Custom Ceramic Rods Supplier Indonesia

A premier Custom Ceramic Rods Supplier Indonesia is an essential partner for the nation's advanced industrial sector. These specialized suppliers provide components that are engineered for specific, demanding applications. Standard, off-the-shelf rods cannot meet the challenges of unique machinery or extreme environments. Custom rods are not just parts; they are engineered solutions. They are designed in partnership with the customer. This ensures a perfect fit, optimal material performance, and maximum service life.

The local industrial landscape is diverse. It includes oil and gas, petrochemicals, power generation, and advanced manufacturing. These industries all rely on equipment that operates under high stress. A local supplier bridges the gap. They connect the region's engineering needs with world-class manufacturing capabilities. They provide technical expertise, manage logistics, and deliver high-performance parts. This article explores the world of custom ceramic rods. It details the design process, material options, and critical applications.

What Defines a "Custom" Ceramic Rod?

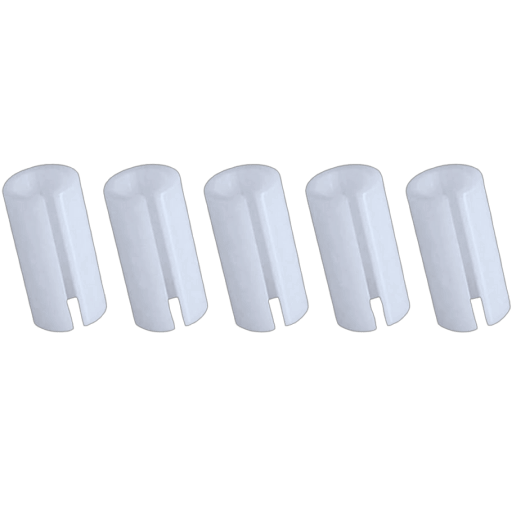

The term "custom" goes far beyond simply cutting a standard rod to a specific length. A custom-ceramic-rods manufacturer provides parts that are made to a customer's exact drawing. Standard ceramic-rods-indonesia are mass-produced with basic specifications. Custom rods are individually engineered.

Moving Beyond Standard Stock Sizes

Standard rods are typically sold in simple diameters and lengths. They are commodity products. Customization means creating a new component from the ground up. This involves specific features that cannot be found in a catalog.

Common Customization Features

A Custom Ceramic Rods Supplier Indonesia works with manufacturers to create complex geometries. This is achieved through advanced forming and precision diamond grinding.

- Threads: Internal (tapped) or external (ground) threads. These are used for assembly.

- Grooves: Precision-ground grooves for o-rings, retaining clips, or locating.

- Flats: One or more flat surfaces ground onto the rod. This is for wrenches or for keying.

- Tapers: Rods can be tapered to a precise angle.

- Holes: Cross-drilled holes for pins or mounting.

- Non-Standard Diameters: Diameters can be held to extremely tight tolerances.

- Specific Surface Finishes: Rods can be lapped and polished. This is for sealing or low-friction applications.

The Role of an Industrial Ceramic Rod

An industrial-ceramic-rod is designed for work. In a custom application, it is a critical machine part. It may be a plunger, a shaft, a nozzle, or a positioning pin. Its custom features allow it to integrate perfectly with other components.

The Co-Engineering Process: A Partnership

Sourcing a custom rod is a collaborative process. It is a partnership between the customer and the supplier's engineering team.

Phase 1: The Technical Drawing

The customer provides a detailed technical drawing. This is the blueprint for the part. This drawing must include:

- All dimensions and their tolerances.

- The material specification (e.g., 99% Alumina).

- The required surface finish.

- All special features like threads or holes.

Phase 2: Design for Manufacturability (DFM)

A premier supplier will not just provide a quote. They will perform a Design for Manufacturability (DFM) review. Their engineers will analyze the drawing. They will look for potential problems.

- Are the tolerances too tight for the application?

- Is there a way to make the part stronger?

- Could a small design change make it much cheaper to produce?

This DFM feedback is one of an expert supplier's most valuable services.

Phase 3: Tooling and Prototyping

Once the design is final, custom tooling may be needed. This could be a new extrusion die or a custom mold. The manufacturer will then produce a small "first article" batch. This prototype is inspected. A First Article Inspection (FAI) report is sent to the customer. This report verifies that the part meets every dimension on the drawing.

