Engineering Ceramics for Extreme Corrosion and Stress Loads

Engineering Ceramics give manufacturers a practical, low-risk path to reliability when equipment faces aggressive corrosion, high loads, and punishing temperature cycles. At UPCERA, we build for these exact realities: etch chemistries that eat metals, hot spots that warp substrates, bearings that seize under speed. Our promise is simple - longer life, tighter stability, fewer surprises on the line.

Why Engineering Ceramics Win In Tough Environments

Metal and polymer parts fail in predictable ways. They corrode in acids and plasmas, creep when temperatures spike, and drift out of tolerance after repeated heat-cool cycles. Each failure means unplanned stops, scrap, and missed delivery windows. Engineering Ceramics flip that script. Their crystal structures and chemical inertness resist attack; their stiffness and thermal stability protect geometry; their insulation preserves signal integrity. The result is steadier output and a lower total cost of ownership.

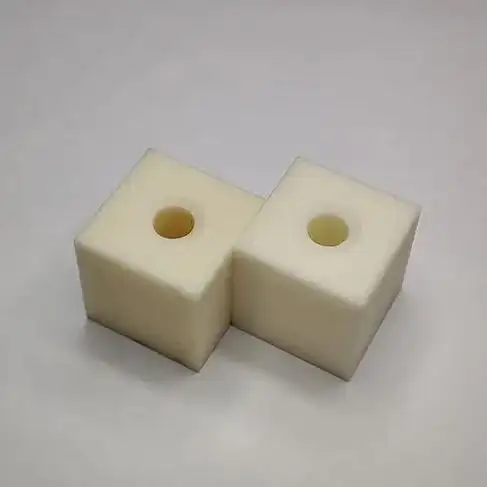

At the heart of many thermal bottlenecks is aluminum nitride (AlN). With thermal conductivity typically in the 70 - 200 W/m·K range, AlN moves heat away from dies and joints quickly, reducing gradients that crack solder or bend packages. Its low thermal expansion aligns with silicon, so assemblies stay flat and reliable through power cycling. Add high-temperature stability (up to ~2200 °C), low high-frequency loss, and plasma erosion resistance, and you get a substrate that thrives in RF, microwave, and high-power modules where heat and insulation must live together.

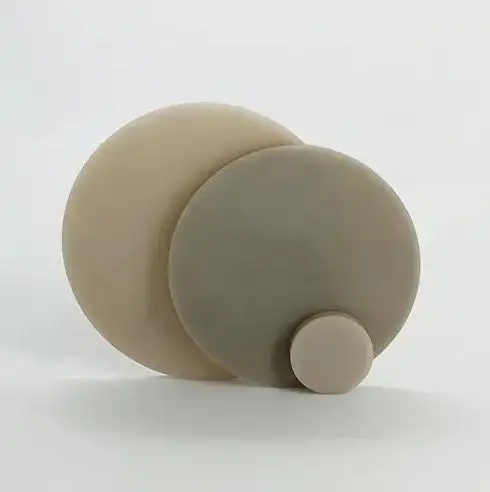

For moving parts and structural components, silicon nitride is the workhorse. This covalent-bonded ceramic pairs high strength with low density, which is perfect for lightweight, fast-rotating parts. It handles rapid temperature swings near ~1900 °C without cracking, and it resists wear, oxidation, and corrosive media - including molten metals and acidic solutions. Bearings, rotors, chucks, and hot-zone fixtures maintain surface finish and geometry for longer runs, even when speeds and loads increase.

