Custom Ceramic Sleeves Manufacturer: A Complete Sourcing Guide

Finding a custom ceramic sleeves manufacturer is the first step in solving a problem that standard parts cannot. Your project may involve extreme temperatures, severe abrasion, or a unique physical size. Off-the-shelf components simply will not fit or will fail quickly. This guide is for engineers, designers, and procurement teams. It details the entire process, from creating a technical drawing to selecting the right material and vetting a manufacturing partner.

We will explore the design specifications that matter. We will compare the most common advanced ceramic materials. Finally, we will show you how to find a supplier with the right engineering skills. This guide will help you get your custom part made correctly the first time.

What Is a Custom Ceramic Sleeve?

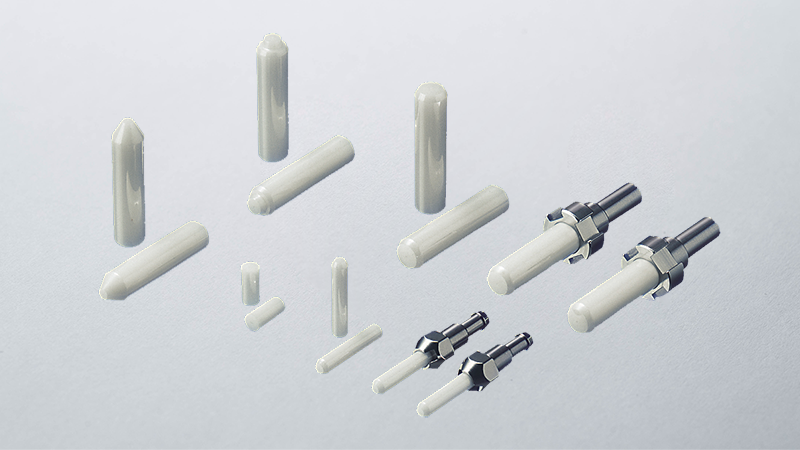

A custom ceramic sleeve is a high-performance component engineered to your exact specifications. Unlike standard sleeves, which are mass-produced in fixed sizes, a custom sleeve is made to order. This means you define the material, the dimensions, and any special features.

What makes a ceramic sleeve "custom"?

A ceramic sleeve is "custom" when it is manufactured to a customer's unique technical drawing. This can include non-standard inner and outer diameters, specific lengths, and special features like flanges, grooves, or sensor holes. The material choice and dimensional tolerances are also specified by the customer.

Standard sleeves, like those in fiber optics, are made by the million. Custom manufacturing is a low-volume, high-precision process. It is a partnership between you and the manufacturer.

When Standard Parts Are Not Good Enough

You need a custom sleeve when your application demands it.

- Prototyping: You are developing a new product. You need a few parts to test a design before committing to mass production.

- Retrofitting: You are repairing or upgrading old machinery. The original parts are no longer available. You need a replacement that fits existing equipment.

- Unique Environments: Your sleeve must survive conditions like molten metal, strong acids, or high-voltage electricity.

- Specific Tolerances: Your part must mate with another component. It requires a level of precision (tightness or looseness) that standard parts do not offer.

Part 1: The Design Process (How to Specify Your Sleeve)

You cannot just ask a manufacturer for a "custom sleeve." You must provide a clear and detailed technical drawing. This drawing is the most important document in the entire process.

How do you design a custom ceramic sleeve?

To design a custom sleeve, create a technical drawing (a CAD file or PDF). This drawing must specify all critical dimensions like inner diameter (ID), outer diameter (OD), and length. You must also define the material (e.g., Alumina) and the required tolerances for each dimension.

Step 1: Define Critical Dimensions and Tolerances

Tolerances define the "acceptable range" for a dimension. They are the most common point of failure in a custom project. Be realistic. Tighter tolerances mean higher costs.

- Inner Diameter (ID): How large is the hole? This is often the most critical dimension.

- Outer Diameter (OD): How large is the part's outside?

- Length (L): How long is the sleeve?

- Concentricity (or TIR): How perfectly centered is the ID relative to the OD? This is vital for rotating parts like shafts and bearings.

- Cylindricity: How "round" is the part?

A good manufacturer will review your drawing. They may suggest loosening a tolerance on a non-critical dimension to save you money.

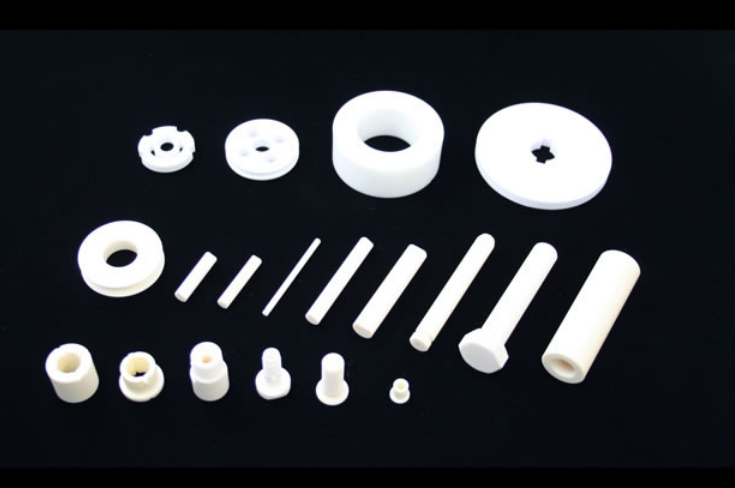

Step 2: Add Custom Features

This is what makes your part truly custom. Your drawing must clearly show these features.