Phase 4: Full-Scale Production

After the customer approves the prototype, full-scale production begins. The supplier manages this process. They ensure quality is maintained from the first part to the last.

The Value of a Local Supplier in Indonesia

Choosing a local Custom Ceramic Rods Supplier Indonesia offers significant strategic advantages. This is compared to sourcing directly from an unknown overseas factory.

Supporting the Local Industrial Economy

A local supplier is invested in the region's success. We understand the specific challenges of the local industrial base. They help local companies compete. They provide access to advanced materials.

Overcoming Logistics and Import Challenges

Importing technical components can be difficult. It involves complex customs procedures, tariffs, and long shipping times. A local supplier handles all of this. They manage the importation. They clear the parts through customs. The customer has a simple, local purchasing experience.

Providing Local Technical Support and Expertise

A local supplier provides on-the-ground support. They can visit a customer's facility. They can see the application firsthand. Their technical team is in the same time zone. This makes communication fast and easy.

Just-in-Time (JIT) Inventory for Local Operations

A local supplier can hold inventory for their customers. An assembly plant does not need to store thousands of parts. The supplier holds the stock. They deliver the parts as needed. This is a just-in-time (JIT) solution. It improves cash flow for the customer.

Core Materials for Custom Rods

The material choice is the most critical decision. It dictates the rod's performance.

Alumina (Aluminum Oxide)

Alumina (Al2O3) is the most common technical ceramic. It is a versatile workhorse. It is valued for its high hardness, good thermal stability, and excellent electrical insulation.

- 95% Alumina: A good all-purpose material.

- 99% Alumina: Offers better electrical insulation and wear resistance.

- 99.8%+ Alumina: High-purity grades are used for medical and semiconductor applications. They offer superior chemical resistance.

Custom rods made from alumina are often used as electrical insulators, furnace supports, and wear-resistant guides.

Zirconia (Zirconium Oxide)

Zirconia (ZrO2) is a premium ceramic material. It is known for its extreme toughness. While alumina is hard but brittle, zirconia is tough. It can resist impact and mechanical stress.

- Y-TZP (Yttria-Stabilized Zirconia): This is the most common grade. Its high fracture toughness makes it ideal for mechanical parts.

- Low Thermal Conductivity: Zirconia is a thermal insulator. It blocks heat.

- High Strength: It has a very high flexural strength.

Custom zirconia rods are used for plungers, shafts, and sealing components.

The Custom Manufacturing Process: A Detailed Look

A Custom Ceramic Rods Supplier Indonesia partners with manufacturers who have mastered a complex process. This process turns fine powder into a precision-ground component.

Step 1: Material Formulation

The process begins with ultra-pure ceramic powder. This powder is mixed with binders. The binder mixture is a proprietary recipe. It allows the powder to be formed.

Step 2: Forming the "Green Part"

The rod must be shaped before it is fired. This is the "green part."

- Extrusion: This is common for rods. The ceramic paste is forced through a die. The die has a circular opening. This creates a long, continuous green rod. It is then cut to length.

- Isostatic Pressing: The powder is put in a flexible mold. The mold is pressurized. This forms a very dense and uniform green part. This is good for large or complex shapes.

Step 3: Sintering and Binder Burnout

The green rod is fragile. It is placed in a large, high-temperature furnace.

- Binder Burnout: The rod is heated slowly. The binders are burned away.

- Sintering: The temperature is raised much higher. This is often over 1600°C. The ceramic particles fuse. The part shrinks by 15-25%. It becomes incredibly hard and dense.

Step 4: Precision Diamond Grinding (The "Custom" Stage)

After sintering, the rod is extremely hard. It can only be machined with diamond-coated tools. This is where most custom features are created.

- Centerless Grinding: The rod is spun between two diamond wheels. This grinds the outer diameter to a precise, uniform size. It can achieve tolerances of just a few microns.

- Grinding Threads: A specialized diamond grinding wheel is used. It has the profile of the thread. It is slowly fed into the rod.

- Grinding Grooves and Flats: Shaped diamond wheels are used. They plunge-grind the features into the rod.

- Drilling: Diamond-tipped drills are used. This is a slow, high-wear process.

Step 5: Lapping and Polishing

For some applications, a standard ground finish is not smooth enough.

- Lapping: The rod is "lapped" with a diamond paste. This creates a very flat, smooth surface.

