Custom-Made Ceramic Parts Offer Durable Solutions for High-Tech Demands

High-tech industries demand materials that can stand extreme conditions. Among them, custom-made ceramic parts are quietly transforming industries. Known for their strength, heat resistance, and precision, these parts are now essential in everything from aerospace to medical devices.

But what makes them so reliable? And why are more engineers choosing ceramics over metal or plastic? The answers may surprise you. Whether you're designing advanced electronics or cutting-edge machinery, understanding the role of custom-made ceramic parts could change the way you build.

In the following sections, we'll explore how these tiny components handle big challenges — and why they're shaping the future of high-performance technology.

Why High-Tech Industries Demand More

The Challenge of Extremes

Modern industries face extreme working conditions. High temperatures, strong chemicals, and constant wear are common. Standard materials often fail in these environments. Engineers need stronger, more reliable solutions.

Custom-Made Ceramic Parts as a Game Changer

Custom-made ceramic parts provide a smart solution. They can handle heat, resist corrosion, and maintain precision. These parts are designed for specific tasks. Their performance helps machines last longer and run better.

Understanding Custom-Made Ceramic Parts

What Are They?

Custom-made ceramic parts are precision components made from advanced ceramic materials. Each part is designed based on customer needs. This includes size, shape, material, and special functions. We can create simple or highly complex parts.

Core Advantages of Custom-Made Ceramic Parts

Ceramic materials offer key advantages:

- Durability: Ceramics resist wear and last longer.

- Precision: They can be made to exact dimensions.

- Insulation: Ceramics resist electricity, making them ideal for electronics.

- Lightweight: Despite being strong, they are lighter than metals.

These benefits make custom-made ceramic parts valuable in many fields.

Industries That Rely on Them

Many high-tech industries depend on custom-made ceramic parts. These include:

- Aerospace: For components that must endure heat and friction.

- Semiconductors: For clean, precise, and non-conductive parts.

- Medical Devices: For bio-safe, corrosion-resistant components.

- Electronics: For insulating and heat-managing parts.

Custom-made ceramics support both innovation and reliability in these fields.

UPCERA: Leading The Ceramic Innovation Frontier

Born From Academia

We are UPCERA. Our roots trace back to Tsinghua University, a leader in ceramic research. This foundation gives us deep knowledge in materials science. We turn advanced theory into real-world products.

20+ Years of Manufacturing Excellence

For over 20 years, we have focused on ceramics. We understand every part of the process—from raw materials to final products. Our experience helps us produce high-quality, custom-made ceramic parts for global industries.

Factory-Direct, Quality-Assured Supply

We offer direct factory supply. This means better prices and faster delivery. Every product meets strict quality standards. We control each step to ensure consistency and reliability. Customers trust our process and our results.

The Power of R&D and IP

Research and development are at the heart of what we do. We work closely with Sinocera, a top name in material science. Together, we develop new ceramic materials and technologies. Our team has created more than ten ceramic categories and holds strong intellectual property rights. This gives us a clear edge in custom-made ceramic parts.

High-Precision Ceramic Bushings And Nozzles

Wear- And Corrosion-Resistance In Harsh Environments

Custom-made ceramic parts like bushings and nozzles are built to last. These parts are resistant to wear, corrosion, and high temperatures. They maintain stability in demanding conditions. This makes them ideal for fluid control systems and precision instruments.

Applications Across Key Industries

Our high-precision ceramic bushings and nozzles are widely used. In mechanical systems, they reduce wear and improve efficiency. In medical devices, they ensure cleanliness and reliability. In the semiconductor field, they offer unmatched chemical resistance.

Multiple Material Options For Custom Needs

We offer several ceramic materials to meet different requirements. These include alumina, zirconia, and silicon carbide. Each material has unique strengths. We help our customers select the right one based on their application.

Metallized And Special-Function Ceramics

Square Punched Holes And Metallized Surfaces

Our custom-made ceramic parts include products with square holes and metallized finishes. These are especially useful in electronics. They provide insulation while supporting stable structure. Metallized surfaces allow for electrical connectivity where needed.

Reliable Metal-Ceramic Bonding Solutions

We specialize in metal-ceramic bonding. This process joins ceramics to metal parts. It improves strength and enhances the overall design. These parts are used in high-end electronic components and sensors.

