What Advantages Do Custom Ceramic Insulators Offer Engineers?

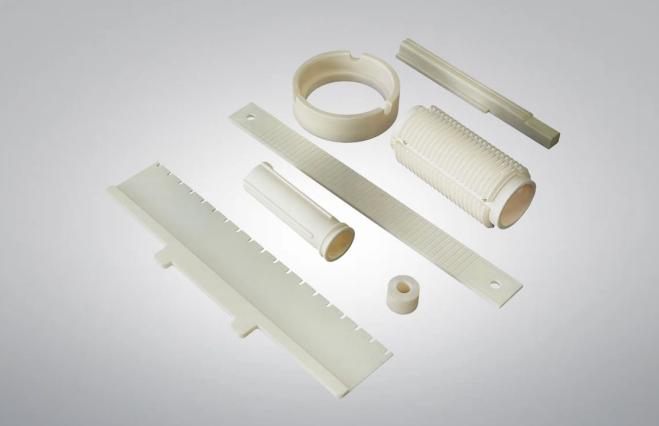

What advantages do Custom Ceramic Insulators really offer engineers? At first glance, they look like simple white parts. In fact, they are carefully engineered components made from high-purity ceramic, designed to isolate electricity and withstand heat, stress, and harsh environments. You will find them hiding inside power equipment, sensors, heaters, and precision instruments. They keep signals clean, circuits safe, and systems stable. Yet many teams still rely on standard, one-size-fits-all solutions. So what changes when you switch to custom designs - and why are more engineers making that move now?

What Advantages Do Custom Ceramic Insulators Offer Engineers?

At UPCERA, we spend a lot of time talking with design, process, and reliability engineers. The story we hear again and again is similar: a project starts with standard catalog insulators, everything seems fine in early tests, and then problems appear when power, temperature, or operating hours go up.

Insulators start to crack during assembly. Clearances are not quite right. A part that worked in the lab fails after a few months on the production line. And suddenly, that "simple" component becomes a key source of downtime and redesign cost.

This is where Custom Ceramic Insulators made from high-purity alumina earn their place. Instead of forcing your design to fit around generic parts, you define exactly what you need, and we build the insulator to match those requirements.

From Weak Link to Trusted Component

For most projects, the question is not "Can I find an insulator?" You can always find something in a catalog. The real question is:

Can I rely on this insulator to perform for years in a demanding environment?

- Tackling Real Engineering Pain Points

In practice, engineers come to us when they are dealing with issues like:

✅Breakdown or tracking at higher voltages than originally planned

✅Drift, warping, or softening when equipment runs hot for long periods

✅Micro-cracks appearing after repeated thermal cycling

✅Insulators that don't match complex layouts, leading to awkward workarounds

✅Extra work during RoHS, REACH, or customer environmental audits

By switching to Custom Ceramic Insulators, these problems are no longer "surprises" that show up late in validation. They become design parameters that we can engineer and control together.

- Why High-Purity Alumina Makes a Difference?

Alumina is widely known as a strong electrical insulator, but in real projects its advantages go beyond textbook properties:

•High dielectric strength helps you maintain safe distances and clearances even as voltage levels rise.

•Low dielectric loss supports RF, sensing, and high-frequency electronics where signal stability matters.

•Thermal stability means the part keeps its shape and performance even near heating elements, in furnace zones, or inside compact power modules.

Unlike many polymer insulators, alumina does not soften when exposed to elevated temperatures. It stays rigid, dimensionally stable, and electrically reliable, even under continuous operation.

- Built to Survive Harsh Environments

Most failures don't happen in the clean lab. They happen on the factory floor, in outdoor switchgear, or inside systems that are regularly cycled on and off.

High-purity alumina ceramics from UPCERA offer:

✅Resistance to thermal shock from frequent heating and cooling

✅Strong performance in corrosive or humid atmospheres

✅High mechanical strength and hardness to handle vibration and assembly stress

This is why Custom Ceramic Insulators are common in power transmission, industrial heaters and furnaces, vacuum and semiconductor equipment, automotive and aerospace electronics, and medical devices where both cleanliness and reliability are core requirements.

What Sets UPCERA's Custom Ceramic Insulators Apart?

When we say "custom," we do not simply mean a different length or diameter. For UPCERA, customization starts with understanding the full picture: your electrical requirements, mechanical interfaces, process environment, and manufacturing constraints.

- Material and Geometry Designed around Your System

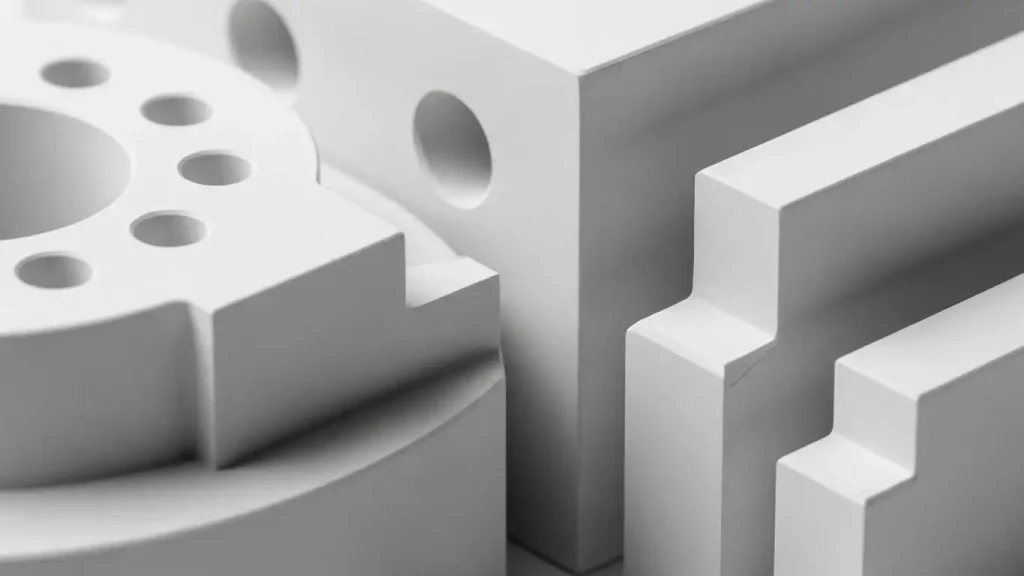

Our Custom Ceramic Insulators are produced from 99% alumina, giving a combination of:

