From Lab to Life: Practical Breakthroughs in High Performance Ceramics

High performance ceramics are no longer just a topic for scientists and engineers. These advanced materials are now stepping out of the lab and into our daily lives. Known for their strength, heat resistance, and durability, high performance ceramics are quietly transforming industries - from energy and electronics to healthcare and transportation.

But what makes these materials so special? And how are they changing the tools, devices, and systems we rely on every day? In this article, we'll explore real-world breakthroughs that bring cutting-edge science to practical use.

The Quiet Power of High Performance Ceramics

What Are High Performance Ceramics?

High performance ceramics are advanced materials designed for extreme environments. They offer excellent resistance to heat, wear, and corrosion. These ceramics also provide strong insulation and mechanical strength. They perform where traditional materials fail.

Why They Matter Now More Than Ever

Today's industries demand materials that can survive tough conditions. From 5G networks to electric vehicles and aerospace systems, high performance ceramics play a key role. Their durability and precision support faster, safer, and more efficient technologies.

From Lab to Life

Once used mainly in research, high performance ceramics are now critical in real-world applications. They help solve challenges in electronics, energy, and transportation.

Aluminum Nitride: Thermal Management's Unsung Hero

What Makes AlN Unique?

Aluminum nitride (AlN) stands out for its ultra-high thermal conductivity. It transfers heat quickly while remaining electrically insulating. It also has a low thermal expansion rate, which makes it stable when exposed to high heat. AlN resists chemicals, acids, and plasma corrosion.

Applications That Touch Our Daily Lives

AlN is used in many devices around us. It is the material behind high-power LED heat sinks, RF and microwave circuits, and power module bases. It plays a key role in 5G systems, automotive electronics, and semiconductor packaging.

How UPCERA Leads the Way

At UPCERA, we produce precision AlN ceramic parts for demanding environments. Our materials help manage heat in microelectronics and power systems. We ensure each product meets strict standards for thermal and electrical performance. As a trusted supplier, we help our partners build faster and more efficient technologies.

Silicon Carbide: The Cornerstone of Next-Gen Semiconductors

Unmatched Resilience in Harsh Environments

Silicon carbide (SiC) is known for its extreme hardness and thermal stability. It can withstand temperatures up to 2700°C and has excellent chemical resistance. It stays strong in high-radiation, high-voltage, and high-frequency conditions.

Critical for Power and Frequency

SiC is used in next-generation power devices. It is a core material for MOSFETs, diodes, and laser systems. It also appears in 5G base stations and electric vehicle power modules. Thanks to its wide-bandgap properties, SiC allows faster switching and lower energy loss.

Product Spotlight from UPCERA

We at UPCERA offer custom SiC ceramic parts for energy and high-frequency applications. Our SiC products are designed to handle extreme stress, heat, and voltage. They are ideal for cutting-edge power electronics and advanced industrial tools. We work closely with clients to ensure long-lasting performance.

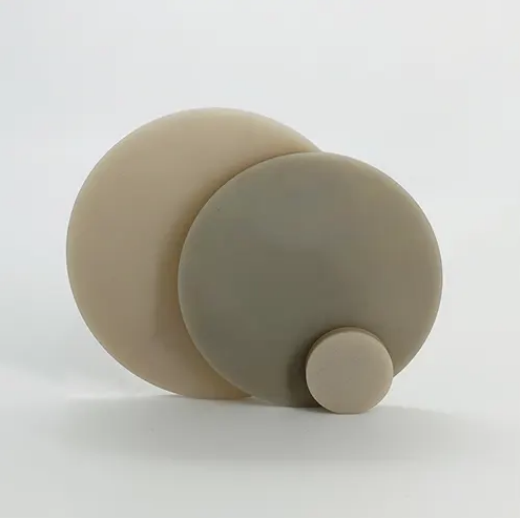

Silicon Nitride: The Structural Backbone of High-Stress Systems

Built For Shock And Speed

Silicon nitride is one of the most durable high performance ceramics. It has high fracture toughness and can resist sudden temperature changes. Its low density also helps reduce system weight. These properties make it reliable in high-speed and high-stress environments.

Ideal For Mission-Critical Systems

Silicon nitride is widely used in aerospace and automotive industries. It is found in engine components, bearing systems, and fuel injectors. It also supports semiconductor manufacturing and even biomedical implants. Wherever extreme heat and stress exist, silicon nitride is a trusted material.

UPCERA's Precision Ceramic Engineering

At UPCERA, we produce high performance silicon nitride parts with stable and precise quality. Our Si₃N₄ products are made to withstand tough environments. From aerospace to electronics, we help our customers achieve long-term reliability. We also offer customized machining to meet strict design needs.

