Why Industrial Ceramic Components Are Gaining Ground in Engineering

In recent years, industrial ceramic components have emerged as a game-changer in engineering. Their unique combination of strength, temperature resistance, and chemical stability makes them ideal substitutes for traditional metals. As industries push the boundaries of performance - from aerospace to data centers - these components deliver reliability under the toughest conditions. Today, we'll explore why ceramics are challenging steel, and how UPCERA, as an advanced manufacturer, plays a leading role in this revolution.

The Rise of Industrial Ceramic Components in Modern Engineering

The shift toward ceramics is not accidental. Engineers face harsher environments and higher performance demands. Traditional steel parts can corrode, deform, or wear out quickly under extreme heat, pressure, or corrosive chemicals. In contrast, ceramics maintain integrity at temperatures over 1,000 °C and resist most acids and alkalis. This resilience is driving their adoption across sectors:

• Aerospace: Thermal shields, turbine components, and wear-resistant seals.

• Electronics: Insulators, substrates, and components in 5G networks.

• Energy: High-temperature tubes and protective parts in power plants.

By combining low density with high hardness, industrial ceramic components reduce weight and extend equipment life. They also enable miniaturization in precision devices.

Key Properties That Outperform Steel

Industrial ceramic components offer several advantages over steel. Their performance profile includes:

✅ High Temperature Resistance

• Stable in environments above 1,200 °C

• No loss of mechanical properties at extreme heat

✅ Superior Wear and Corrosion Resistance

• Hardness exceeds 1,200 HV (Vickers)

• Inert to most chemicals and acids

✅ High Thermal Conductivity

• Efficiently dissipates heat in high-temperature environments

• Enhances performance and reliability of electronic components and sensors

✅ Lightweight Strength

• Density as low as 3.5 g/cm³ (alumina)

• Up to 40 % lighter than steel, reducing overall system mass

These properties translate into lower maintenance, longer service intervals, and higher uptime. They also open new possibilities where steel simply cannot perform.

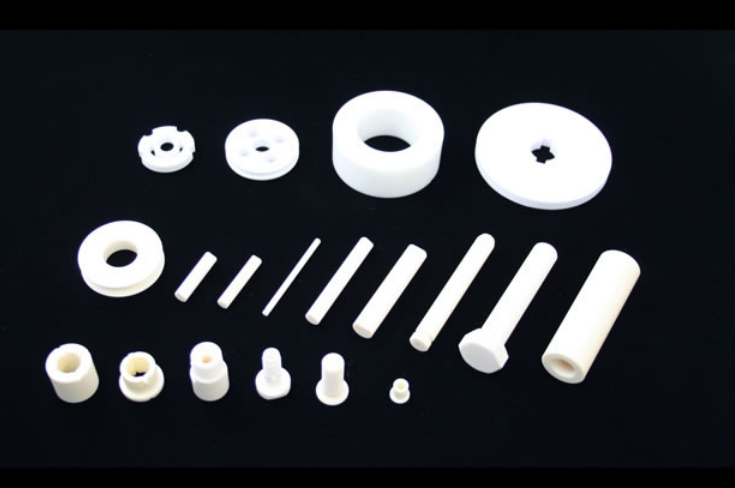

Core Products from UPCERA

At UPCERA, we leverage over 20 years of expertise to deliver top-quality industrial ceramic components. Our key offerings include:

✅ Ceramic Sleeves

• SC-type and LC-type standard sleeves

• Split and solid designs for fiber-optic connectors

• Micron-level tolerances ensure perfect mating

✅ Ceramic Tubes

• Materials: zirconia, alumina, silicon carbide

• Standard and non-standard sizes, custom lengths

• Ideal for fluid transport, thermocouple protection, insulation support

✅ Ceramic Ferrules

• High-purity zirconia construction

• Tight concentricity for optical performance

• Supports 5G, FTTx, and fiber laser systems

✅ Ceramic Rods

• Solid, hollow, stepped, and threaded designs

• Materials: alumina, silicon nitride, silicon carbide

• Used in bearings, probes, and insulation supports

✅ Custom Structural Components

• Complex geometries and extreme tolerances

• Bushings, nozzles, metallized parts, and special-shaped ceramics

• Perfect for aerospace, medical, and semiconductor industries

Our streamlined production lines ensure fast delivery and competitive pricing. Each part undergoes strict quality checks - from raw material inspection to final dimensional testing.

Applications Driving Demand

Across industries, the push for performance and reliability fuels the adoption of industrial ceramic components:

• 5G and Data Centers: Fiber-optic connectors rely on ceramic sleeves and ferrules for low-loss signal transmission. Our parts improve network uptime and reduce insertion loss.

• Semiconductor Manufacturing: Ceramic tubes protect sensors in plasma etching and CVD processes, resisting corrosive plasmas and high temperatures.

• Chemical Processing: Corrosion-resistant tubes and nozzles handle aggressive acids and bases. Customers report longer service life and fewer shutdowns.

• Aerospace and Defense: Thermal barrier components in jet engines and spacecraft use ceramics to withstand re-entry temperatures and extreme pressures.

• Medical and Diagnostics: Biocompatible alumina rods and tubes appear in imaging equipment and surgical tools, ensuring precision and safety.

As end-users demand higher uptime and lower lifecycle costs, industrial ceramic components become indispensable.

Manufacturing Excellence at UPCERA

We pride ourselves on process innovation and rigorous control:

• Advanced Material Selection: We source high-purity powders and develop tailored formulations for each application.

• Precision Molding and Sintering: Our presses and furnaces achieve uniform density and microstructure control.

• High-Precision Machining: CNC grinding delivers micron-level accuracy.

• Value-Added Processing: End-face polishing for ferrules, surface coatings, and metallization expand functionality.

We maintain lean workflows and continuous improvement practices. Real-time monitoring of sintering curves and automated inspection systems guarantee consistency and traceability.

Certification and Global Reach

Quality and compliance are at our core. UPCERA holds:

✅ ISO 9001 - Quality Management Systems

✅ ISO 14001 - Environmental Management

✅ ISO 45001 - Occupational Health & Safety

✅ REACH and RoHS - Chemical Compliance

These certifications reflect our commitment to safety, sustainability, and customer satisfaction. With distribution centers across Europe, North America, and Asia, we deliver solutions on time, every time. Our global partnerships ensure local support and rapid response.

Why Engineers Are Choosing Ceramics Over Metals

In many applications, ceramics now outperform metals - not just match them. Here's why:

✅ Wear resistance: No more worrying about friction or erosion.

✅ Thermal durability: Operate safely in temperatures where metals would fail.

✅ Longer lifespan: Reduced maintenance and lower replacement costs.

✅ Design flexibility: Customizable into complex shapes that metals can't match.

This is why industries from aerospace to semiconductors are shifting focus. Ceramics are not only stronger than steel in critical properties - they are smarter for long-term engineering success.

Final Thoughts

The momentum behind industrial ceramic components is undeniable. As engineers and product designers face stricter performance and environmental demands, ceramics are stepping into roles once dominated by metal and polymers. At UPCERA, we're proud to be shaping this transformation. Our ceramic technology is designed to empower next-generation industries with solutions that are reliable, efficient, and future-proof.

English

English 中文

中文