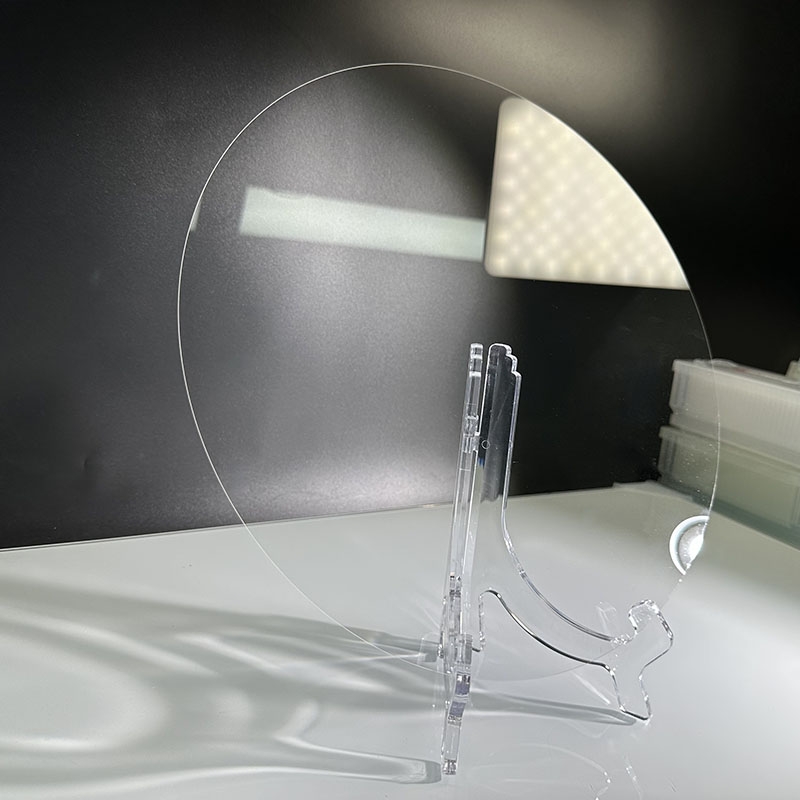

When the spec calls for purity and polish above all else, our 99.99% alumina answers. Ultra-high-temperature sintering drives atomic-level density and near-zero porosity, blocking intrusion from plasma, molten metal, and harsh chemicals. Its ultra-low dielectric loss and sub-nanometer surface smoothness support precision optics, quantum hardware, and advanced lithography - places where a tiny defect can ruin yield.

What Sets UPCERA Materials Apart

Our advantage is not one material but a system - powders, processing, machining, and metrology working together to protect your margin. UPCERA's R&D lineage traces to Tsinghua University's ceramics program, and our close collaboration with Sinocera strengthens control over raw materials and quality gates. That means fewer lot-to-lot surprises and faster scale-up once you approve a design.

- Aluminum Nitride: The Core Of Advanced Packaging

In power electronics and photonics, AlN is widely called the "core ceramic” for good reason.

- Heat spreader + insulator: Conducts heat efficiently (≈70 - 200 W/m·K) while maintaining electrical isolation

- CTE match to silicon: Reduces warpage and solder fatigue during cycling

- High-temp + plasma resistance: Fits etch/deposition tools and high-power substrates

- Low HF signal loss: Supports clean RF/microwave performance

Common use cases include high-power LED substrates, IGBT bases, RF interposers, and laser diode heat sinks - exactly where corrosion, heat, and stress collide.

- Silicon Nitride: Structural Reliability Under Load

When uptime depends on moving parts, Engineering Ceramics in silicon nitride keep lines running.

- Strength at lower mass: Lighter rotors and spindles with stiff, stable dynamics

- Thermal shock tolerance: Withstands fast ramps near ~1900 °C

- Wear and oxidation resistance: Performs in molten metals, acids, and high-speed contact

- Field-proven applications: Aerospace engine parts, precision bearings, etch hardware, biomedical components

- 99.99% Alumina: Purity, Smoothness, And Insulation

For extreme cleanliness and electrical performance:

- Atomic-level density: Blocks corrosive ingress; resists plasma and molten metal erosion

- Ultra-low dielectric loss: Preserves signal integrity in demanding electronics

- Sub-nanometer finish: Supports high-precision optics and lithography

- Biocompatible and non-magnetic: Useful for superconducting insulation and radiation-sensitive systems

Partnering With UPCERA: From Failure Modes To Scalable Parts

Selecting Engineering Ceramics is not only a material decision; it's a process choice. We begin by mapping your actual failure modes - corrosion rate, load spectrum, temperature profile, plasma chemistry, and time at condition. From there, we tailor microstructure, geometry, and finish to the job.

- For AlN packaging, we co-optimize thermal paths and dielectric integrity to tame hot spots without sacrificing isolation.

- For silicon nitride bearings or hot-zone components, we tune grain size and phase balance for fracture toughness and wear life.

- For 99.99% alumina optics and insulators, we control grain growth and polishing to achieve the finish and dielectric stability your device needs.

Our machining teams use CNC grinding, diamond tooling, and process sequencing designed to avoid microcracks that can seed failures under heavy stress. Metrology checks confirm tolerances and surface quality before parts leave the line, helping you qualify faster and ramp with confidence.

- Reduced downtime: Ceramics resist the chemistries and heat that take metal offline

- Longer service intervals: Stable geometry and surfaces extend maintenance cycles

- Cleaner signals and tighter fits: Insulation, low loss, and smooth finishes protect performance

- Lower lifetime cost: Fewer unplanned stops and higher yield outweigh a higher piece price

✅ Where Customers See The Biggest Wins

- Power modules and RF systems: AlN substrates move heat efficiently while preserving insulation and frequency response.

- High-speed equipment: Silicon nitride reduces rotating mass and wear, improving efficiency and service life.

- Extreme optics and electronics: 99.99% alumina protects signal integrity and surface quality, boosting yield in sensitive assemblies.

✅ Why UPCERA For Engineering Ceramics?

- Depth of portfolio: More than ten ceramic categories and thousands of product variants, ready for customization.

- IP and process control: Strong intellectual property and upstream powder control through Sinocera collaboration.

- Agile R&D: Fast design loops to break through technical barriers without sacrificing quality.

- Production discipline: Repeatable processes that shorten qualification and support volume manufacturing.

Closing Words

If your equipment fights corrosion, heat, or heavy loads, let's fix it at the material level. Share your environment, load case, and target lifetime, and UPCERA will recommend the right Engineering Ceramics - aluminum nitride, silicon nitride, or 99.99% alumina - then prototype quickly to prove the gain. Contact UPCERA today to reduce failures, extend service life, and stabilize output.

English

English 中文

中文