Small but Mighty: A Precision Ruby Nozzle for Industrial Equipment

In modern manufacturing, even the smallest part can make a big difference. One such part is the precision ruby nozzle for industrial equipment. It may look tiny, but its impact is huge. From 3D printing to high-pressure cleaning, this little nozzle is showing up in more and more machines.

Why ruby? Why now? And what makes this nozzle stand out from metal or ceramic alternatives? Many experts believe it's the key to improving speed, accuracy, and durability - all in one. But is it really worth the switch?

In this article, we'll explore the surprising power behind this small component. You might just rethink what's driving your equipment's performance.

Why Size Isn't Everything

The Hidden Power of Precision Parts

In industrial equipment, every part matters. Some of the most important components are also the smallest. One such part is the precision ruby nozzle for industrial equipment. Though small in size, it plays a big role in performance.

Introducing the Precision Ruby Nozzle for Industrial Equipment

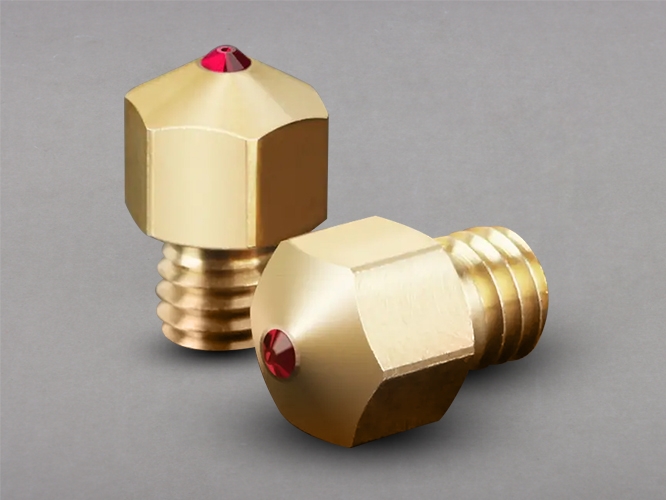

The ruby nozzle is not just a piece of hardware. It is made with advanced materials that can handle extreme conditions. It provides smooth flow, high wear resistance, and long-term durability. These qualities make it ideal for high-precision work.

The Science Behind the Strength

What Is a Ruby Nozzle Made Of?

The precision ruby nozzle for industrial equipment is made from synthetic ruby. Ruby is a single crystal of aluminum oxide, doped with chromium. It looks beautiful but performs even better.

Key Properties: Hardness, Heat Resistance, Inertness

Ruby is incredibly hard - ranking 9 on the Mohs scale. It resists scratches and wear over time. It also withstands high temperatures, up to 2050°C, and does not react easily with chemicals. This makes it stable and safe for long-term use in harsh environments.

Why Ruby Crystals Are Strategic Functional Materials

Because of these qualities, ruby is called a "strategic functional material.” It is used in lasers, precision instruments, and advanced machinery. In industrial nozzles, it ensures long life and reliable performance.

The UPCERA Precision Ruby Nozzle

Meet the Product: A Small Gem with Big Capabilities

At UPCERA, we have developed a precision ruby nozzle for industrial equipment that combines strength and accuracy. It may be small, but it handles big challenges. Our nozzle supports stable flow, even under high pressure or heat.

What Sets It Apart from Metal and Ceramic Alternatives

Compared to metal or ceramic nozzles, ruby offers much higher wear resistance. It also has a smoother surface, which reduces friction. This leads to less energy loss and better control. The result? Higher precision and less maintenance over time.

Built to Last: Stability, Durability, Precision

Our ruby nozzles are made for lasting performance. They resist corrosion and maintain shape even after long use. The tight tolerances help keep systems running smoothly. Whether it's fluid control, high-speed cutting, or precision spraying, our nozzle delivers reliable results.

Application Scenarios: Where Precision Matters Most

Industrial Equipment: From CNC to 3D Printing

The precision ruby nozzle for industrial equipment is used in many fields. In CNC machining, it supports fine cutting and smooth coolant flow. In 3D printing, it helps maintain exact temperature and material flow. These tasks demand tight tolerances. Ruby nozzles deliver them.

Fluid Control, High-Pressure Cleaning, and Beyond

Ruby nozzles also work well in fluid control systems. They handle both gas and liquid under pressure. In high-pressure cleaning, they resist abrasion from harsh chemicals and strong water jets. Unlike metal nozzles, they keep their shape and performance longer.

Case Example: Performance Under Extreme Conditions

In one case, a factory using high-speed spraying replaced metal tips with ruby nozzles. Downtime dropped. Cleaning became easier. The nozzles lasted much longer. In rough industrial settings, precision ruby nozzles for industrial equipment prove their value every day.

Inside The Engineering Of UPCERA

How UPCERA Designs for Precision

At UPCERA, we take pride in every part we make. Our team studies every detail. For each precision ruby nozzle for industrial equipment, we ensure smooth bore design, low friction, and perfect fit. Every step follows strict quality rules.

Customization and Tight Tolerance Capabilities

We support custom sizes and features. Whether customers need longer life, tighter holes, or special shapes, we respond quickly. Our advanced tools help us meet micro-level tolerances. That means better accuracy and more control.

Built with Purpose: Smooth Bore, Low Friction, High Stability

Each ruby nozzle is made with clear goals - long wear life, clean fluid output, and stable operation. These features come from our deep experience in ceramics. That includes our expertise in zirconia ceramic ferrule, another key product in our line.

Why Choose UPCERA? A Trusted Name In Advanced Ceramics

A Pioneer in Ruby Ceramics

We are proud to be a pioneer in advanced Ruby Ceramics. Today, we are a global supplier trusted in industries from telecom to precision machinery.

From Tsinghua Innovation to Global Market Recognition

Our roots go back to Tsinghua University's materials research. We use this strong base to build products that lead the market. Our precision ruby nozzle for industrial equipment reflects this deep technical strength.

Quality First: Manufacturing, IP, and R&D Collaboration

We hold strong IP rights and work closely with leading partners like Sinocera. This helps us control product quality from raw material to final piece. We also invest in fast R&D cycles to meet new customer needs.

Benefits In The Real World

Long Lifespan, Low Maintenance, High ROI

A precision ruby nozzle for industrial equipment does not wear out quickly. It resists corrosion and surface damage. That means fewer replacements and lower costs. Over time, it brings a clear return on investment.

Reliable Performance in Harsh Operating Environments

Whether it's high temperature, strong pressure, or chemical contact, ruby stays stable. That's why industries choose it for sensitive or heavy-duty tasks. From metal cutting to data center cooling, it stays reliable.

Compatible with Modern Industrial Needs

Today's machines demand more from their parts. Small errors can lead to big problems. Our nozzles and zirconia ceramic ferrules meet modern demands for accuracy, durability, and speed. With UPCERA, your systems are ready for the future.

Boost Durability and Accuracy with UPCERA's Ceramic Solutions

The precision ruby nozzle for industrial equipment may be small, but its impact is powerful. With exceptional hardness, heat resistance, and stability, it meets the toughest industrial demands. Backed by UPCERA's deep expertise and advanced ceramic technology - including our trusted precision ruby nozzle for industrial equipment - this nozzle delivers long-term value and reliable performance. For businesses seeking precision, durability, and innovation, UPCERA offers the solutions to lead in today's competitive market.

English

English 中文

中文