Support For Assembly And Metallization Services

We don't just make the parts. We also support complete assembly and metallization services. This helps customers streamline their production process. From design to delivery, we ensure every detail meets your needs.

Custom-Shaped Components & Ceramic Sleeves

Special-Shaped Ceramic Structural Parts

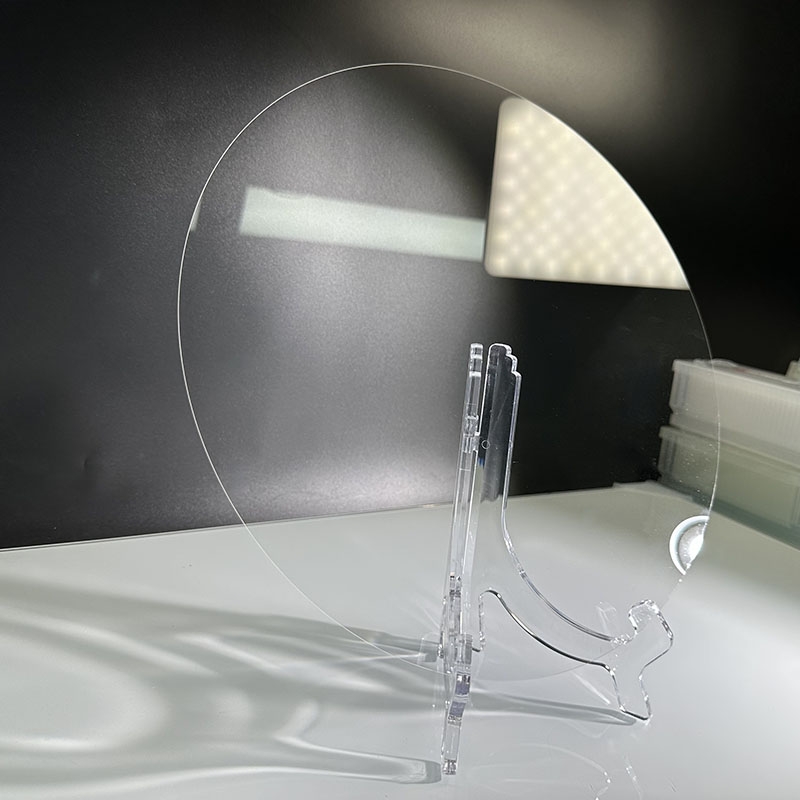

Not all components are standard. Many industries need complex, non-typical shapes. We create custom-made ceramic parts with unique geometries. Our precision machines handle even the most detailed requirements.

Ceramic Sleeves And Ferrules For Optical Use

Our ceramic sleeves and ferrules are known for their accuracy. These are key parts in optical communication. They ensure signal stability and reduce loss. Our products are trusted by global data centers and communication networks.

UPCERA's First-In-China Achievement

We are proud to be the first company in China to develop zirconia ceramic sleeves independently. Since then, we have led the market in this field. Our ceramic sleeves are now recognized worldwide for quality and performance.

Precision Ceramics Shaping The Future

Diversified Expansion Since 2017

Since 2017, we have expanded into many industries. These include aerospace, medical, semiconductors, wearables, and new energy. Our custom-made ceramic parts now support innovation across diverse fields.

Agile Customization And Scalable Production

We offer both flexibility and scale. From small batches to mass production, we respond fast to customer needs. Our team works closely with clients to provide quick design support and reliable delivery.

Closing Words: A Call To Action For Innovators

The future of high-tech depends on strong, smart materials. Custom-made ceramic parts are becoming essential in more industries. At UPCERA, we combine deep knowledge with modern tools. We invite engineers, developers, and innovators to work with us. Let's build the future together—one ceramic part at a time.

In This Article

- 1 Why High-Tech Industries Demand More

- 2 Understanding Custom-Made Ceramic Parts

- 3 UPCERA: Leading The Ceramic Innovation Frontier

- 4 High-Precision Ceramic Bushings And Nozzles

- 5 Metallized And Special-Function Ceramics

- 6 Custom-Shaped Components & Ceramic Sleeves

- 7 Precision Ceramics Shaping The Future

English

English 中文

中文