Why Industrial Sapphire Ceramic Parts Excel in Harsh Environments

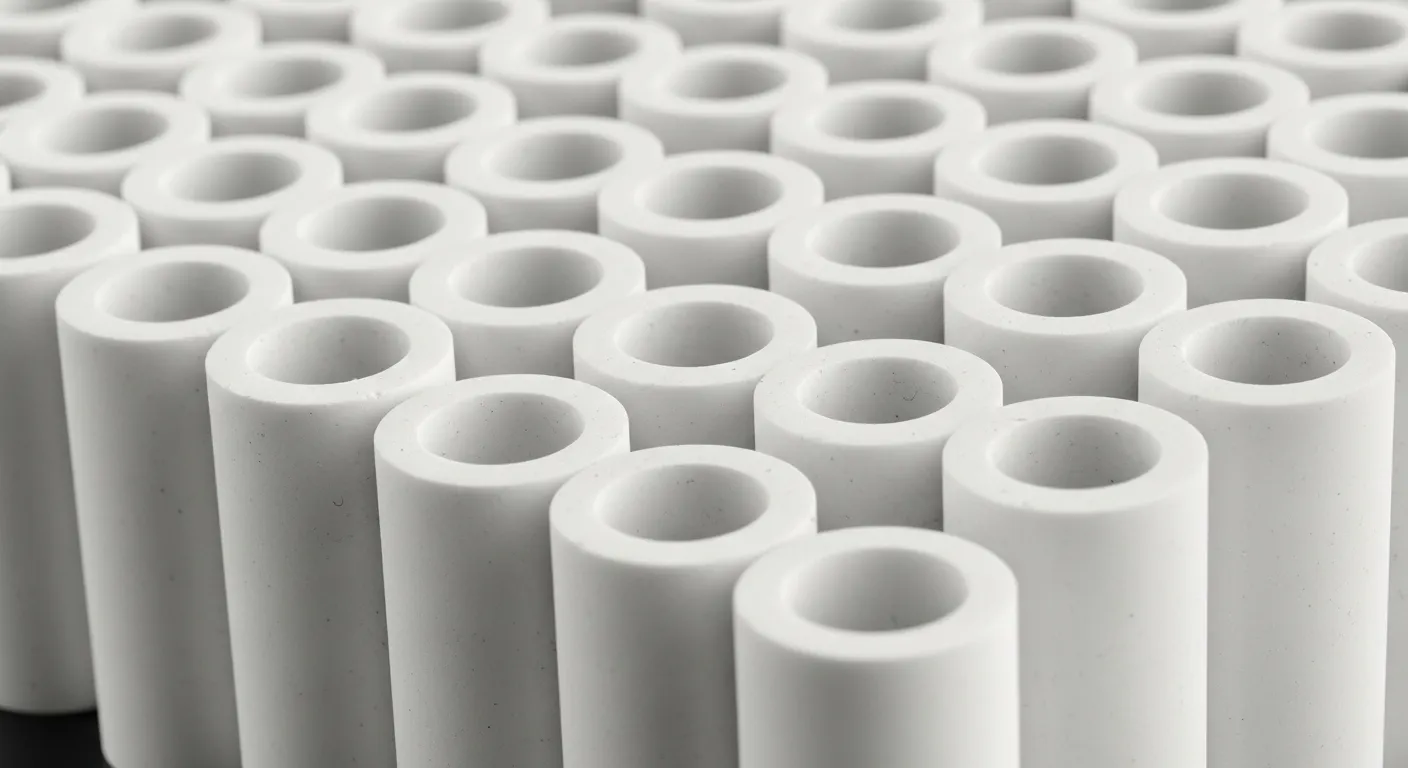

Industrial Sapphire Ceramic Parts are advanced components made from single-crystal sapphire. They look simple, but they are built for work that pushes ordinary materials to their limits. These parts are used in high-temperature systems, corrosive chemical lines, precision instruments, and optical equipment. They must survive heat, pressure, impact, and aggressive media without losing accuracy or strength. Many engineers now choose Industrial Sapphire Ceramic Parts when metal, glass, or standard ceramics start to fail. But what exactly makes them so durable in such harsh environments? And why can one material handle so many extreme tasks?

Why Industrial Sapphire Ceramic Parts Keep Working?

In real plants and labs, "harsh conditions" are rarely just one stress factor. A typical setup might combine rapid heating and cooling, fine abrasive particles carried by fluids, pressure pulses, corrosive media and long shifts of continuous operation. Metals can corrode, deform or creep. Standard ceramics may chip or develop microcracks that slowly grow into bigger failures.

Sapphire behaves differently. As a single-crystal form of alumina with a Mohs hardness of 9, it offers exceptional resistance to scratching and particle erosion. Industrial Sapphire Ceramic Parts keep their surface finish, edge quality and dimensional accuracy even after long exposure to abrasive flows or sliding contact. This helps maintain tight clearances, accurate alignment and clean sealing surfaces.

Temperature capability is another reason sapphire stands out. In suitable designs, sapphire maintains its core properties from cryogenic conditions around –200 °C up to approximately 2000 °C. That means the same material can be used in low-temperature detection systems, hot process windows, laser equipment or thermal processing tools where conventional metals may soften, oxidize or suffer distortion over time.

Chemical stability completes the picture. Sapphire is highly inert toward many acids, alkalis and solvents. In chemical processing lines, semiconductor equipment, analytical instruments or medical devices, this inertness helps reduce contamination risk and keeps performance more predictable over the full service life. Industrial Sapphire Ceramic Parts do not easily react with process media, so users see fewer gradual shifts caused by corrosion products or surface changes.

