Expanding Uses for Machinable Ceramic Rod in Design

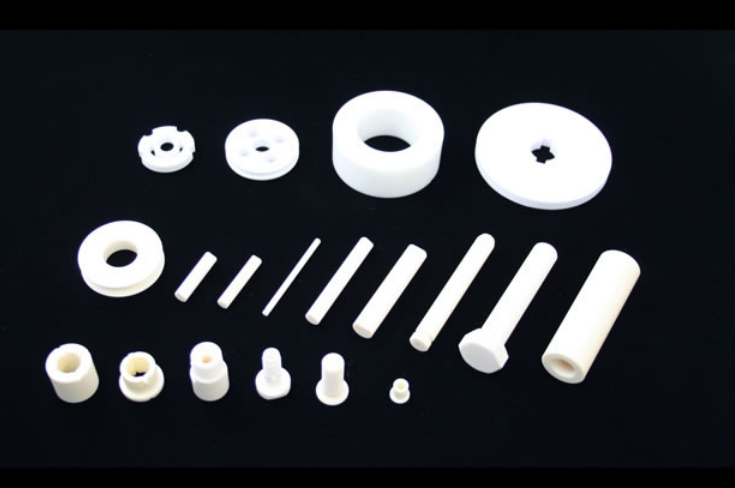

Machinable Ceramic Rod is redefining how engineers solve wear, heat, and insulation challenges across demanding industries. At UPCERA, we see customers replace metal or polymer parts with zirconia- and alumina-based solutions to gain longer life, tighter tolerances, and safer operation. Below, we share what's changing, where the new value appears, and how to specify rods that deliver results in real production.

Why New Uses Are Emerging for Machinable Ceramic Rod

Metal parts struggle with abrasive media, corrosive chemistries, and thermal cycling. Polymers can't hold shape at high temperatures. The result is unplanned downtime, drifting tolerances, and recurring maintenance spend. Machinable Ceramic Rod materials now bridge this gap by combining strength, wear resistance, and electrical insulation in one stable, clean solution.

From UPCERA's manufacturing floor, the shift is clear. Teams are adopting ceramic rods as structural components, guide pins, and insulation parts in both mechanical and electronic systems. They withstand high-temperature gas or liquid flow, protect delicate assemblies as sleeves, and serve as precision pipe fittings in corrosion-resistant lines. When engineers need dimensional stability plus safety near high voltages, ceramics win - quietly and reliably.

Material Foundations: Zirconia and Alumina

Zirconia and alumina are premium technical ceramics with consistent microstructures. They are chosen for their high strength, fracture toughness, and stability under heat.

✅ High strength and fracture toughness for reliable service life

✅ Excellent wear and corrosion resistance in abrasive or chemical media

✅ Thermal and electrical insulation for safer systems and cleaner signals

✅ Smooth surface and tight tolerances to reduce friction and leakage paths

✅ Custom production available to match unique geometries or assembly stacks

These features unlock uses that metals and polymers can't cover, especially where purity, non-magnetic behavior, or low particle generation are required.

New Application Scenarios Transforming Design and Maintenance

As processes evolve, engineers are deploying Machinable Ceramic Rod materials in places that used to eat parts for breakfast. We see three patterns:

1) Reliability upgrades in flow and protection.

Plants are inserting ceramic rods as protective sleeves and precision pipe fittings in high-temperature or corrosive pipelines. The goal is longer intervals between shutdowns and stable dimensions despite thermal spikes. When acids, alkalis, or hot gas erode conventional parts, ceramics keep their form.

2) Precision and safety in electrical environments.

Electronics and power systems use ceramic standoffs, spacers, and insulators to maintain creepage distances while resisting heat. The result is fewer failures from carbonization or deformation, and safer separation of conductors in compact designs.

3) Clean, durable interfaces in motion systems.

Industrial machinery adopts ceramic guide pins, shafts, and rollers to cut wear and keep alignment steady. Less debris, smoother surfaces, and predictable tolerance retention translate into better product yield and fewer line stoppages.

These same advantages extend to medical and laboratory instruments, semiconductor wafer handling, aerospace and automotive assemblies, and scientific fixtures where purity and repeatable tolerances are non-negotiable.

• Dimensional Precision and Surface Finish Unlocks Upgrades

Engineers often ask, "Can ceramics hit my fit requirements?” With UPCERA, the answer is yes - and repeatably.

