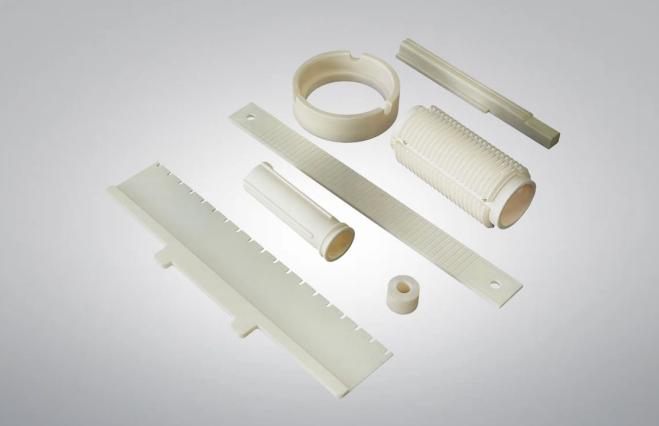

Custom Alumina Ceramics Applications in Modern Industries

Custom Alumina Ceramics keep critical equipment running where metals and polymers struggle. From the UPCERA shop floor to your production line, our goal is simple: stable quality, predictable costs, and fewer surprises in the field. In this article, we share how we tackle real plant problems, why alumina's material behavior matters, and where our components deliver measurable value across modern industries.

Why Custom Alumina Ceramics Solve Real Plant Problems

Unplanned downtime is expensive. Abrasion creeps in. Heat cycles loosen tolerances. Cleaning chemistries attack seals and seats. Each of these pain points slows output and complicates maintenance windows. At UPCERA, we build Custom Alumina Ceramics to match your assemblies, not the other way around. That means working from the constraints you live with - mounting footprints, clearances, surface finish targets, and existing torque specs - so new parts drop in without re-qualifying the whole station.

We begin with high-purity alumina (Al₂O₃) and tight process controls to achieve consistent density and dimensional stability. That stability protects stack-ups and preserves alignment over long service intervals. It also reduces the rework that follows drift in metallic or polymer parts. Our team collaborates early to adjust geometry and edge breaks, balancing wear resistance with gentle interfaces where you need them. For manufacturers rolling out common platforms across multiple sites, that consistency simplifies inventory and eases global support. The result is boring reliability - exactly what production teams want.

When legacy components fail, the pattern is familiar: soft surfaces wear, electrical isolation is not robust enough, or corrosion accelerates after chemistry changes in cleaning or etch steps. Custom Alumina Ceramics address these issues directly. Hard surfaces resist abrasion. Inert chemistry endures aggressive media. Electrical insulation supports high-voltage or RF designs without adding complex shielding. Over time, those advantages compress maintenance lists and make downtime more predictable.

Core Properties Engineers Count On in Custom Alumina Ceramics

Selecting a material is not a lab exercise; it is a reliability decision. The properties below anchor UPCERA's designs for Custom Alumina Ceramics, including long-tail needs such as alumina ceramic mechanical parts and high-purity aluminum oxide components:

- High wear resistance and long service life - Surfaces hold up under continuous motion and repetitive contact.

- Excellent mechanical strength and rigidity - Parts keep shape under load, shock, and vibration.

- Dimensional precision with tight tolerances - Advanced machining and finishing hit exact geometries.

- Corrosion and chemical resistance - Stability against acids, alkalis, and common industrial cleaners.

- Thermal stability at elevated temperatures - Strength remains steady in hot zones and during heat cycles.

- Superior electrical insulation - Reliable isolation for high-voltage paths and RF hardware.

- Cost-effective longevity - Durability stretches replacement intervals and trims total ownership costs.

What this means on your line. In operation, these traits translate to repeatable alignment during cycling, predictable friction behavior at interfaces, and safer proximity to sensitive electronics. Instead of chasing tolerance drift, your team focuses on throughput, calibration, and preventive maintenance. For procurement, longer intervals between changeouts flatten spend and reduce emergency orders.

Key Applications for Custom Alumina Ceramics

- Semiconductor Fabrication and Metrology

Particle control, purity, and geometry all matter at once. Our Custom Alumina Ceramics support wafer handling, chamber hardware, and metrology fixtures that see frequent cleaning and thermal cycling. The combination of hardness, chemical inertia, and stable dimensions helps reduce contamination risk while keeping position repeatable. For engineers tuning uptime, fewer wear-related adjustments free capacity for process improvement.

- Medical and Dental Devices

Clinicians need tools and components that survive sterilization without shifting dimensions. Alumina's rigidity, smooth surfaces, and resistance to cleaning agents make it a practical choice for surgical instruments and select implant-adjacent parts. With Custom Alumina Ceramics, OEMs gain cleanability and consistent fit, two traits that improve device reliability and simplify validation.

- Automotive and Aerospace Systems

Under-hood temperatures, vibration, and corrosive condensates punish conventional parts. Alumina preserves clearances in actuators and thermal barriers while offering robust electrical insulation around power electronics. Manufacturers use Custom Alumina Ceramics where access is limited and downtime is costly, improving service life without adding complexity to existing assemblies.

- Industrial Machinery and Automation

Guides, bushings, rollers, and nozzles need to hold geometry despite abrasion and load. Metals can gall; polymers can deform. Alumina stays hard and dimensionally stable, which keeps indexing accurate and motion smooth. UPCERA tunes surface finish, radii, and mounting features so components seat correctly and run-in is short. Predictable wear behavior lets maintenance teams set sensible intervals and stick to them.

- Electrical, Electronics, and Chemical Processing

As an insulator, alumina is a natural fit for substrates, spacers, and shields in high-voltage and RF designs. In chemical plants, its corrosion resistance supports valves, seals, and contact parts exposed to aggressive media. With Custom Alumina Ceramics, operators protect assets without exotic alloys or frequent replacements. For project engineers, that means less redesign when process chemistry changes.

How we work at UPCERA. Every engagement starts with the application and the drawing. We review tolerance stack-ups, identify risk points, and suggest practical geometry or finish adjustments. If an edge will see repeated impact, we propose a radius that protects both the ceramic and its mating part. If a surface must stay clean in a particle-sensitive zone, we target finishes that are smooth yet manufacturable. Our process aligns material preparation, forming, sintering, and machining with the way your team assembles, cleans, and measures. The goal is not a catalog part - it is a reliable component that fits your line today and scales with you tomorrow.

CTA - Put alumina to work on your line. If you are troubleshooting wear, heat, or chemical attack - or you need dependable electrical isolation with tight tolerances - talk to UPCERA. Request a quick DFM review, sample parts, or a pilot build. We will show how Custom Alumina Ceramics can stabilize your process, stretch maintenance intervals, and deliver the kind of boring reliability that keeps production on schedule.

English

English 中文

中文