How High Purity Ceramics Enable Atomic-Level Dense Structures

High Purity Ceramics are pushing advanced manufacturing far beyond what metals and conventional ceramics can handle today. Grains lock tightly together, leaving almost no pores and almost no path for heat, chemicals, or signals to leak. That sounds technical, but the impact is simple: devices become smaller, more stable, and far more reliable. In satellites, chip tools, and quantum labs, they quietly reset the limits of performance. So what exactly changes at the atomic level, and why does it matter so much?

From Raw Powder to Atomic-Level Density

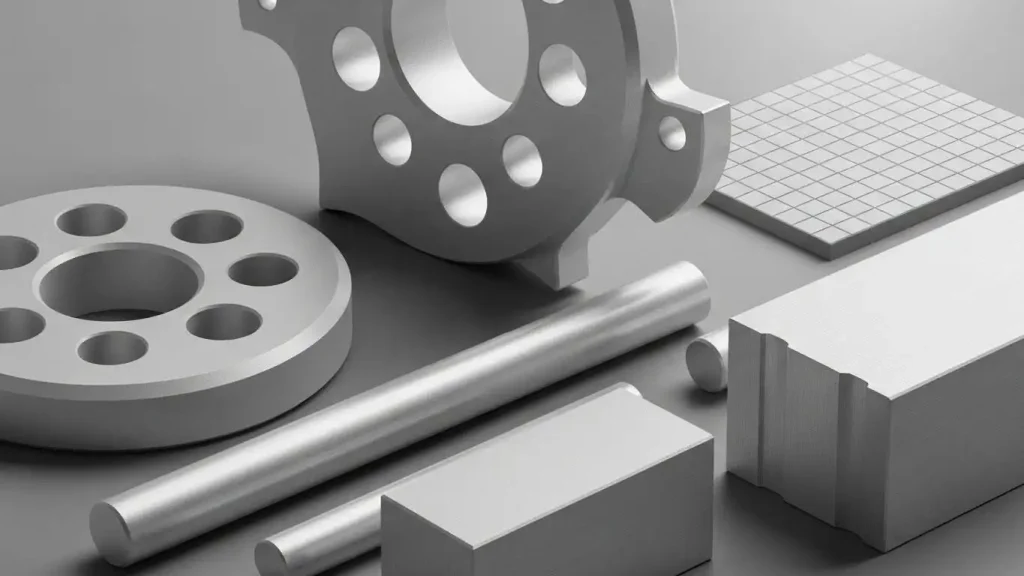

At UPCERA, when we talk about High Purity Ceramics, we mean something very specific: 99.99% alumina built on an ultra-clean ceramic matrix and fired at ultra-high temperatures under tightly controlled conditions. This is not just a small upgrade over standard ceramics. It is a different class of material.

In conventional ceramics, there are always tiny pores and impurities hiding between the grains. They may be invisible to the eye, but they are very visible in performance. Pores weaken the material, give corrosive media a way in, and increase dielectric loss. Over time, they become the starting point for cracks, leaks, and performance drift.

Our approach is to push those weak points out of the structure. By using ultra-high-purity alumina powder and a carefully engineered sintering process, we drive the material toward atomic-level dense structures. Grains pack tightly together, leaving almost no free space. The result is very close to a single, continuous solid with zero-porosity impermeability instead of a loose collection of grains.

This density is not just a nice material property on a datasheet. It turns into something engineers can feel in real projects: components that stay stable at high temperature, do not easily crack under thermal shock, and show consistent performance over long operating lifetimes. When a customer is building a deep-space probe, a semiconductor tool, or a quantum device, that reliability is not optional. It is the baseline.

Why Density and Purity Matter in Real Applications

1) Surviving Heat, Vacuum and Corrosive Media

Many of our customers come to UPCERA after running into the same set of problems:

• metal parts creeping or deforming at high temperature

• standard ceramics cracking after repeated thermal cycles

• plasma or molten metals slowly attacking chamber parts

• outgassing or contamination ruining ultra-clean environments

In deep-space probes, semiconductor lithography systems, or high-vacuum plasma equipment, components must handle a combination of high temperature, high energy, and very low pressure. This is where High Purity Ceramics start to show their full value.

• Ultra-high-temperature stability

In inert or vacuum conditions, UPCERA's high-purity alumina ceramics maintain their strength and shape at temperatures where many metals soften or react. This stability helps keep critical components dimensionally accurate over time.

• True impermeability

Because of the near-zero porosity, molten metals, aggressive chemicals, and plasma have almost no pathway into the material. That means less erosion, fewer leaks, and fewer unexpected failures inside process chambers.

• Hardness approaching single-crystal corundum

The extreme hardness improves wear resistance for sliding, rotating, or impact-prone parts. Precision stages, protection rings, and bearing components maintain their geometry longer, even in particle-rich environments.

For operators, these material advantages translate into very practical outcomes: longer maintenance intervals, more stable process parameters, and lower risk in systems where a single failure can cost millions in downtime or mission loss.

2) Protecting Signals, Not Just Structures

The story does not end with mechanical performance. Modern high-end systems are increasingly limited by noise, interference, and microscopic contamination rather than by simple strength.

In quantum technology, superconducting platforms, and advanced RF or microwave electronics, even tiny disturbances can kill performance. Outgassing from materials can change vacuum quality. Magnetic fields can disturb sensitive sensors. Dielectric loss can weaken or distort signals.