•Excellent electrical insulation

•Strong heat resistance

•Stable behavior under high voltage and high temperature

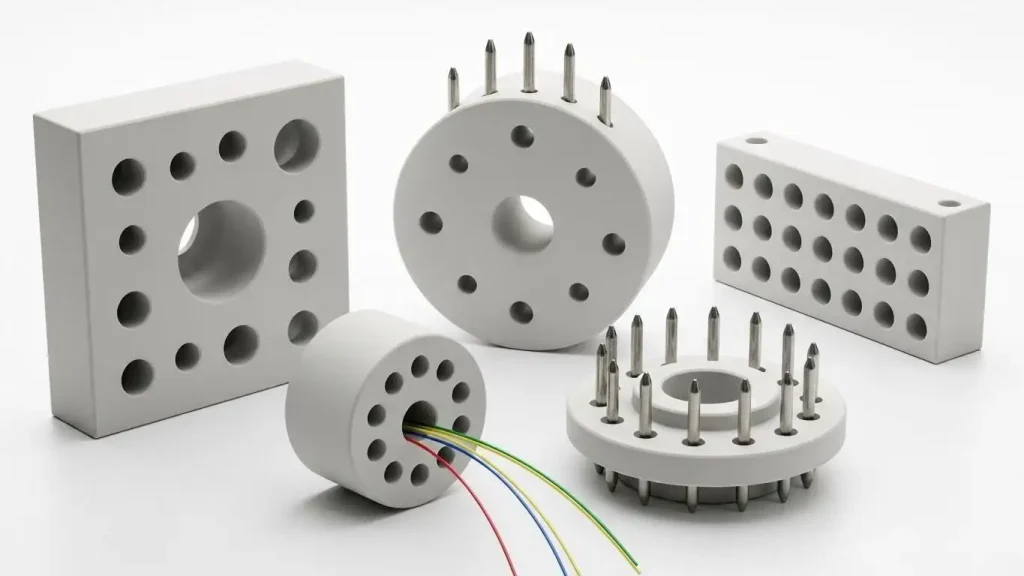

We often work with multi-hole or complex internal geometries. These designs can:

•Guide several conductors through a single ceramic body

•Provide channels for fluids or gases

•Shape creepage and clearance paths for high-voltage design

This approach helps engineers pack more function into a tight space while still meeting insulation, safety, and regulatory targets.

- Precision that Supports High Yields

Even a small dimensional error in an insulator can cause alignment issues, stress on pins, or sealing problems. That often shows up as assembly scrap, unexpected rework, or field returns.

UPCERA's machining capabilities include:

•Tolerances typically down to ±0.01 mm

•Lengths up to around 300 mm

•Minimum wall thickness close to 0.1 mm for compact structures

•Fine surface finishes, with roughness as low as Ra 0.02 - 0.2

For our customers, this level of precision directly supports higher yields. Parts fit correctly, seals work as designed, and assemblies behave consistently from one production batch to the next.

- Compliance and Global Readiness

For many engineering teams, technical performance is only half the story. The other half is documentation: passing audits, meeting standards, and simplifying approvals in different markets.

UPCERA's alumina components are:

✅RoHS compliant

✅REACH compliant

This makes Custom Ceramic Insulators from UPCERA easier to integrate into systems that ship worldwide, and it reduces the time your team spends on compliance paperwork and back-and-forth with customers.

When to Consider Custom Ceramic Insulators – and How UPCERA Can Help

Custom parts make the most sense when the insulator is no longer just a passive spacer but a critical part of your performance and safety strategy.

You will usually see the value of custom alumina solutions when:

•Standard insulators cannot handle your voltage, temperature, or chemical environment

•You need thin walls, multi-hole paths, or other complex geometries

•Your design is moving to higher power density in a smaller footprint

•Long-term reliability, process cleanliness, or certification is a key selling point

- A Simple Path From Idea to Production

A typical project with UPCERA for Custom Ceramic Insulators looks like this:

1) Share the basics

You send us your drawing, model, or even a rough sketch plus key requirements: operating voltage, temperature range, environment, and target dimensions.

2) Co-engineering and optimization

Our team reviews feasibility, suggests alumina grades, and proposes practical tolerances, hole sizes, and wall thicknesses that balance performance and cost.

3) Prototype and test

You validate electrical insulation, fit, and thermal behavior in your actual system, not just in a lab fixture.

4) Stable mass production

Once the design is confirmed, we lock in processes and quality controls to deliver consistent batches over the lifetime of your project.

Throughout this process, our focus is clear: lower your technical risk, simplify your supply chain, and help your team move faster from design to reliable production.

Call to Action: Turn Insulation into a Strength

If you are re-evaluating your insulation strategy or starting a new high-reliability design, Custom Ceramic Insulators from UPCERA can give you more control over performance, lifetime, and compliance.

Share your project details - voltage, temperature, environment, and key dimensions - with our engineering team, and we will help you define a suitable alumina ceramic solution and achievable tolerances.

With the right custom insulator in place, insulation stops being a hidden weak link and becomes one of the strongest parts of your system.

English

English 中文

中文