- Polishing: A final polish can create a mirror-like finish. This is needed for high-performance seals.

Step 6: Final Quality Assurance

The finished custom rod is sent to a metrology lab.

- A Coordinate Measuring Machine (CMM) checks all dimensions.

- A laser micrometer checks the diameter.

- A surface profilometer checks the surface finish.

Only parts that pass this 100% inspection are shipped.

Key Properties of High-Strength Ceramic Rods

Custom rods are often specified as high-strength-ceramic-rods. Their properties are far superior to metal.

Extreme Temperature Resistance

This is a primary benefit. Alumina rods can operate at 1500°C or more. Metal rods would melt or deform. This makes them ideal for furnace parts.

Superior Wear and Abrasion Resistance

Zirconia and alumina are extremely hard. They are much harder than tool steel. In a manufacturing line, a ceramic guide rod will last 10-20 times longer than a metal one.

Electrical Insulation Properties

Technical ceramics are excellent electrical insulators. They have a high dielectric strength. This means they can withstand a high voltage. Custom rods with threads and holes are used. They build high-voltage switchgear.

Chemical and Corrosion Resistance

Ceramic rods are chemically inert. They do not react with acids or alkalis. This is vital for the local oil, gas, and chemical industries. A metal rod would corrode. A ceramic rod will last for years.

Critical Applications in the Region's Industries

A Custom Ceramic Rods Supplier Indonesia serves the nation's key industries.

Oil, Gas, and Petrochemical

This sector is a major user of custom ceramics.

- Valve Components: Custom zirconia balls and stems are used in corrosive-fluid valves.

- Sensor Housings: Custom rods are machined to house downhole sensors. They must withstand heat, pressure, and corrosion.

- Pump Plungers: Zirconia plungers are used for high-pressure injection pumps.

Power Generation and Distribution

- High-Voltage Insulators: Custom alumina rods are used. They support bus bars and other components.

- Turbine Components: Ceramic parts are used in the hot sections of turbines.

- Boiler Components: Custom tubes and rods are used for sensors.

Pulp, Paper, and Palm Oil Manufacturing

These industries are highly abrasive and corrosive.

- Dewatering Foils: Ceramic blades and rods are used. They scrape water from the paper pulp.

- Sealing Rings: Custom-lapped zirconia rings are used in mechanical seals.

- Wear Liners: Custom ceramic parts protect machinery from abrasive palm kernels.

Advanced Research and Niche Applications

The field of ceramics is always advancing. Some materials are even processed to be clear. This creates optical uses for transparent ceramics. These are used in lasers and high-tech sensors.

A local supplier is part of a global network.

- They benchmark their quality against high-spec markets. This includes ceramic-rods-usa and ceramic-rods-europe.

- They provide a local advantage. This advantage is over sourcing standard parts from global hubs.

How to Choose a Custom Ceramic Rods Supplier Indonesia

Choosing the right partner is critical for success.

- Verify Engineering Capabilities: Do they have engineers? Can they read your drawings? Can they provide DFM feedback?

- Ask About Machining Tolerances: A good supplier will be honest. They will tell you their standard tolerances.

- Demand ISO 9001 Certification: This is the baseline for a quality supplier.

- Request Material Data Sheets: Always get a data sheet. It proves the material is what they claim.

- Evaluate Technical Support: A good supplier is a partner. They will help you solve your problem. They should be ablef to provide a ceramic-rods-guide.

Conclusion

A Custom Ceramic Rods Supplier Indonesia is a high-value, strategic partner. They are not just a vendor. They are an engineering resource. We provide the local expertise to solve complex material challenges. They manage a global supply chain. They deliver precision-engineered components. These parts allow local industries to run faster, hotter, and more efficiently.

In This Article

- 1 What Defines a "Custom" Ceramic Rod?

- 2 The Co-Engineering Process: A Partnership

- 3 The Value of a Local Supplier in Indonesia

- 4 Core Materials for Custom Rods

- 5 The Custom Manufacturing Process: A Detailed Look

- 6 Key Properties of High-Strength Ceramic Rods

- 7 Critical Applications in the Region's Industries

- 8 Navigating the Global Supply Chain Context

- 9 How to Choose a Custom Ceramic Rods Supplier Indonesia

- 10 Conclusion

English

English 中文

中文