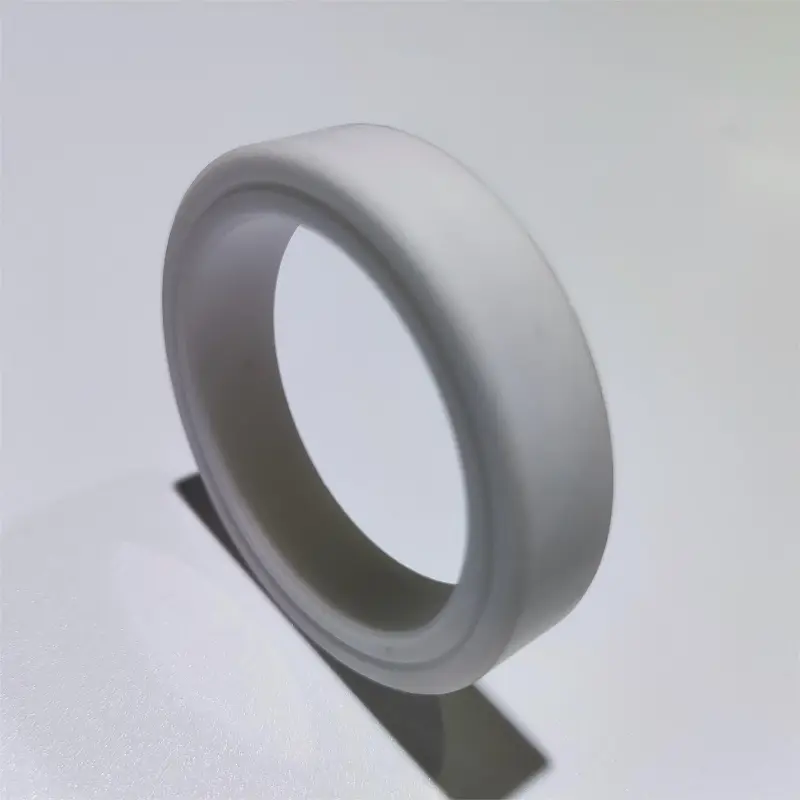

Alumina Ceramic Ring

Alumina ceramic ring is made of high-performance ceramic, featuring excellent high-temperature resistance, wear resistance, corrosion resistance, and high strength. Widely used in fluid transport, temperature protection, insulation support, and chemical equipment. We offer zirconia, alumina, silicon carbide, and silicon nitride in various sizes, with precision machining and custom structures to meet diverse needs.

- High temperature resistance & high strength – Suitable for high temperature conditions above 1000°C, long-term stable operation.

- Excellent corrosion resistance & insulation performance – Suitable for high acid and alkali, chemical fluid pipelines and electrical insulation applications.

- High-precision processing – Up to ±0.002mm, surface roughness Ra0.05 (specific accuracy depends on shape & material, see technical specifications below for details).

- A variety of shapes available – including open tubes, closed tubes, porous tubes, blind hole tubes, step tubes, rings, rollers, etc., and can be customized as required.

Alumina Ceramic Ring

Alumina ceramic rings are used as spacers, insulators, and sealing components. These alumina ceramic rings resist thermal shock and abrasion, making them ideal for pumps, valves, and electrical isolation in high-voltage systems.

Technical Specifications

| Parameter | Typical Range |

| Length Range | ≤300mm |

| Outer Diameter | ≤150mm |

| Surface Roughness | Ra0.02-Ra0.2 |

| Minimum Wall Thickness | 0.1mm |

| Roundness | 0.002mm |

| Concentricity | 0.002mm |

| Straightness | 0.004mm |

| Perpendicularity | 0.005mm |

Please refer to our Processing Capability Table for the full range of processing capability.

Advantages of Alumina Ceramic Ring

- High Hardness and Wear Resistance: Because alumina is extremely durable, the ring resists abrasion and maintains dimensional stability over time.

- Excellent Thermal and Chemical Stability: As a result, it performs reliably in extreme temperatures and corrosive environments.

- Electrical Insulation: Therefore, it’s ideal for use in high-voltage or sensitive electronic systems.

- Corrosion and Oxidation Resistance: In addition, it withstands exposure to acids, alkalis, and other aggressive substances.

- Precision Machinability: Thanks to advanced ceramic processing, alumina rings can be fabricated to tight tolerances and customized geometries.

- Biocompatibility: Consequently, they are safe for use in medical and food-grade applications requiring inert materials.

Applications

- Mechanical Seals and Bearings: For example, they are used in pumps and motors where wear resistance and thermal stability are essential.

- Electrical and Electronic Insulation: Because of their dielectric properties, they serve as insulating rings in connectors, sensors, and high-voltage assemblies.

- Medical and Laboratory Equipment: In addition, they are applied in centrifuges, mixers, and other devices that require chemical resistance and cleanliness.

- Semiconductor Manufacturing: These rings are used in wafer handling, plasma etching, and other high-purity, high-temperature processes.

- Aerospace and Defense Applications: Their stability and strength make them ideal for structural or insulating parts in demanding conditions.

- Chemical Processing and Fluid Systems: Lastly, they function as gaskets, spacers, or isolation components exposed to aggressive media.

Enquire Now

- Welcome to contact us for more product information and quotes!

- Support customization according to drawings, quick response, short delivery guarantee!

- Consult Now

English

English 中文

中文