How Custom Industrial Ceramics Improve Protection in Harsh Settings

Custom Industrial Ceramics are the quiet guardians of safety when heat, corrosion, voltage, or abrasive flow would destroy conventional parts. At UPCERA, we design and manufacture components that protect people, equipment, and uptime in the world's toughest workplaces.

Why Custom Industrial Ceramics Matter in Harsh Environments

Every high-risk setting has a weak link: a seal that wears, an insulator that arcs, a tube that corrodes, or a nozzle that erodes under slurry. These failures cause unplanned downtime - and in critical sectors, they can create safety incidents. Custom Industrial Ceramics solve these pain points by combining high hardness, thermal stability, electrical insulation, and chemical inertia in one engineered package.

As a manufacturer with 20+ years of ceramic manufacturing experience, UPCERA builds reliability into the part from the start. We offer factory-direct supply with guaranteed quality, tight process control, and application-specific design. Beyond standard items, we provide custom ceramic structural components for aerospace, semiconductor, medical equipment, and other demanding fields where safety margins are non-negotiable.

• Field-Proven Materials and Processes

We select materials - zirconia, alumina, and silicon carbide - to match the hazard profile. Zirconia resists impact and delivers toughness; alumina provides high dielectric strength; silicon carbide handles extreme wear and thermal shock. Using advanced molding, sintering, and precision finishing, we achieve extreme tolerance control and smooth surfaces that reduce friction, hotspots, and particle generation. Where electrical isolation and structural integration are both needed, we support ceramic-metal assemblies and metallization services to ensure stable, low-stress bonds.

• Where Safety Meets Precision - Key Applications

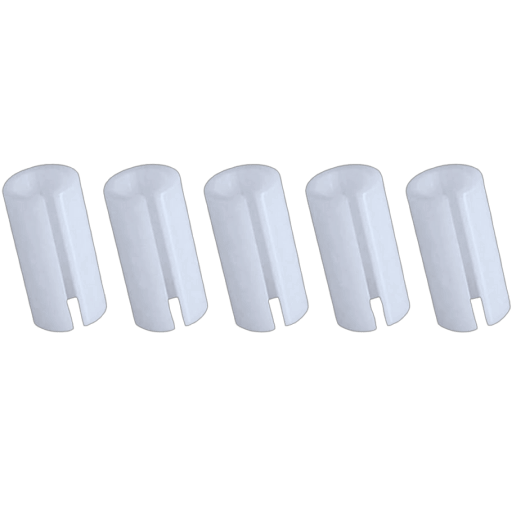

✅Bushings and nozzles: wear- and corrosion-resistant for high-precision fluid control, reducing leaks and spray hazards.

✅Square punched holes, metallized: dependable electronic and electrical insulation, cutting arcing risk in power and RF hardware.

✅Engraving/printing, metal-bonding parts: robust ceramic-metal assemblies that maintain alignment and strength under thermal cycling.

✅Special-shaped structural parts: non-standard geometries for guards, shields, and fixtures that prevent contact with hot or live zones.

✅Ceramic tubes: reliable conduits for fluid transport, temperature-probe protection, and insulation supports in extreme environments.

✅Ceramic ferrules: precise fiber alignment for optical networks in data centers, FTTx, and 5G infrastructure, supporting stable, low-loss links.

✅Ceramic rods and pins: bearings, seals, probes, and locator pins that keep mechanisms aligned and safe at speed and temperature.

Engineering for Risk Reduction with Custom Industrial Ceramics

Safety is not a single property; it is a system outcome. Our engineers look at load cases, temperature bands, chemistry, dielectric demands, and maintenance realities to design parts that prevent failure modes before they start.

• Tolerances, Surfaces, and Stability

Micron-level fits and fine surface finishes reduce wear, heat, and vibration - all common triggers of unsafe behavior. For example:

•Ceramic ferrules (high-purity zirconia) maintain tight concentricity, protecting optical signal integrity in mission-critical networks and test equipment. We support end-face polishing and laser marking for identification and traceability.

•Ceramic tubes come in standard and non-standard configurations. We tailor sizes, tolerances, and special structures to your assemblies so probes stay seated, insulation gaps remain consistent, and media stay contained - extending service life and cutting maintenance trips.

•Ceramic rods (solid, hollow, stepped, threaded, plungers, locating pins) deliver high mechanical strength and durable surfaces for bearings and seals, guarding against seizure and leaks in machinery, semiconductors, medical, and chemical systems.

• Safer by Design, Not by Chance

A robust safety component must do more than survive; it must make the system easier to operate safely. That's why we design for clearances that resist thermal drift, geometries that self-locate, and interfaces that simplify assembly. With custom production available and various ceramic materials in stock, we can align the part to your standards and validation plan - reducing qualification risk and accelerating deployment.

From Problem to Proof: How UPCERA Delivers

When you bring us a challenge - erosion in a slurry nozzle, contamination in a vacuum line, arcing in an RF stage - we translate hazards into material choices, shapes, and tolerances. Our high-precision custom processing turns concepts into components that work the first time and keep working.

• What You Can Expect from UPCERA

✅Application-driven design: we map threats (heat, wear, voltage, corrosion) to the right ceramic and geometry.

✅Prototype to volume: stable production for consistent performance across batches.

✅Integrated solutions: metallized ceramic components and ceramic-metal assemblies for safe, compact builds.

✅Efficiency and value: factory-direct pricing, fast delivery on our strong tube portfolio, and parts that lower total cost by extending life.

Our portfolio is broad - bushings and nozzles, square punched holes (metallized), special-shaped structural parts, ceramic tubes, ferrules, and rods - but the goal is singular: safer, cleaner, longer-lasting operation in harsh environments. Most deployments report fewer line stops, more reliable insulation, and cleaner processes because ceramics do not corrode, shed, or creep like metals and polymers.

Call to Action: If your team is battling heat, corrosion, arcing, or abrasive wear, talk to UPCERA. Share your drawings or describe the failure mode, and our engineers will recommend Custom Industrial Ceramics that raise safety margins and reduce maintenance. Let's turn your high-risk point into a durable, certifiable strength.

English

English 中文

中文