Custom Ceramic Substrates Reshape High-Power Electronics

In the evolving landscape of electronic design, custom ceramic substrates are becoming key enablers of high-power performance, precision, and miniaturization. These advanced materials not only withstand extreme thermal and mechanical stress but also offer the reliability required by industries such as automotive, aerospace, telecom, and industrial automation.

At UPCERA, we specialize in engineering custom ceramic substrates that go beyond conventional materials. With over 2 decades of experience in ceramic manufacturing, we're proud to support global innovation with substrate solutions that are tailored to meet specific application needs.

The Growing Demand for Custom Ceramic Substrates

As electronic devices become more powerful and compact, the demand for materials that can handle high voltages, thermal loads, and mechanical stress continues to grow. Custom ceramic substrates offer a superior alternative to traditional PCB materials by delivering:

✅ High thermal conductivity for efficient heat dissipation

✅ Mechanical strength and rigidity even in compact layouts

✅ Outstanding chemical and corrosion resistance

✅ Precise dimensional tolerances for critical components

✅ Excellent electrical insulation for high-voltage applications

These advantages make custom ceramic substrates a go-to choice in systems where standard materials fall short—especially in high-reliability and mission-critical environments.

Why Alumina Stands Out as a Substrate Material

Among ceramic materials, alumina (Al₂O₃) is one of the most widely used in custom ceramic substrates due to its excellent combination of thermal, mechanical, and electrical properties.

• Key Advantages of Alumina-Based Substrates

✅ Exceptional hardness and wear resistance

✅ Thermal stability up to 1500°C

✅ Electrical insulation properties

✅ Corrosion resistance in harsh environments

✅ Compatibility with various metallization techniques

These features make alumina an ideal base for components in power modules, RF systems, laser equipment, and more. At UPCERA, we machine alumina to tight tolerances, enabling precise fits in high-density assemblies and high-speed automation systems.

How Custom Ceramic Substrates Enhance High-Power Electronics

Custom ceramic substrates play a vital role in optimizing the performance and efficiency of high-power electronics. They serve not just as mechanical supports but also as functional materials that impact the system's electrical behavior and heat management.

• Benefits in High-Power Applications

• Thermal Management: Effective heat dissipation ensures longer device life and prevents thermal runaway.

• Electrical Isolation: Withstand high voltages without breakdown, especially in IGBT and power MOSFET modules.

• Mechanical Stability: Maintain structure and alignment under vibration, pressure, or thermal cycling.

• Design Flexibility: Custom shaping allows integration into complex assemblies, saving board space.

Applications benefiting from these features include EV battery systems, industrial drives, LED lighting, and solar inverters—all of which demand stable, efficient, and reliable substrate materials.

Where Custom Ceramic Substrates Are Making an Impact

Custom ceramic substrates are proving essential across a wide range of high-performance industries. Their durability, precision, and ability to withstand harsh environments make them ideal for applications where conventional materials often fail.

• Electronics & Semiconductors

In advanced electronic systems, custom ceramic substrates provide excellent thermal management and electrical insulation. They're widely used in:

• Power amplifier circuits for stable high-frequency performance

• LED chip carriers that ensure heat dissipation and longevity

• RF filters and signal routing components where signal integrity is critical

• Automotive & Aerospace

The demands of these sectors require materials that resist heat, vibration, and corrosion. Ceramic substrates support:

• Power converters and inverters in electric and hybrid vehicles

• Engine control units (ECUs) requiring compact, heat-resistant bases

• Sensor packaging for critical flight and vehicle monitoring systems

• Medical Devices

Biocompatibility and precision make ceramic substrates ideal for medical innovations:

• Diagnostic tools that demand stability and accuracy

• Surgical instruments requiring sterilizable, wear-resistant materials

• Implantable components due to their inert, body-safe nature

• Industrial Automation

In automated environments, reliability and mechanical strength are key. Ceramic substrates perform in:

• Robotic arms and sensor mounts requiring rigidity and precision

• High-speed machinery exposed to heat and mechanical stress

• Control modules that endure continuous operation under tough conditions

These diverse applications highlight the growing demand for tailored ceramic solutions—each engineered to meet strict performance and environmental standards.