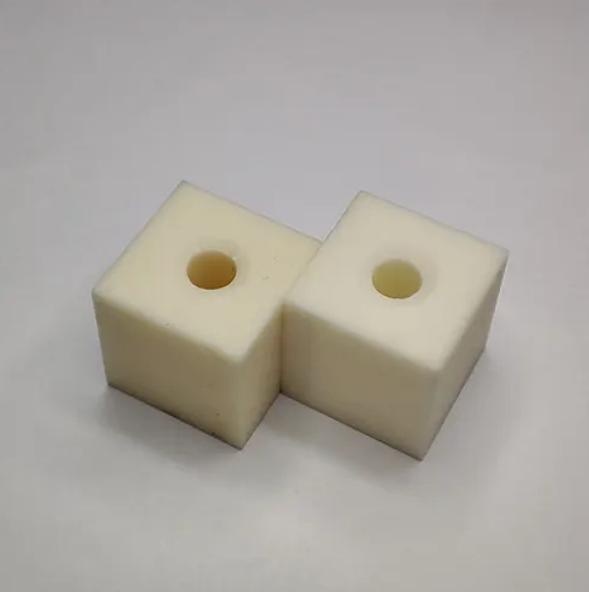

99.99% Alumina: Precision At The Atomic Level

Extreme Purity, Extreme Performance

This high purity alumina ceramic reaches 99.99% purity. It offers excellent insulation, sub-nanometer smoothness, and zero porosity. It also has very low dielectric loss and can perform under ultra-high temperatures or in vacuum environments.

Pinnacle Use Cases

Due to its high purity and stability, this ceramic is used in top-tier applications. These include quantum computing, deep-space shielding, and advanced lithography. It is also key in superconducting insulation and other cutting-edge technologies.

UPCERA's Technical Mastery

We at UPCERA specialize in producing ultra-pure alumina ceramics. Our processes ensure tight tolerance, mirror-like finishes, and chemical resistance. These materials are used in precision optics and high-end electronics. We are proud to support next-generation technologies with world-class ceramic solutions.

UPCERA: From Pioneer To Global Standard In Optical Ceramics

China's First Zirconia Ceramic Sleeve Innovator

UPCERA was the first company in China to develop zirconia ceramic sleeves for optical communication. From the start, we focused on independent R&D and strict quality control. This allowed us to break into a market once dominated by global giants.

A Reputation Built On Quality And Trust

Today, our materials help support cloud computing, AI infrastructure, and 5G networks. Quality, stability, and performance are our core strengths.

Forward-Looking Vision

As a manufacturer of high performance ceramics, we continue to innovate. We invest in new materials and smarter machining techniques. Our goal is to meet the rising demand for precision and durability in a fast-changing world. At UPCERA, we build ceramics for the future.

Choosing The Right Ceramic: FAQs And Industry Insights

Why Ceramics Over Traditional Materials?

High performance ceramics resist heat, wear, and corrosion better than metals or plastics. They are perfect for extreme conditions.

Where Are They Used Most Effectively?

They are used in aerospace, electronics, energy, and medical devices. Any industry that requires high precision and stability can benefit from ceramics.

Is Ceramic Machining A Barrier Or An Opportunity?

Though ceramics are hard and brittle, modern CNC and grinding methods allow precise shaping. UPCERA uses advanced machines to deliver top-quality custom parts.

Material Selection Tips For Engineers And Buyers

Choose materials based on the application:

- Use aluminum nitride for heat dissipation.

- Use silicon carbide for high-voltage systems.

- Use silicon nitride for moving parts.

- Use high-purity alumina for optics and insulation.

How Long Do Ceramics Really Last?

High performance ceramics can last for years or even decades. Their lifespan depends on the environment and application, but they generally outperform traditional materials.

What's Next In Ceramic Innovation?

Future trends include smarter materials, 3D-printed ceramics, and applications in AI and quantum computing. As technology grows, so will the need for better ceramics.

Partner with UPCERA for Precision Ceramic Solutions That Deliver

Ready to upgrade your technology with reliable, high-performance materials? At UPCERA, we deliver precision ceramic solutions trusted by industries worldwide. Whether you need thermal management, structural strength, or ultra-pure insulation, our products are built to perform in the most demanding environments.

Contact us today to discover how our high performance ceramics can support your next breakthrough.

In This Article

- 1 The Quiet Power of High Performance Ceramics

- 2 Aluminum Nitride: Thermal Management's Unsung Hero

- 3 Silicon Carbide: The Cornerstone of Next-Gen Semiconductors

- 4 Silicon Nitride: The Structural Backbone of High-Stress Systems

- 5 99.99% Alumina: Precision At The Atomic Level

- 6 UPCERA: From Pioneer To Global Standard In Optical Ceramics

-

7

Choosing The Right Ceramic: FAQs And Industry Insights

- 7.1 Why Ceramics Over Traditional Materials?

- 7.2 Where Are They Used Most Effectively?

- 7.3 Is Ceramic Machining A Barrier Or An Opportunity?

- 7.4 Material Selection Tips For Engineers And Buyers

- 7.5 How Long Do Ceramics Really Last?

- 7.6 What's Next In Ceramic Innovation?

- 7.7 Partner with UPCERA for Precision Ceramic Solutions That Deliver

English

English 中文

中文