Ceramic Tubes for High Temperature Can Power the Next Generation of Clean Energy

In today's push for cleaner, more efficient energy, materials matter more than ever. One material stands out-ceramic tubes for high temperature use. These tubes are small but powerful. They handle extreme heat without breaking, cracking, or losing shape. That makes them ideal for the next generation of clean energy systems.

From solar power plants to hydrogen fuel production, ceramic tubes are quietly playing a key role. They improve performance, reduce energy loss, and last longer than traditional options. But how exactly do they do it? And why are top engineers and researchers focusing on this technology now? In the next section, we'll explore the real-world impact of ceramic tubes-and what they could mean for the future of energy.

Why High-Temperature Materials Matter

Clean Energy's Toughest Challenge: Operating Under Extreme Heat

In clean energy systems, heat is not just a byproduct-it's a test. Whether in solar power towers, hydrogen reactors, or energy storage systems, components must perform under constant thermal stress. Many traditional materials fail in such conditions. They warp, degrade, or corrode over time. This leads to breakdowns and costly maintenance.

The Hidden Backbone: Ceramic Tubes for High Temperature

Ceramic tubes for high temperature use are now essential. These small, tough components are often hidden inside complex equipment. But they play a big role. Their resistance to heat, corrosion, and pressure makes them ideal for extreme environments.

Why Ceramics Outperform Metals

Unlike metals, ceramics do not melt or deform easily. They maintain their structure even when exposed to very high temperatures. They also resist chemical corrosion and electrical conductivity. That's why ceramic tubes for high temperature are replacing metal tubes in many applications.

The Core Benefits of Ceramic Tubes

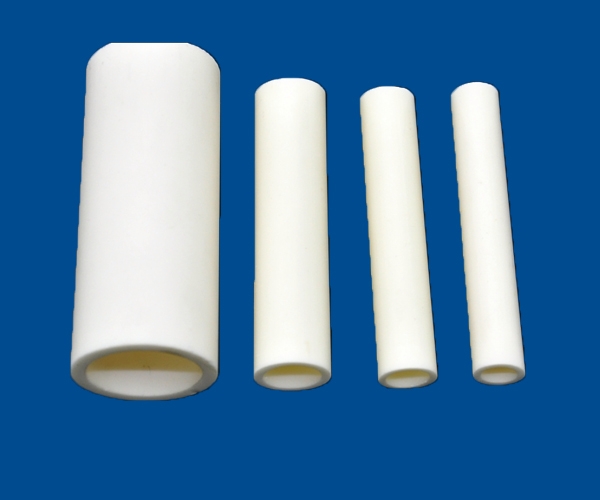

Thermal Resistance: Standing Strong Under Heat

Ceramic tubes for high temperature are designed to survive and perform in intense thermal environments. They do not expand or crack easily. This means they remain stable even when exposed to rapid heating and cooling cycles.

Chemical and Mechanical Strength: Built for Harsh Conditions

These ceramic tubes also resist acids, gases, and other corrosive chemicals. They are hard, strong, and long-lasting. In clean energy plants, where materials often face both heat and chemical exposure, ceramic tubes offer a reliable solution.

Precision and Reliability: Why Industries Are Making the Switch

Ceramic tubes can be manufactured with extremely tight tolerances. This allows for precision in installation and operation. Their long service life reduces the need for frequent replacements. That's why industries like energy, semiconductor, and medical technology prefer ceramic tubes for high temperature applications.