- Flanges: A "lip" or "rim" at one end, used for mounting.

- Grooves: Notches cut into the OD or ID, often for O-rings or clips.

- Slots: Cuts made through the part.

- Holes: Drilled through the wall of the sleeve, perhaps for a sensor, a pin, or a set screw.

- Chamfers: Beveled edges to make insertion easier.

Step 3: Specify Surface Finish (Ra)

Surface finish (Ra) measures the smoothness of a surface.

- A low Ra (very smooth): This is needed for bearing surfaces or seals. A mirror-like finish reduces friction and wear.

- A high Ra (rougher): This may be desired in applications where a coating needs to adhere to the ceramic.

Achieving a low Ra requires extra lapping and polishing steps. This increases the cost. Only specify a mirror finish if your application truly needs it.

Part 2: Choosing the Right Ceramic Material

The manufacturer will ask you what material to use. Your choice depends entirely on your application. An expert manufacturer can help you decide, but you should know the basics.

What are the most common custom ceramic materials?

The most common materials are Alumina, Zirconia, and Silicon Carbide. Alumina (Al2O3) is used for high temperatures and electrical insulation. Zirconia (ZrO2) is used for high strength and fracture toughness. Silicon Carbide (SiC) is used for extreme abrasion and wear resistance.

Alumina (Aluminum Oxide, Al2O3)

Alumina is the workhorse of advanced ceramics. It is common and relatively low-cost.

- Best For: High temperatures (up to 1700°C), high-voltage electrical insulation, and good wear resistance.

- Common Use: Furnace components, insulators, sensor protection tubes.

- Weakness: It is more brittle than Zirconia.

Zirconia (Zirconium Oxide, ZrO2)

Zirconia is often called "ceramic steel." It has incredible fracture toughness, meaning it resists cracking and chipping.

- Best For: High-stress applications, guides, or any part that might experience impact or high loads.

- Common Use: Fiber optic sleeves, medical implants, pump components, cutting tools.

- Weakness: Lower temperature limit than Alumina (around 1000°C).

Silicon Carbide (SiC)

Silicon Carbide is one of the hardest materials on earth, second only to diamond.

- Best For: Extreme abrasion and wear. If your sleeve is in a slurry of sand and water, this is your material.

- Common Use: Pump seals, valve liners, nozzles for sandblasting.

- Weakness: Can be more expensive and difficult to machine.

Nitride (Si3N4)

Silicon Nitride is a specialist material. Its superpower is thermal shock resistance.

- Best For: Rapid temperature changes. You can heat it red hot and drop it in water without it cracking.

- Common Use: Molten metal handling tools, high-performance bearings, automotive engine parts.

- Weakness: Tends to be the most expensive option.

Here is a simple comparison:

| Feature | Alumina (Al2O3) | Zirconia (ZrO2) | Silicon Carbide (SiC) |

| Max Temperature | Very High | Medium | High |

| Hardness (Wear) | High | High | Extreme |

| Toughness (Crack Res.) | Fair | Very High | Good |

| Electrical Insulator | Excellent | Good | No (Conductive) |

| Cost | Low | Medium | High |

Part 3: The Custom Manufacturing Process

How does a manufacturer turn your drawing into a physical part? It is a multi-step process that combines molding and machining.

How are custom ceramic sleeves made?

The process starts by forming a "green part" from ceramic powder using methods like extrusion or pressing. This soft part is then fired at over 1600°C in a furnace (sintering) to make it dense and hard. Finally, the sleeve is precision-ground with diamond tools to meet the custom drawing's exact dimensions.

Step 1: Forming the "Green Part"

The raw ceramic powder is mixed with a binder. This paste is then shaped into a rough form of the final part. This is the "green part."

- For simple tubes: Extrusion is used. The paste is pushed through a die, like pasta.

- For complex shapes: Ceramic Injection Molding (CIM) or dry pressing is used. The powder is pressed into a mold.

The green part is soft and chalky. It is also made oversized to account for shrinkage.

Step 2: Sintering (Firing)

This is the most critical step. The green part is placed in a high-temperature kiln for many hours, sometimes days.

- Binder Burnout: The binder is slowly burned away.

- Sintering: At extreme temperatures (1600°C+), the ceramic particles fuse. The part shrinks by 15-25% and becomes incredibly hard and dense.

Any mistake in this step can cause the part to crack or warp.

Step 3: Diamond Grinding

After sintering, the part is hard, but its dimensions are not precise. The final step is to "machine" the part to your drawing's tolerances. Since the ceramic is so hard, this can only be done with diamond tools.

