Custom Ceramics for Every Industry

Innovative ceramic solutions customized for precision, durability, and performance across aerospace, electronics, medical, and industrial sectors.

* THERE ARE 73 ARTICLES

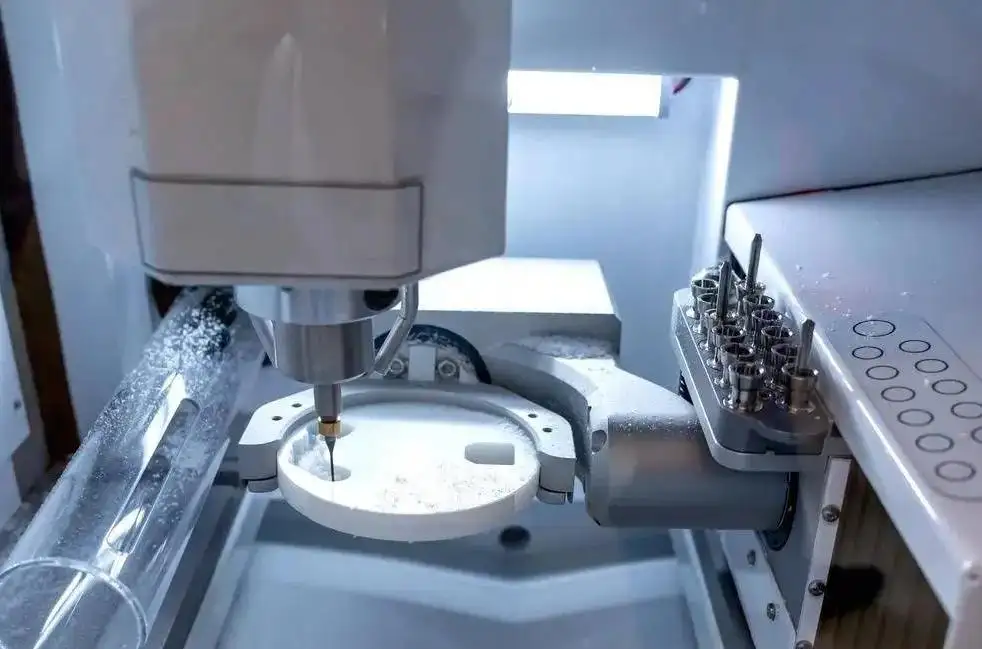

How Custom Ceramic Machining Tackles Tight-Tolerance Challenges

Custom Ceramic Machining turns hard, brittle ceramics into precise, functional parts. It means shaping, drilling, grinding, and polishing high-purity materials to tight tolerances. Think zirconia, alumina, silicon carbide. These parts ...

By admin

2025-11-07

2025-11-07

How CNC Ceramic Machining Improves Precision in Tough Materials

CNC Ceramic Machining uses computer-controlled tools to shape ultra-hard ceramics with high accuracy. It turns zirconia, alumina, silicon nitride, and silicon carbide into precise parts with clean surfaces. These parts ...

By admin

2025-11-06

2025-11-06

Solving Battery Overheating with High Purity Alumina Components

High Purity Alumina Component design sits at the center of cooler, safer battery systems - quietly managing heat while protecting high-voltage pathways. At UPCERA, we specialize in custom machining and processing of ...

By Admin

2025-10-23

2025-10-23

Zirconia Structural Components for Extreme Environments

Zirconia Structural Components keep machines alive when heat, friction, and corrosive media attack. They resist wear. They stay stable under sudden temperature shifts. They insulate where metals conduct. In labs ...

By Admin

2025-10-23

2025-10-23

Stop Frequent Replacements with Durable Advanced Ceramic Valve Disc

Advanced Ceramic Valve Disc technology turns chronic valve failures into predictable, low-touch operation. Plants in water treatment, chemicals, and power generation often live with leakage, drift, and unplanned stoppages that quietly ...

By Admin

2025-10-23

2025-10-23

Custom Ceramic Insulators vs. Standard Parts: Which Performs Better?

Custom Ceramic Insulators change the math when equipment runs hot, corrosive, or electrically intense. We see the gap on real lines, not just in specs. Uptime, yield, and safety hinge ...

By Admin

2025-10-23

2025-10-23

English

English 中文

中文