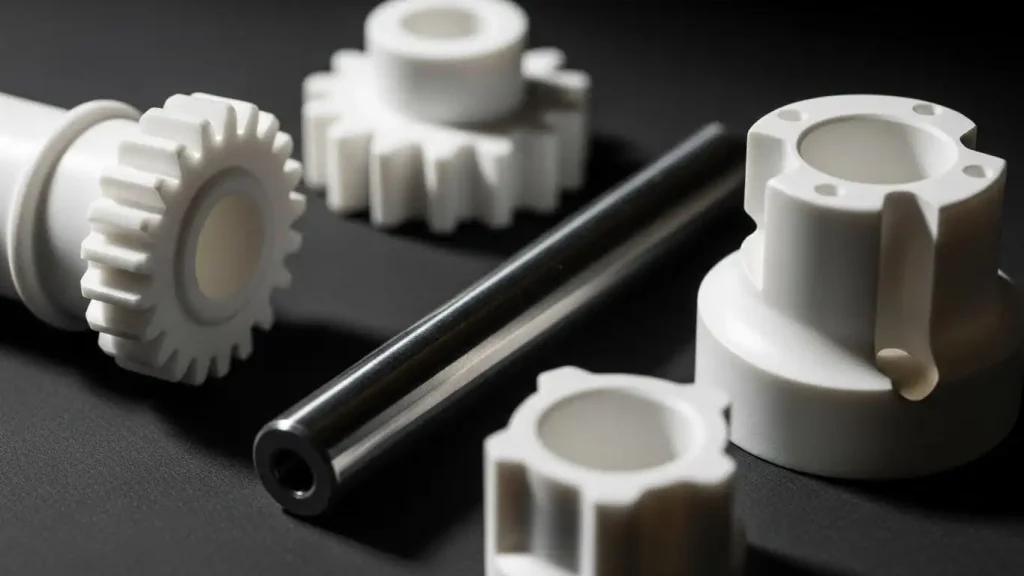

Custom Zirconia Ceramics for Demanding Industrial Needs

Custom Zirconia Ceramics are not just another "hard material." They are engineered ceramic parts made from zirconium dioxide, designed to survive where metals and plastics fail. These components offer high strength, excellent wear resistance, and strong corrosion resistance in one compact solution. From precision shafts to insulating structures, Custom Zirconia Ceramics can keep their shape and performance under heat, friction, and harsh chemicals. Many engineers already rely on them in critical positions. But how far can this material really go in demanding industrial systems - and what hidden problems can it quietly solve?

Looking Again at "Problem Parts" in Harsh Conditions

Walk through some plant or lab and you will usually find the same pain points: metal or polymer parts doing the dirtiest, hottest, or most abrasive jobs. On drawings they look fine. In operation, they live in a very different world - high temperature, continuous friction, aggressive cleaning chemicals, and fast start-stop cycles.

The result feels familiar:

•Components deform or lose geometry

•Surfaces wear far sooner than expected

•Corrosion slowly eats into precision features

•Unplanned downtime and maintenance calls keep creeping up

Custom Zirconia Ceramics offer a way to step out of this cycle. Instead of accepting that "this part just fails every few months," you can design from the beginning for high wear resistance, corrosion resistance, and dimensional stability.

What Makes Custom Zirconia Ceramics Different

Zirconia is based on zirconium dioxide (ZrO₂), but it behaves very differently from traditional ceramics. Properly stabilized and processed, zirconia parts combine high strength with notable fracture toughness. In practice, that means they can handle impact, bending, and repeated loading better than many people expect from a ceramic.

For sectors like aerospace, automotive, medical devices, semiconductor equipment, and industrial automation, Custom Zirconia Ceramics often become the only realistic way to meet performance, safety, and lifetime targets without constant redesigns.

At UPCERA, each component is designed to hold its shape and function under:

•Mechanical shock and vibration

•Frequent thermal cycling

•Long exposure to aggressive media

Where metallic parts may fatigue or slowly lose their geometry, zirconia tends to keep its dimensions. Where plastics may creep, soften, or age, Custom Zirconia Ceramics preserve the precision that your assemblies depend on.

Typical applications include:

•Sliding guides and linear bearing elements

•Rotating shafts, sleeves, and bushings

•Pump, valve, and sealing components in contact with abrasive or corrosive media

•Insulating and structural parts in high-voltage or high-frequency systems

In these positions, zirconia parts do more than "survive." By maintaining tight tolerances and smooth surfaces over long service lives, they support better process repeatability, cleaner motion, and more consistent product quality.