Here, High Purity Ceramics from UPCERA offer a combination that is especially valuable:

✅Non-magnetic, with negligible hysteresis effects

These ceramics can be placed close to superconducting magnets, qubits, or ultra-sensitive detectors without adding unwanted magnetic noise.

✅Chemically clean and biocompatible

The ultra-high purity and stable chemistry help minimize contamination from trace elements. This matters both in high-vacuum environments and in medical or life science instrumentation where cleanliness is critical.

✅ Ultra-low dielectric loss

In RF and high-speed electronic systems, low dielectric loss reduces signal attenuation and heat generation. That makes these ceramics well suited for high-frequency insulators, spacers, and precision connectors.

✅ Sub-nanometer surface smoothness

After precision finishing, functional surfaces can be made extremely smooth. This is essential for optical interfaces, precision motion components, and semiconductor lithography modules, where surface roughness directly impacts performance.

Because of this mix of properties, UPCERA's High Purity Ceramics have become key materials for radiation shielding layers in deep-space probes, insulating parts in superconducting systems, and critical substrates and carriers in semiconductor lithography and inspection tools.

Turning Advanced Material into Real-World Value with UPCERA

A high-performance material only creates value when it can be turned into stable, repeatable parts. That is where many engineering teams run into the next set of pain points.

Ceramics with very high hardness are, by nature, difficult to machine. Teams worry that their designs will be too complex to manufacture or that tight tolerances will disappear during sintering and finishing. Some common concerns we hear are:

"Can this thin wall survive both processing and operation?"

"Will we still hold micron-level flatness after sintering?"

"Can we keep sub-nanometer surface roughness on critical areas?"

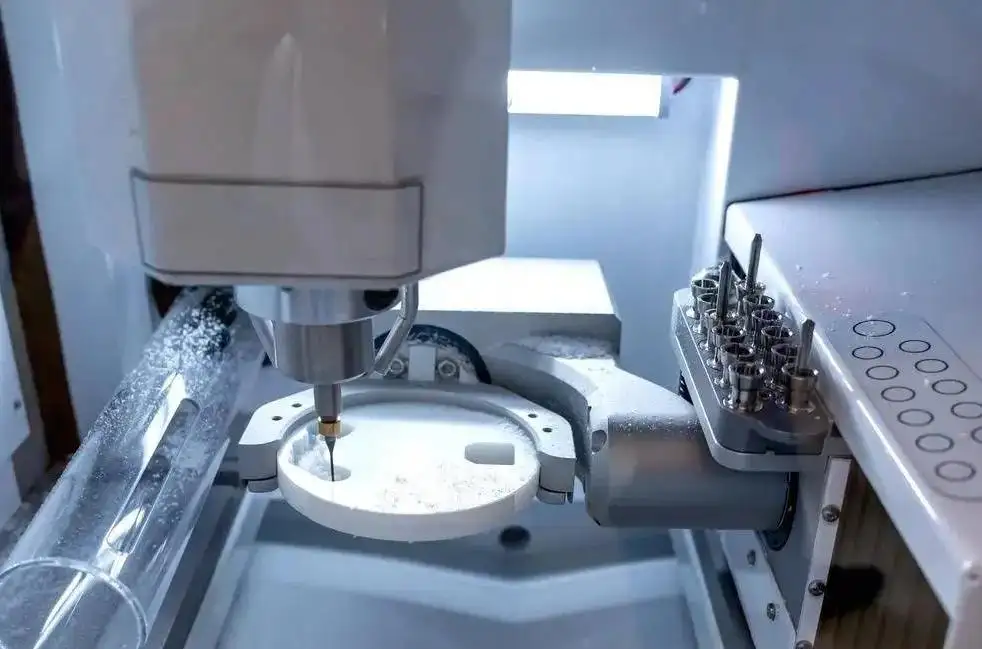

At UPCERA, we design our High Purity Ceramics with manufacturability in mind from the start. We combine:

• ultra-high-purity raw powder

• precisely controlled sintering curves

• advanced CNC machining and finishing technologies

This combination allows us to support thin-walled insulating components, complex three-dimensional structures for opto-electronic integration, and precision interfaces where micron-scale tolerances are required. Our engineering team works closely with customers to adjust geometries, select the right ceramic formulation, and plan processing routes that keep the design intent intact.

Durability is another recurring question. In many harsh-environment tools, customers want components that can run for years with minimal intervention. Precision ceramics are known for long lifetimes, and high-purity, dense structures push that advantage further. Under conditions involving high temperature, pressure, and corrosive media, UPCERA parts are designed to maintain performance over extended operating periods. In practice, replacing metal or polymer parts with High Purity Ceramics often reduces total maintenance cost and extends the service interval of critical assets.

Call To Action: Co-Engineer Your Next Breakthrough With UPCERA

If you are designing next-generation systems in quantum computing, semiconductor processing, aerospace, high-end optics, or advanced medical equipment, it may be time to rethink what your materials can do.

Instead of asking, "Can this component survive?" you can start asking, "What would my system look like if material limits were no longer the bottleneck?"

��� Talk to UPCERA about your challenge - whether it is temperature, vacuum, corrosion, signal integrity, or lifetime. We can help you:

- evaluate where High Purity Ceramics make the biggest impact

- choose the right material and geometry for your environment

- turn atomic-level dense structures into reliable, manufacturable parts

Reach out to UPCERA and explore how High Purity Ceramics can help you unlock the next level of performance in your products.

English

English 中文

中文