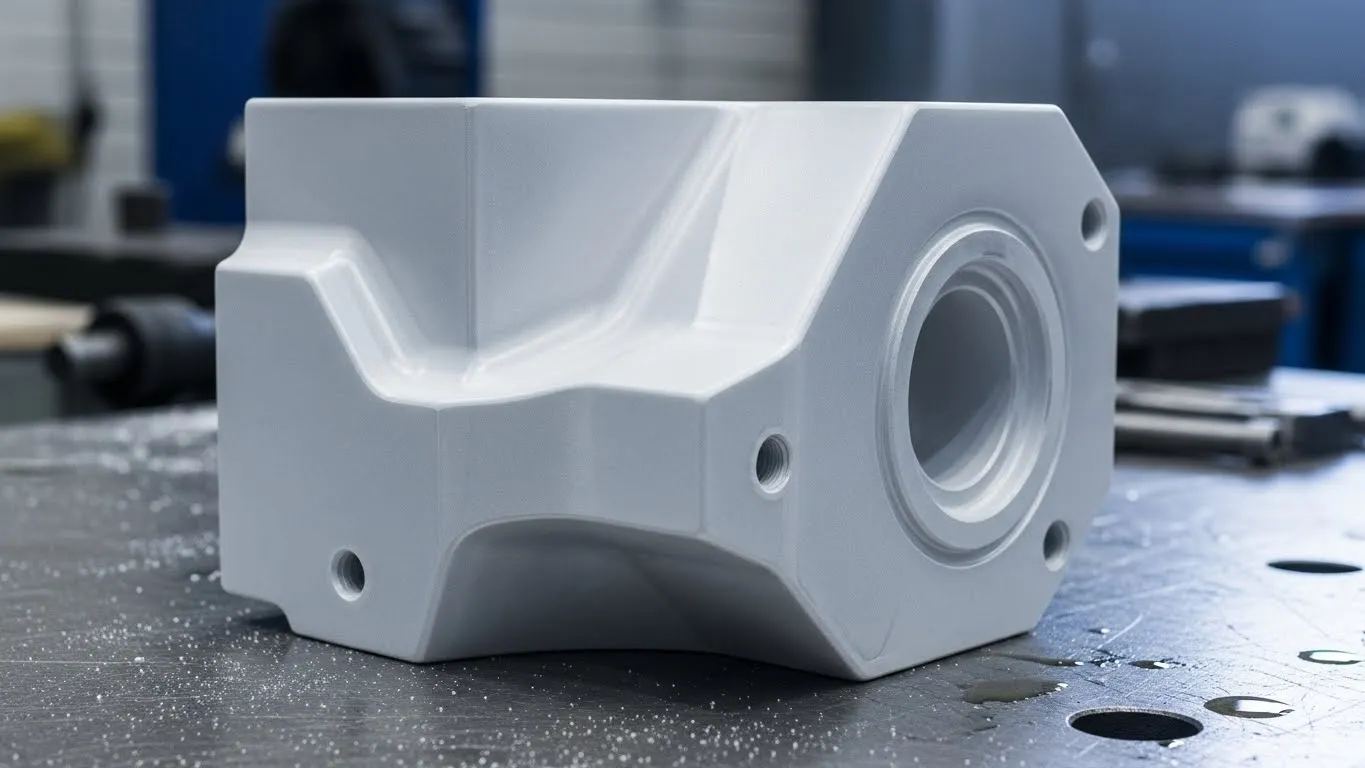

Custom Design: Meeting Specific Industry Demands

Modern clean energy systems require customized components. Standard tubes often don't fit the need. That's where custom ceramic tubes come in. They can be made in different sizes, shapes, and materials-such as zirconia, alumina, or silicon carbide-to match specific system designs.

Introducing UPCERA: Expertise in Advanced Ceramics

From Tsinghua Roots to Global Reach

We are UPCERA, a leading manufacturer of high-performance ceramic products. Our journey started with ceramic material technology developed at Tsinghua University. Since then, we've grown into a global supplier trusted by companies in optical communication, data centers, and clean energy.

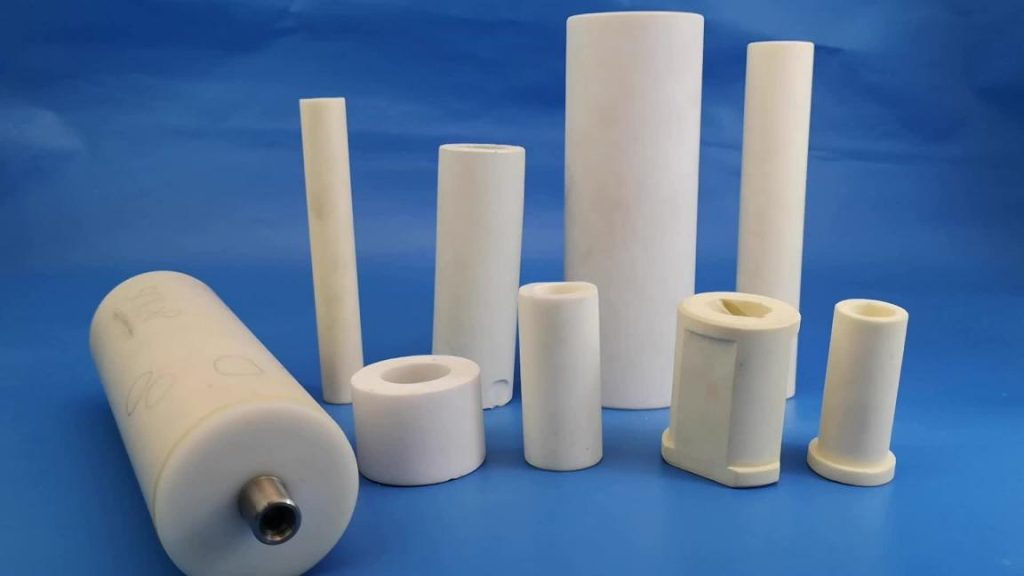

Two Decades of Innovation in Ceramic Tubes for High Temperature

For over 20 years, we've focused on developing ceramic tubes for high temperature and high-performance environments. We offer a wide range of materials, including zirconia and alumina. Our ceramic tubes are used in semiconductor machines, chemical reactors, medical devices, and energy systems.

