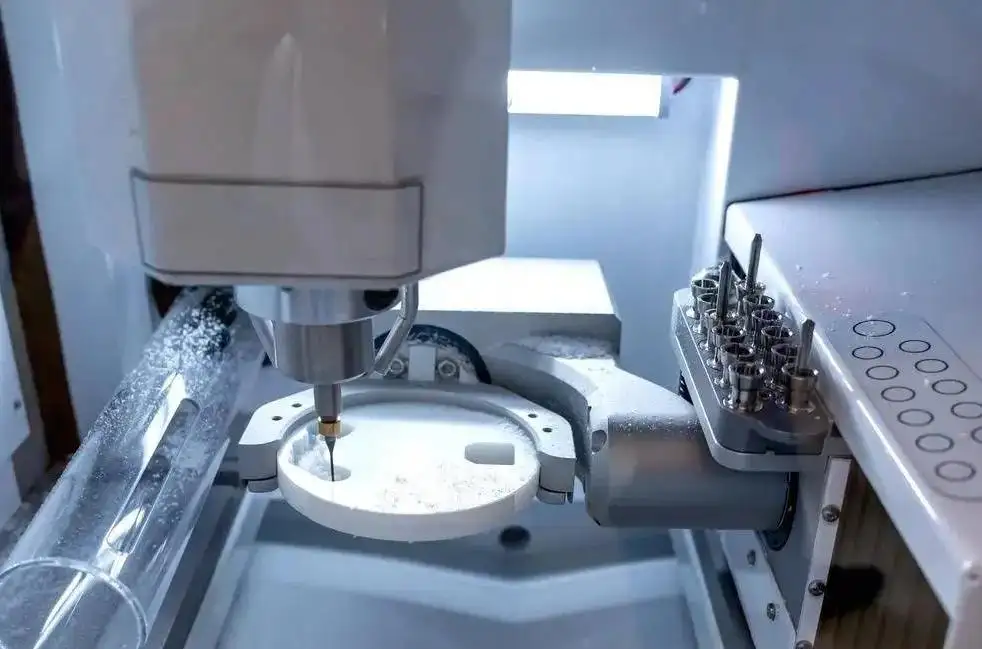

How CNC Ceramic Machining Improves Precision in Tough Materials

CNC Ceramic Machining uses computer-controlled tools to shape ultra-hard ceramics with high accuracy. It turns zirconia, alumina, silicon nitride, and silicon carbide into precise parts with clean surfaces. These parts work in optical communications, semiconductors, aerospace, medical devices, new energy, and consumer electronics. The goal is stable size, low wear, and reliable performance under heat and stress. But why does it beat metal machining on tough materials? And which steps make the biggest difference to precision? Keep reading - we'll unpack the simple methods that deliver tight tolerances without cracks, delays, or hidden costs.

From Powder To Precision: The UPCERA Way

At UPCERA, precision begins long before a tool touches a part. We start with the right ceramic for the job and then tailor the machining path to that microstructure.

Material Strategy That Fits The Application

Zirconia brings high fracture toughness and wear resistance, alumina and single-crystal alumina deliver hardness and electrical insulation, silicon nitride offers thermal shock resistance with excellent strength-to-weight, and silicon carbide thrives against abrasion and high temperatures. By matching these properties to functional needs, we avoid classic traps - overheating edges, chipping on exit, or inconsistent surfaces that won't seal or bond.

Process Control That Guards Every Micron

Our R&D roots trace to Tsinghua University's ceramics expertise. That foundation shows up in the shop: we refine feed rates, step-overs, and dwell times around crack growth thresholds; we manage coolant and thermal profiles to prevent residual stress; and we use in-process metrology to track variation before it drifts. The result is repeatable accuracy on parts that are thin-wall, micro-bore, or feature tight coaxiality.

✅ What you'll notice on your parts:

- Adaptive fixturing that tames vibration on fragile geometries

- Diamond tooling playbooks that limit edge micro-cracks

- Closed-loop measurement that keeps tolerances centered during long runs

- Thermal discipline that prevents warpage after finishing

This is not about a single "hero machine.” It's a lean, integrated flow refined through years of mass production in sleeves and ferrules - now applied to complex custom parts.

Where CNC Ceramic Machining Pays Off

Customers use UPCERA's capabilities to remove bottlenecks in critical systems: optical communication benefits from stable alignment that protects insertion loss; semiconductor lines rely on wear parts and fixtures that survive chemicals and abrasive slurries; aerospace and new-energy programs gain lighter, heat-tolerant components; healthcare and consumer electronics need clean, biocompatible, dimensionally stable features. In each case, CNC Ceramic Machining keeps dimensions tight and surfaces consistent, so assemblies go together the first time - and stay that way under stress.

Engineering Out The Headaches: From DFM To Final Inspection

If you've tried to machine hard ceramics, you've likely seen the pain: shattered tools, rework spirals, surfaces that won't polish, and tolerances that shift after thermal cycling. We design those risks out - early.

Design Support That Reduces Iterations

Bring us in during concept or early prototyping. We help pick the ceramic grade, refine wall thickness and corner radii, and set surface requirements that protect function without driving unnecessary cost. Because UPCERA controls both materials and manufacturing, we can balance toughness, polishability, dielectric behavior, and dimensional stability as a single system. Fewer redesign loops, faster validation, and a clearer path to production.

Quality You Can Trace - and Trust

Every lot runs under a strict quality management system with statistical process control. Environmental controls protect cleanliness; calibrated gauges and optical measurement verify critical dimensions; and final inspection checks surface integrity where sealing, bonding, or optical mating will occur. That's how we support mission-critical assemblies in data centers and optical modules, where a micron out of place can mean measurable signal loss.

Custom At Scale, Not Just One-Offs

Since 2017, we've broadened beyond sleeves and ferrules to custom components for semiconductors, aerospace, healthcare, new energy, mechanical engineering, chemicals, consumer electronics, and wearables. Our deep collaboration with Sinocera strengthens source-level R&D and quality control, giving you consistent material performance and robust process windows. You get the best of both worlds: the efficiency of scaled production and the flexibility of a dedicated engineering team.

✅ Typical wins our customers report:

- Tighter tolerances that hold after thermal cycling

- Longer service life under abrasive or corrosive media

- Smoother assembly thanks to consistent surface finishes

- Lower total cost from fewer rebuilds and less downtime

Ready To Build What Metals Can't?

When metals reach their limits, CNC Ceramic Machining extends the envelope - higher temperatures, tougher wear conditions, cleaner operations, and more stable dimensions over time. UPCERA's end-to-end approach - material selection, toolpath strategy, thermal and metrology control, and certified quality - shrinks your risk and accelerates launch. Whether you need zirconia alignment features for optics, silicon nitride fixtures for thermal shock, alumina insulators for high-voltage, or silicon carbide wear plates for abrasive flows, we turn the hard problems into reliable production parts.

Call To Action

Have a component that keeps failing, drifting, or shedding particles? Contact UPCERA for a fast DFM review and prototype plan. We'll recommend the best ceramic, the right CNC Ceramic Machining strategy, and inspection criteria that match your performance targets - so you can move from trial to production with confidence, cleanly and at scale.

English

English 中文

中文