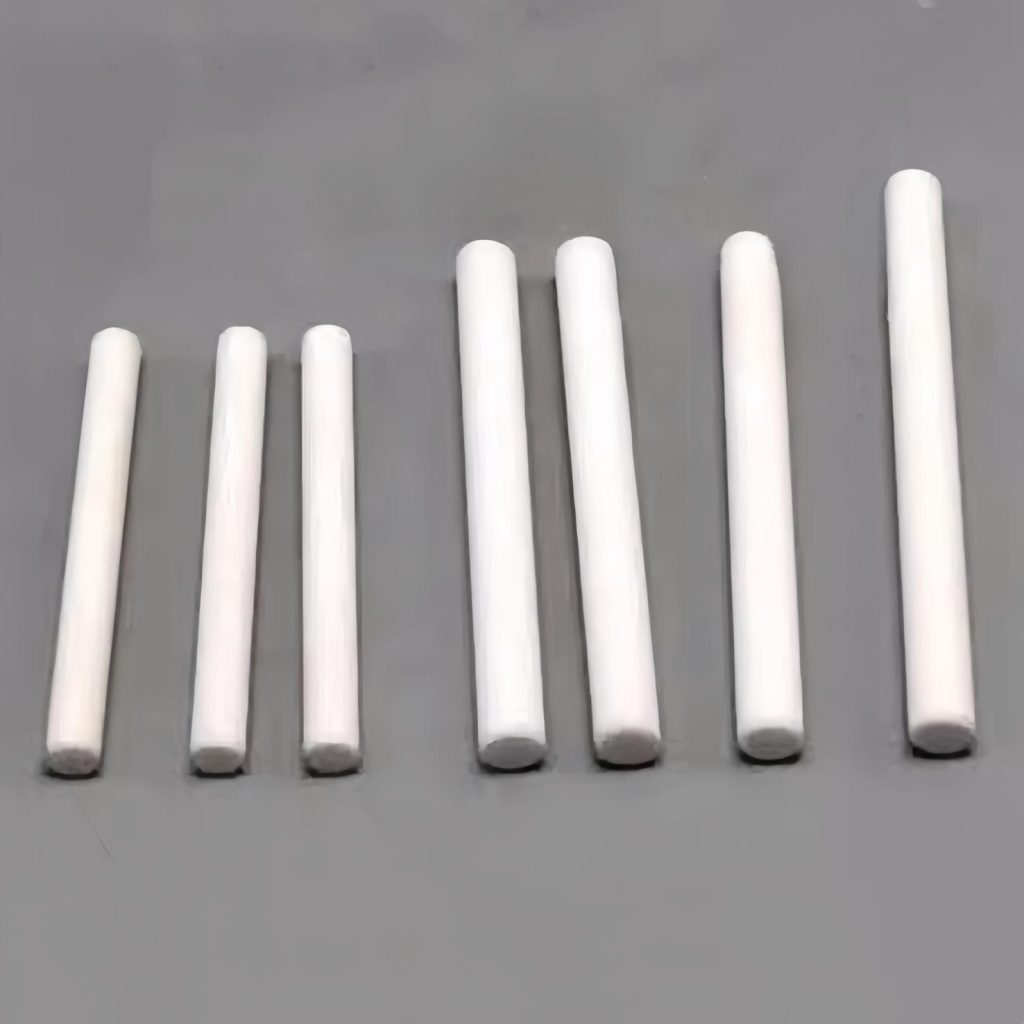

✅ Length: up to ≤ 1000 mm

✅ Outer Diameter: up to ≤ 150 mm

✅ Minimum drilled hole: ≥ φ0.4 mm

✅ Outer diameter precision:

• 1-25 mm: ± 0.002 mm

• 20-50 mm: ± 0.003 mm

• 50-100 mm: ± 0.050 mm

• 100-150 mm: ± 0.100 mm

✅ Length/Thickness precision: ± 0.005 mm

✅ Surface roughness: Ra 0.03

These numbers make retrofits practical. You can hold alignment in a hot zone, maintain seal integrity in harsh media, and keep electrical spacing exact - without constant rework.

Why UPCERA Is the Partner of Choice - and How to Get Started

Selecting a Machinable Ceramic Rod is not just a material decision - it's a manufacturing partnership. UPCERA supports standard and custom specifications, from prototype trials to volume production, with process controls that protect tolerances and surface quality. Our application engineers help translate field pain points - wear scars, heat distortion, creeping leakage - into targeted ceramic designs that drop into existing assemblies.

• Product Snapshot: Machinable Ceramic Rod by UPCERA

✅ Delivers high mechanical strength and hardness to resist bending, wear, and impact

✅ Performs reliably under high temperatures, maintaining dimensional stability

✅ Corrosion and chemical resistance for acids, alkalis, and aggressive media

✅ Excellent electrical insulation with high dielectric strength

✅ Maintains dimensional accuracy over time thanks to low thermal expansion

✅ Safe for sensitive environments - non-magnetic, inert, cleanroom friendly

✅ Smooth surface and tight tolerances for low friction and precise fits

✅ Custom production available to meet your geometry and assembly stack

Call to Action

Ready to replace short-lived metal or polymer parts? Share your drawing and operating conditions with UPCERA. We will recommend the right zirconia or alumina Machinable Ceramic Rod specification, validate tolerances, and provide a fast quote. Whether you need a precision machinable ceramic rod supplier or are qualifying a zirconia machinable ceramic rod for high-temperature pipelines, our team is ready to help you design in durability. Let's extend service life, cut maintenance, and stabilize quality - part by part. Contact UPCERA today to review your application and sample plan.

English

English 中文

中文