Premium LC Type Ceramic Sleeve Distributor

A premium LC type ceramic sleeve distributor is a fundamental partner for the modern data infrastructure. These distributors supply the core component that enables high-density fiber optic connectivity. The LC-type sleeve, built for the 1.25 mm ferrule, is the standard for data centers and telecom networks. A distributor's role is not just to sell these parts. It is to provide a fully-vetted, reliable, and consistent supply of a precision-engineered component. They are the quality-assurance link between massive-scale manufacturing and critical network assembly.

The demand for data continues to expand. This drives the need for more fiber connections in smaller spaces. The LC connector's success is a direct result of this. At the heart of every LC-to-LC connection is the small ceramic sleeve. Its quality dictates the performance of the entire link. Choosing a premium distributor ensures that this critical part meets the sub-micron tolerances required for high-speed data transmission.

What Is an LC Type Ceramic Sleeve?

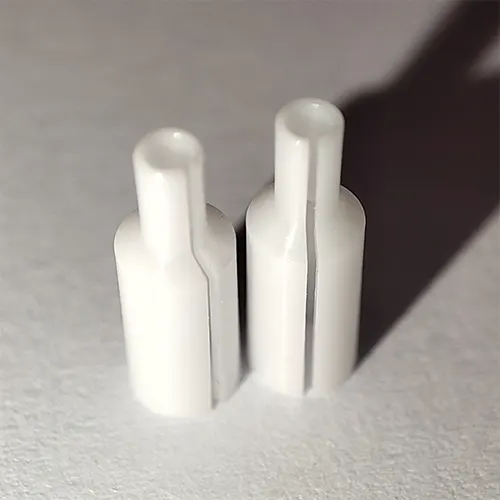

An LC type ceramic sleeve is a precision alignment component. It is a small, hollow cylinder. It is designed specifically for the LC (Lucent Connector) style of fiber optic connector. Its sole function is to accept two 1.25 mm ferrules and hold them in perfect, direct alignment. This allows light to pass from one fiber core to the other with minimal loss. The sleeve is the key enabling part inside every LC duplex or simplex adapter.

The 1.25 mm Ferrule Specification

The LC connector's design was revolutionary. It broke from the older 2.5 mm ferrule standard. The 2.5 mm standard was used by connectors like the SC, ST, and FC. The LC connector introduced a 1.25 mm ferrule. This new, smaller ferrule allowed the connector itself to be much smaller. It doubled the connection density on patch panels and equipment. The LC sleeve is, therefore, a component with a 1.25 mm inner diameter. This diameter is controlled to incredibly tight tolerances.

Material Science: Y-TZP Zirconia

These sleeves are not made from household ceramic. They are made from an advanced technical material. This material is Yttria-Stabilized Zirconia (Y-TZP). This specific material is chosen for a unique set of properties.

- Extreme Hardness: Zirconia is one of the hardest known materials. It is much harder than steel. This means it does not wear down, deform, or scratch after thousands of connections.

- High Fracture Toughness: This is zirconia's most important trait. Unlike other ceramics which are brittle, Y-TZP is very resistant to cracking. This is vital for the sleeve's design.

- Thermal Stability: The material's size does not change with temperature. A data center can have hot and cold aisles. The sleeve's dimensions remain constant.

- Smooth Surface: Zirconia can be polished to a mirror-like finish. This smooth inner surface prevents it from scratching or damaging the fiber ferrule end-face.

This combination of properties makes Y-TZP the only logical choice for a high-performance, high-reliability alignment sleeve.

The Split Sleeve Design

Most LC ceramic sleeves are "split" sleeves. They feature a single, narrow slit cut down the entire length. This slit is a deliberate engineering feature. It allows the hard zirconia sleeve to flex very slightly. When a ferrule is inserted, the sleeve compresses. This compression creates a gentle, consistent gripping force. This force holds the ferrule securely. It also accounts for tiny, sub-micron variations in ferrule diameter. It ensures a snug, perfectly centered fit for both ferrules, every time.