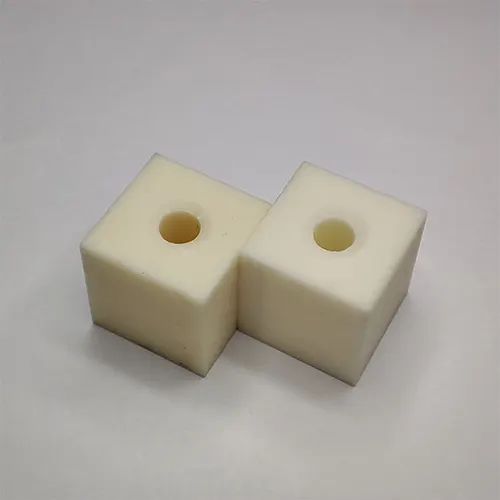

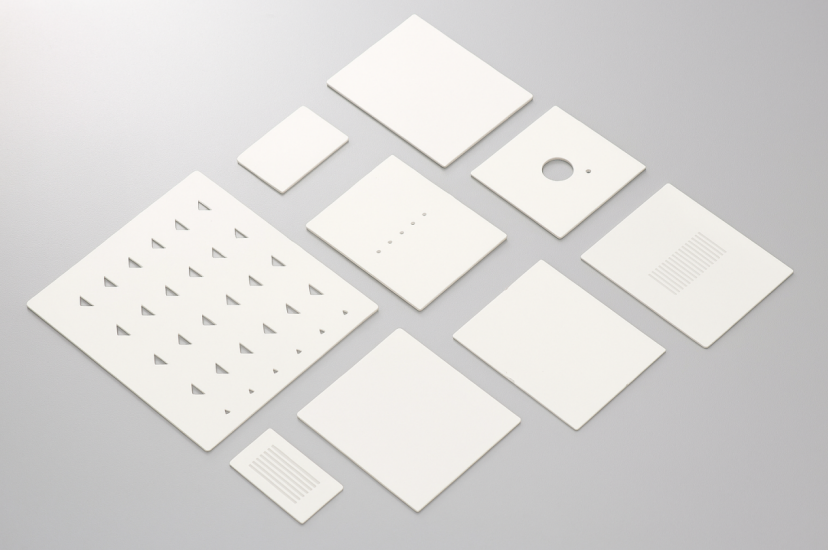

What Sets UPCERA Apart in Ceramic Substrate Manufacturing

At UPCERA, we don't just manufacture ceramic substrates—we co-engineer performance with our clients. Our focus is on delivering:

✅ Custom geometries and dimensions

✅ High-precision machining

✅ Surface treatments and metallization

✅ Prototype-to-production scalability

With our state-of-the-art facilities and technical team, we can respond quickly to evolving project requirements and help our partners reduce development time without compromising quality.

We offer various substrate materials including alumina, zirconia, and other advanced ceramics, and we continuously innovate to meet the growing demands of modern electronics.

Future Outlook

As electronics continue to evolve, the role of custom ceramic substrates will only become more critical. With advancements in miniaturization, AI, and power density, the need for materials that provide thermal, mechanical, and electrical reliability is more important than ever.

At UPCERA, we're committed to staying ahead of the curve. By offering customizable ceramic solutions built for tomorrow's challenges, we empower engineers to design smarter, smaller, and more powerful systems.

Conclusion

Custom ceramic substrates have evolved from a niche technology into a critical foundation for the performance, reliability, and efficiency of next-generation high-power electronics. At UPCERA, we bring together advanced material science, precision engineering, and cutting-edge manufacturing to deliver substrate solutions that meet the most demanding requirements and unlock new design possibilities.

Whether you're developing compact power modules, high-frequency systems, or rugged industrial devices, our team is here to help you engineer a substrate solution that fits your exact needs. Get in touch with us today to discover how custom ceramic substrates can elevate your product's performance.

English

English 中文

中文