Trusted Worldwide for Custom Ceramic Solutions

At UPCERA, we specialize in both standard and non-standard ceramic components. Our Custom Split Ceramic Sleeve is a great example. It is made from high-purity zirconia or alumina, offering wear resistance, thermal stability, and precise alignment in fiber optic and high-heat applications.

We understand that every system is different. That's why we provide full customization-outer diameter, inner diameter, length, and structural design-to meet your exact needs. Our products ensure stable, long-term performance, even in the harshest environments.

Custom Split Ceramic Sleeve

What It Is

The Custom Split Ceramic Sleeve is a high-precision component. It is mainly used in fiber optic connectors and high-temperature electronic systems. Its split design ensures accurate alignment. It also offers reliable protection in demanding conditions.

Why It Stands Out:

This product uses high-purity zirconia or alumina. These materials offer excellent thermal stability. The split structure allows for self-centering, which improves installation and stability. We offer custom dimensions to match non-standard fiber connectors. Whether for R&D projects or niche applications, this sleeve delivers reliable performance.

Use Cases: Small Part, Big Impact

The Custom Split Ceramic Sleeve is used in:

- Optical communication connectors

- High-temperature sensors

- Electronic modules in clean energy systems

Its small size does not limit its value. In fact, it plays a key role in alignment, insulation, and heat resistance.

Beyond Standard: Non-Standard Ceramic Tubes and Sleeves

Tailored for Toughness: Built for Your Conditions

Not all systems use standard parts. We understand this. That's why we design non-standard ceramic tubes for high temperature applications. These products are custom-made for challenging operating environments.

Key Features: Engineered to Endure

Our non-standard ceramic tubes offer:

- High wear and corrosion resistance for chemical exposure

- Thermal insulation and electrical isolation for safety

- Dimensional stability under thermal shock for extreme conditions

Each piece is made with precision. We work with zirconia, alumina, and other advanced materials. This allows us to match your exact needs.

Industries Benefiting: Widely Applied

These products are used in:

- Hydrogen production systems

- Semiconductor fabrication equipment

- Chemical processing lines

- Laser and precision machinery

In each case, our ceramic tubes for high temperature improve system life and reduce maintenance costs.

Ceramic Engineering In Action: Real-World Applications

Case Study: Reliable Energy Storage

In energy storage systems, temperature stability is vital. Our ceramic tubes help maintain safety and performance. They act as insulators and protective layers. This supports stable energy conversion and storage.

Ceramic Tubes in Fusion and Solar Power

Fusion reactors and solar towers reach extreme temperatures. Our ceramic tubes for high temperature are used to guide fluids, protect sensors, and insulate wires. Their strength and heat resistance make them ideal for these systems.

Precision + Durability: Fewer Failures, Less Downtime

When equipment runs non-stop, reliability matters. Our ceramic components last longer. They resist wear, heat, and corrosion. This reduces the need for repairs and replacements, saving both time and cost.

Emerging Frontiers: Supporting Clean Innovation

Our ceramic tubes are used in next-generation hydrogen systems and carbon-neutral projects. These are the technologies of tomorrow. We are proud to support them today with materials that perform under pressure.

Why Choose UPCERA for Your Ceramic Needs

Fast Customization: Quick and Flexible Service

We know your time matters. At UPCERA, we provide fast prototyping and short lead times. Whether you need one part or a full production batch, we can deliver on schedule.

Quality You Can Trust: Experience Meets Precision

We have over 20 years of experience. Our ceramic tubes for high temperature are trusted by industries around the world. We use advanced equipment and strict quality control to ensure every product meets the highest standard.

Click to Discover: Explore Our Products

From Custom Split Ceramic Sleeves to complex non-standard tubes, we offer solutions that match your exact needs. Whether you work in energy, telecom, medical, or semiconductor fields, we are ready to support your innovation.

Visit our product catalog to learn more. Let's build the future-together.

In This Article

- 1 Why High-Temperature Materials Matter

- 2 The Core Benefits of Ceramic Tubes

- 3 Introducing UPCERA: Expertise in Advanced Ceramics

- 4 Custom Split Ceramic Sleeve

- 5 Beyond Standard: Non-Standard Ceramic Tubes and Sleeves

- 6 Ceramic Engineering In Action: Real-World Applications

- 7 Why Choose UPCERA for Your Ceramic Needs

English

English 中文

中文