The Role of a Premium Distributor

A premium LC type ceramic sleeve distributor is not just a reseller. They are a critical supply chain partner. They provide value that goes far beyond simple order fulfillment.

Quality Assurance and Vetting

The quality of ceramic sleeves can vary greatly by manufacturer. A premium distributor's primary job is to be a quality filter. They perform the difficult work of vetting and auditing manufacturers. They maintain relationships with the world's best producers. These may be high-volume facilities that supply ceramic sleeves China or high-specification plants that produce ceramic sleeves Germany. The distributor invests in test equipment. They test incoming batches for dimensional accuracy and performance. They reject any part that does not meet their high standard.

Inventory and Supply Chain Management

The demand for LC connectors is massive and global. An assembly house or network installer cannot wait weeks for parts. A premium distributor holds a deep, local inventory. They stock millions of LC sleeves. This allows them to offer just-in-time delivery. Their customers can pull parts as needed. This reduces lead times from months to days. This inventory management is a critical service. It keeps production lines moving.

Technical Support and Expertise

A premium distributor has technical experts on staff. They understand the product at an engineering level. They can answer difficult questions.

- What is the standard concentricity of this sleeve?

- What is the insertion loss performance?

- Can you provide a sleeve for a custom adapter housing?

- Do these parts comply with Telcordia standards?

This expertise helps customers solve problems. It ensures they are using the right component for their application.

Documentation and Compliance

A professional distributor provides a full documentation package. This is a key part of their service.

- Certificate of Conformity (CoC): A document that proves the parts meet all stated specifications.

- Material Datasheets: Technical data on the Y-TZP material.

- Traceability: Batch and lot numbers for every shipment. This allows a part to be traced back to its origin.

- Compliance: Proof that the parts meet global standards like RoHS (Restriction of Hazardous Substances) and REACH.

This paperwork is essential for professional assembly and auditing.

Manufacturing and Quality Control of LC Sleeves

The 1.25 mm LC sleeve is a marvel of manufacturing. Its small size makes it more difficult to produce than its 2.5 mm counterpart.

The Manufacturing Process in Brief

- Formulation: Ultra-pure Y-TZP powder is mixed with a polymer binder.

- Molding: The mixture is heated and injection-molded into the "green part." This part is larger than the final sleeve.

- Debinding: The green part is slowly heated to burn away the binder.

- Sintering: The part is heated to over 1400°C. The zirconia particles fuse. The part shrinks to its final, dense, hard state.

- Lapping: The inner and outer diameters are ground and polished. This is a multi-stage process using diamond slurries to achieve sub-micron precision.

- Slitting: A diamond saw cuts the narrow slit.

- Inspection: Every sleeve is inspected.

The Challenge of the 1.25 mm Size

Manufacturing a 1.25 mm ID sleeve is an order of magnitude harder than a 2.5 mm SC sleeve. The lapping tools are smaller and more delicate. The part itself is more fragile. Holding a sub-micron tolerance on a 1.25 mm hole is a significant engineering feat. It requires state-of-the-art machinery and process control.

Critical Quality Metrics for LC Sleeves

A premium LC type ceramic sleeve distributor vets parts based on these key metrics:

- Inner Diameter (ID): This must be controlled to a tolerance of just a few microns. It is often specified as 1.250 +X/-0.000 mm.

- Concentricity: This is the most critical metric. It measures how centered the 1.25 mm hole is relative to the sleeve's outer wall. A low concentricity value (e.g., < 1.0 µm) is essential. Poor concentricity means the two fiber cores will be offset. This directly causes high signal loss.

- Outer Diameter (OD): This must be precise so the sleeve fits correctly inside the adapter housing.

- Surface Roughness: The inner wall must be polished to a very low Ra (roughness average). This prevents it from scratching the ferrule.

Advanced Metrology: How Sleeves Are Measured

A premium distributor cannot just "eyeball" a part. They use advanced metrology tools to verify quality.

- Air Gauges: This is the standard for checking the ID. A precise amount of air is blown through the sleeve. The system measures the back-pressure. This calculates the ID to sub-micron accuracy.

- Laser Micrometers: These non-contact tools scan the OD.

