, ensuring safety and stable performance in high-voltage applications.

• Semiconductor and Electronics Industry

In ultra-clean environments, the non-magnetic and chemically inert nature of ceramics is crucial. Ceramic tube insulators are used in:

✓ Chip fabrication systems

✓ Wafer processing equipment

They maintain electrical separation and ensure contamination-free operation in sensitive processes.

• Medical and Diagnostic Devices

Sterilizable and electrically insulating, ceramic insulators are ideal for:

✓ High-frequency imaging tools

✓ RF ablation devices

✓ Diagnostic sensors

They support precise functionality and patient safety in advanced medical technologies.

• Heating Systems and Furnaces

In high-temperature applications like industrial heaters and kilns, ceramic tube insulators provide consistent electrical isolation while resisting thermal stress and degradation, making them a reliable choice for continuous use.

The UPCERA Advantage

At UPCERA, we specialize in producing high-performance ceramic tube insulators crafted from 95% - 99.9% high-purity alumina. As a trusted ceramic manufacturer, we design, engineer, and supply precision insulators to industries around the globe.

• What Sets UPCERA Apart?

✅ Advanced Manufacturing: We maintain tight tolerances (±0.01mm) for complex geometries.

✅ Global Compliance: Our products meet RoHS, REACH, and other international standards.

✅ Application Expertise: From industrial power systems to aerospace and medical devices, we know what your project needs.

✅ Customer-Centric Design: We collaborate closely with engineers to offer custom solutions for specific insulation challenges.

We believe that insulation isn't just a component - it's a foundation for safety, stability, and long-term performance.

Meeting Global Standards for Safety and Sustainability

In an era focused on environmental responsibility and product reliability, ceramic tube insulators must comply with strict global standards.

✅ RoHS (Restriction of Hazardous Substances)

✅ REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals)

At UPCERA, we go beyond compliance by continually testing our insulators for durability, thermal shock resistance, and dielectric strength. By choosing certified ceramic insulators, manufacturers can ensure product longevity, lower maintenance costs, and greater user safety.

What Sets Ceramic Tube Insulators Apart in High-Voltage Technology?

Here's why ceramic tube insulators are redefining high-voltage safety:

✅ Superior Insulation Performance: With minimal dielectric loss, they prevent power leakage even in compact systems.

✅ Long-Term Durability: Resistant to cracks, corrosion, and thermal degradation.

✅ Environmentally Friendly: Reusable, recyclable, and compliant with global safety norms.

✅ Adaptable to Innovation: Suitable for modern applications like electric vehicles, clean energy, and smart grid technologies.

With the rise in renewable energy and compact electronics, the demand for ceramic tube insulators is only expected to grow.

Final Thoughts

The ceramic tube insulator is no longer just a passive component - it's a critical enabler of modern, high-voltage technologies. From protecting sensitive electronics to ensuring reliable operation in extreme environments, its role is both powerful and indispensable. At UPCERA, we are proud to lead this transformation. With precision engineering, global compliance, and expert service, we continue to deliver ceramic solutions that empower industries to innovate safely and sustainably.

Interested in learning more or requesting a quote?

Visit our website or contact our team - we're here to insulate your next breakthrough.

English

English 中文

中文