How UPCERA Designs and Manufactures Custom Zirconia Ceramics

UPCERA is not a reseller of catalog blanks. Our focus is on factory-direct Custom Zirconia Ceramics that start from your real application, not from a standard part number.

A typical project moves through several clear stages:

•Application review

We look at how the part is used today: loads, temperatures, media, cycle times, and failure modes of existing metal or polymer designs.

•Material and geometry selection

The right zirconia formulation is matched with a geometry that balances strength, manufacturability, and cost. Small changes - such as radius transitions, wall thickness, or shoulder design - often have a big impact on lifetime.

•Forming and precision machining

Advanced forming methods are combined with high-accuracy grinding or machining to reach the specified tolerances and surface finishes.

•Inspection and documentation

Each batch undergoes strict quality checks, with traceable measurements and documentation to keep performance consistent from lot to lot.

Because design, production, and inspection are all handled in one closed loop, UPCERA can support both small validation batches and stable large-scale orders of Custom Zirconia Ceramics using the same controlled processes.

Precision That Shows Up on the Shop Floor

Every engineer has seen the gap between CAD and reality. The drawing calls for tight tolerances; the box that arrives on the dock does not always match. Small errors in roundness, straightness, or diameter may look minor on paper but cause real trouble in demanding assemblies.

To address this, UPCERA applies tight process control and high-precision machining to Custom Zirconia Ceramics. Depending on the design, we can deliver:

•Lengths up to 300 mm

•Outer diameters up to 150 mm

•Surface roughness down to Ra 0.02-0.2 μm on key working surfaces

We also keep close control of wall thickness, concentricity, roundness, and perpendicularity so parts fit and move as intended. This level of detail is critical for:

•Bearings and bushings

•Valve and pump internals

•Positioning pins and alignment features

•Wear plates and guide rails

•Sensor housings, sleeves, and protection parts

For the end user, this shows up as smoother assembly, fewer surprises during installation, lower rejection rates, and more stable long-term operation. Properly specified Custom Zirconia Ceramics often outlast the metallic structures that hold them.

Designed for the Harshest Corners of Your Process

UPCERA's Custom Zirconia Ceramics are tailored for the harsh corners of industrial equipment where traditional materials simply cannot keep up. Zirconia parts bring:

•High fracture toughness to handle heavy loads and sudden mechanical shocks

•Exceptional wear resistance in high-speed, high-frequency, or high-friction motions

•Strong resistance to corrosive attack and heat-driven degradation

•Reliable electrical insulation with non-magnetic behavior for sensitive electronics and high-voltage assemblies

Because of this, Custom Zirconia Ceramics are especially well-suited for:

•Semiconductor tools - Low-particle, stable components for wafer handling, plasma processes, and cleanroom systems

•Aerospace and defense systems - High-precision parts that stay on tolerance through vibration, pressure cycling, and extreme temperature swings

•Robotics and automation - Guides, shafts, and structural elements that maintain alignment and limit unplanned stoppages for replacement.

- From Pilot Parts to Reliable Series Production

Adopting a new material is not just a technical question; it is also a supply question. Many companies succeed with a prototype run but struggle when they try to scale. Lead times grow, quality fluctuates, or documentation is incomplete.

As a factory-direct supplier, UPCERA structures its processes with long-term programs in mind. Our Custom Zirconia Ceramics are produced under consistent process control with documented inspection data and scalable capacity. The goal is not just to make a good first sample, but to keep the part stable over years of production and design changes around it.

Work with UPCERA on Custom Zirconia Ceramics

The real value of Custom Zirconia Ceramics appears when the material, geometry, and manufacturing route are matched to the actual working conditions. That is why UPCERA treats each project as a technical collaboration rather than a simple catalog order.

If you are dealing with recurring failures, high wear, corrosion, or unstable performance in crucial components, zirconia may be a practical way to break that pattern and stabilize your process.

Ready to see what Custom Zirconia Ceramics could do for your equipment?

Share your drawings, specifications, or current failure modes with the UPCERA engineering team. We will help you evaluate whether zirconia is appropriate, suggest realistic tolerances and surface finishes, and outline a clear path from prototype to dependable serial production.

Call to action: Contact UPCERA today to discuss your next Custom Zirconia Ceramics project and discover how our factory-direct support can help you build stronger, longer-lasting, and more reliable industrial systems.

English

English 中文

中文