- Video Inspection Systems: High-resolution cameras with special lighting check for concentricity. They also look for micro-cracks, chips, or other visual defects.

Performance Testing: Insertion Loss (IL)

The final test is how the sleeve performs. A distributor will take sleeves from a batch. They will build them into standard adapters. They measure the Insertion Loss (IL). This is the amount of signal (light) lost at the connection point. A high-quality LC sleeve will contribute to a very low insertion loss. This is often below 0.2 dB.

Comparing LC Sleeves to Other Standards

The LC sleeve and its 1.25 mm ferrule defined an era. It displaced the older, larger 2.5 mm standard.

LC (1.25 mm) vs. SC (2.5 mm)

The key difference is density. An LC connector has roughly half the footprint of an SC connector. This means you can fit twice the number of connections in the same 1U rack panel. This high-density is the reason the LC connector is the king of the data center. The 2.5 mm SC sleeve is still a major component. It is used in telecom and other applications. A distributor must understand the supply chain for both, including sources like sc-type-ceramic-sleeve-china.

The High-Density Revolution

The LC connector's dominance is most visible in SFP transceivers. The SFP (Small Form-factor Pluggable) transceiver is the standard module for network equipment. The SFP port was designed around the LC connector. This partnership cemented the LC's role for decades. Every SFP, SFP+, and SFP28 module that uses duplex fiber has an LC port. This means they rely on the 1.25 mm ceramic sleeve.

Beyond LC: New Connector Types

Newer, even smaller connectors now exist. These include the CS and SN connectors. These are designed for the next generation of 400G and 800G transceivers. However, the LC connector's installed base is massive. It will remain the dominant connector for single-fiber and duplex-fiber links for many years. The demand for LC sleeves is stable and strong.

How to Select the Right LC Type Ceramic Sleeve Distributor

Choosing a partner is a critical decision. A good distributor is a partner. A bad distributor is a liability.

Key Questions to Ask Your Distributor

When you evaluate a potential LC type ceramic sleeve distributor, you must ask specific questions.

- "What is your manufacturer vetting process?" A good distributor will explain their auditing, inspection, and testing process.

- "Are you ISO 9001 certified?" This is a baseline for a quality-focused company. An ISO 9001 certification from a body like the International Organization for Standardization (ISO) shows they have a documented quality system.

- "Can you provide full traceability and a CoC with every shipment?" The answer must be "yes."

- "What are the typical ID and concentricity tolerances of your LC sleeves?" They should be able to give you an exact technical specification (e.g., "Concentricity is guaranteed < 1.0 µm").

- "What are your stock levels and typical lead times for X million pieces?" This tests their capability as a supply chain partner.

Red Flags to Watch For

- Vague Answers on Quality: If a distributor cannot give you a hard specification, they do not truly know their product.

- No Certifications: Lack of an ISO 9001 certification is a major red flag.

- Unusually Low Prices: A price that is far below the market average is a strong indicator of a poor product. It likely means they are using low-grade zirconia, or they are skipping the 100% inspection process.

- No Technical Support: If you cannot speak to someone who understands the product, you are not dealing with a premium distributor.

Understanding International Standards

A good distributor is fluent in global standards. They understand that LC connectors are defined by bodies like the International Electrotechnical Commission (IEC). The standard IEC 61754-20, for example, defines the LC connector family. The distributor ensures their sleeves allow assemblers to build connectors that meet or exceed these standards. A good ceramic sleeves guide can help explain these details.

Conclusion: The Value of a Premium Distributor

The LC type ceramic sleeve is a tiny, inexpensive component. It is easy to overlook. But it is one of the most important parts of a modern network. A single bad sleeve can cause a link to fail. That failed link can take down a server, a switch, or an entire data hall.

A premium LC type ceramic sleeve distributor understands this. They take on the critical responsibility of quality assurance. They invest in the tools, people, and inventory. We do this so that their customers can build reliable networks with confidence. They are not just selling a part. They are selling consistency. In the world of high-speed data, that is the most valuable service of all.

English

English 中文

中文