- Outer Diameter (OD) Grinding: The part is spun on a cylindrical grinder.

- Inner Diameter (ID) Grinding: A small diamond-tipped tool grinds the inside bore.

- Lapping/Polishing: To get a mirror finish (low Ra), the part is lapped with a fine diamond slurry.

This grinding stage is what defines a custom manufacturer. It is slow, expensive, and requires a high level of skill.

Part 4: How to Find and Vet Your Manufacturer

Not all manufacturers are created equal. Some are just distributors. Others are high-volume factories that cannot handle a custom order for 10 pieces.

How to choose a custom ceramic sleeves manufacturer?

Choose a manufacturer based on their engineering skill. Ask if they offer design support. Verify they have in-house diamond grinding capabilities. Review their quality control process and ask to see sample parts. Finally, be sure to discuss their minimum order quantities (MOQs) and lead times.

Here is a 4-step process for vetting a potential partner.

Step 1: Look for Engineering Expertise

A true custom manufacturer is an engineering partner.

- Ask them: "Can you review my drawing for manufacturability?"

- Good Answer: "Yes. We see you have a very tight tolerance on this groove. Is it critical? We can save you 30% if we can open it up by 0.05mm."

- Bad Answer: "Send PO."

You want a partner who can offer solutions, not just a price.

Step 2: Verify Their Capabilities

You must confirm they can do the hardest part: the grinding.

- Ask them: "Do you do your own diamond grinding in-house?"

- Why it matters: A company that outsources its grinding is just a middle-man. They have no control over quality or lead time.

- Ask for: Photos of their grinding equipment. Ask about their CMM (Coordinate-Measuring Machine) or other inspection tools.

Step 3: Discuss MOQs and Lead Times

This is a practical hurdle.

- Minimum Order Quantity (MOQ): Setting up a custom grinding job takes time. Many factories will not want to make just one piece. Ask, "What is your MOQ for this part?" or "Do you offer a prototyping service?"

- Lead Time: Be patient. Sintering takes days. Grinding is slow. A typical custom order can take 4 to 12 weeks. Do not trust a supplier who promises 5 days.

Step 4: Check Their Quality Control

How do they prove the part matches your drawing?

- Ask them: "What inspection report will I receive with my order?"

- A good supplier: Will provide a "First Article Inspection Report" (FAIR). This report lists every dimension on your drawing and shows the actual measured dimension of the part they produced. This is your proof of quality.

Part 5: Sourcing Custom Sleeves: A Global Perspective

Your search for a manufacturer will take you around the world. Different regions have different specialties.

- Custom Sleeves from China: The ceramic sleeves China market is vast. It offers excellent value and high-volume capacity. The challenge is vetting. You must separate the true, high-tech manufacturers from the thousands of trading companies.

- Custom Sleeves from Germany: The market for ceramic sleeves in Germany is known for extreme precision. These manufacturers are masters of engineering and often focus on complex parts for automotive and industrial automation.

- Custom Sleeves from Europe: Sourcing ceramic sleeves in Europe gives you access to a strong industrial base with a focus on quality and material science.

- Custom Sleeves from the USA: The ceramic sleeves USA market excels at high-spec materials for aerospace, defense, and medical R&D. They have a strong reputation for custom prototyping.

- Emerging Markets: Countries like India and Indonesia are building their capabilities. Sourcing a ceramic sleeves supplier in India or from the ceramic sleeves Indonesia market can be a good option for supporting local operations.

Part 6: The Future of Custom Ceramics

The technology for custom parts is getting better. Two areas are leading the way.

- Additive Manufacturing (3D Printing): It is now possible to 3D print ceramic parts. This is perfect for extremely complex shapes that are impossible to mold. The parts are printed in a "green" state and then sintered, just like a molded part.

- Advanced Composites: Researchers are creating new materials. Ceramic Matrix Composites (CMCs), for example, embed ceramic fibers (like Silicon Carbide) inside a ceramic matrix. The result is a ceramic that has all the heat resistance but is tough and non-brittle, like a metal.

Finding Your Manufacturing Partner

Working with a custom ceramic sleeves manufacturer is very different from buying a standard part. It is a relationship built on communication.

Your success depends on your technical drawing. It must be clear, complete, and realistic. Your success also depends on finding a true partner. Look for a manufacturer who has in-house grinding, robust quality control, and the engineering expertise to help you make your design better.

For a broader overview of all ceramic sleeve types, materials, and applications, please see our ultimate ceramic sleeves guide.

In This Article

- 1 What Is a Custom Ceramic Sleeve?

- 2 Part 1: The Design Process (How to Specify Your Sleeve)

- 3 Part 2: Choosing the Right Ceramic Material

- 4 Part 3: The Custom Manufacturing Process

- 5 Part 4: How to Find and Vet Your Manufacturer

- 6 Part 5: Sourcing Custom Sleeves: A Global Perspective

- 7 Part 6: The Future of Custom Ceramics

- 8 Finding Your Manufacturing Partner

English

English 中文

中文