Unlike many technical ceramics, sapphire also offers optical clarity from the ultraviolet into the infrared. This unique mix of mechanical strength and optical transparency lets a single part act both as a rugged barrier and as a viewing or measurement window. In many designs, one well-engineered sapphire component can replace a fragile glass window plus a separate mechanical shield, simplifying assemblies and cutting the number of potential failure points.

How UPCERA Turns Sapphire into Practical Industrial Solutions

For UPCERA, choosing sapphire is only the first step. More than two decades of ceramic manufacturing experience have shown that long-term success comes from combining the right material with thoughtful engineering and disciplined process control.

- Starting from Real-World Problems

Most customers approach UPCERA because something in their current setup is not working as planned. Protective windows crack after thermal shock. Metal housings corrode when exposed to aggressive fluids. Sealing faces wear faster than expected. Optical ports scratch or fog during cleaning. Behind every failure is lost production, unplanned maintenance and, in some cases, safety worries.

UPCERA's engineers begin by mapping the full operating environment: temperature range and cycling speed, chemical exposure, mechanical loads, expected lifetime, cleaning procedures and any optical requirements. Using this information, the team proposes Industrial Sapphire Ceramic Parts with appropriate geometry, thickness, tolerances and surface finish. The objective is not just to "swap in sapphire," but to remove the root cause of the problem wherever possible.

- What Sets UPCERA's Production Approach Apart

To turn a design concept into stable, repeatable products, UPCERA follows a few core principles:

Factory-direct quality control - From selecting industrial sapphire blanks to final inspection, the full chain is controlled in-house. This supports consistent quality, dependable lead times and fast technical feedback when customers have questions.

Custom manufacturing capability - Many applications cannot use standard discs, tubes or rods. UPCERA produces tailored shapes, through-holes, countersinks, chamfers, sealing steps and precision-ground surfaces so that Industrial Sapphire Ceramic Parts drop straight into existing or new assemblies.

Application-specific surface preparation - Optical windows demand tight control of flatness, roughness and transmission. Mechanical parts place more emphasis on wear resistance, geometry and safe assembly. UPCERA adjusts grinding, polishing and cleaning procedures to match the part's real job.

As a result, UPCERA's Industrial Sapphire Ceramic Parts are used across demanding sectors including medical equipment, aerospace systems, precision machining and instrumentation. In these fields, the material's technical strengths turn into measurable improvements in uptime, consistency and overall equipment efficiency.

Where Industrial Sapphire Ceramic Parts Create the Most Value

Technical specifications only matter if they translate into business results. From UPCERA's project experience, sapphire-based solutions are especially valuable in three areas.

1. Longer Service Life and Less Downtime

When a nozzle, viewing port or bearing surface fails, the true cost is almost never limited to replacing a single part. Stopping a line often means cleaning, requalification, slow restart procedures and potential scrap. Repeated failures also eat into maintenance budgets and delivery reliability.

Because Industrial Sapphire Ceramic Parts resist wear, thermal shock and chemical attack, maintenance intervals can often be extended and unplanned stoppages reduced. Even though sapphire components frequently cost more than equivalent parts made from steel, glass or standard ceramics, the total cost over the life of the equipment often drops once replacement frequency and associated downtime are included.

In systems that move abrasive slurries, ultra-pure chemicals or high-temperature process gases, users frequently report fewer emergency shutdowns and more stable operating conditions after switching critical components to sapphire.

2. Stable Performance for Sensitive Measurements

In markets such as medical diagnostics, aerospace instrumentation and advanced manufacturing, measurement stability is not optional. Drift can mean wasted batches, mis-sorting, or failed qualification.

Here, Industrial Sapphire Ceramic Parts help by preserving surface quality and geometry under long-term exposure to heat, chemicals and mechanical contact. This can lead to:

•More consistent readings over months or years

•Better repeatability from batch to batch or between instruments

•Less drift caused by slow wear or corrosion of critical surfaces

For instance, a sapphire window on an optical sensor can keep its flatness and transmission long after a conventional glass window would have scratched, stained or become cloudy. The result is less time spent recalibrating, fewer false alerts, and stronger confidence in the quality of your data.

Cleaner, More Compact Designs

With sapphire, strength and optical clarity come in the same package. Designers no longer need a thin glass window supported by an extra metal guard. One durable sapphire component can do both jobs. This lowers part count, simplifies sealing, and reduces assembly steps, all while maintaining the toughness required for harsh service.

On top of that, Industrial Sapphire Ceramic Parts are well suited for high-purity gas lines, vacuum chambers, and other clean applications where outgassing, corrosion, or particle shedding must be minimized. That makes them attractive for semiconductor tools, analytical instruments and high-end research equipment.

Partner with UPCERA on Your Next Design

UPCERA aims to be more than a part supplier. The goal is to act as an engineering partner from first concept through validation and scale-up. If your equipment must cope with high temperatures, corrosive media, abrasive flows or demanding optical paths, UPCERA's team can help you evaluate where Industrial Sapphire Ceramic Parts make the most impact.

Together we can:

•Review current failure modes, maintenance pain points and operating conditions

•Propose sapphire component concepts that address the main risks

•Supply prototypes for trials and qualification

•Support smooth ramp-up once the design is proven in the field

If you are looking for practical ways to boost reliability in harsh environments, reach out to UPCERA's engineering team. Share your application details, and explore how Industrial Sapphire Ceramic Parts can help you cut unplanned downtime, stabilize performance and protect the long-term productivity of your equipment.

English

English 中文

中文