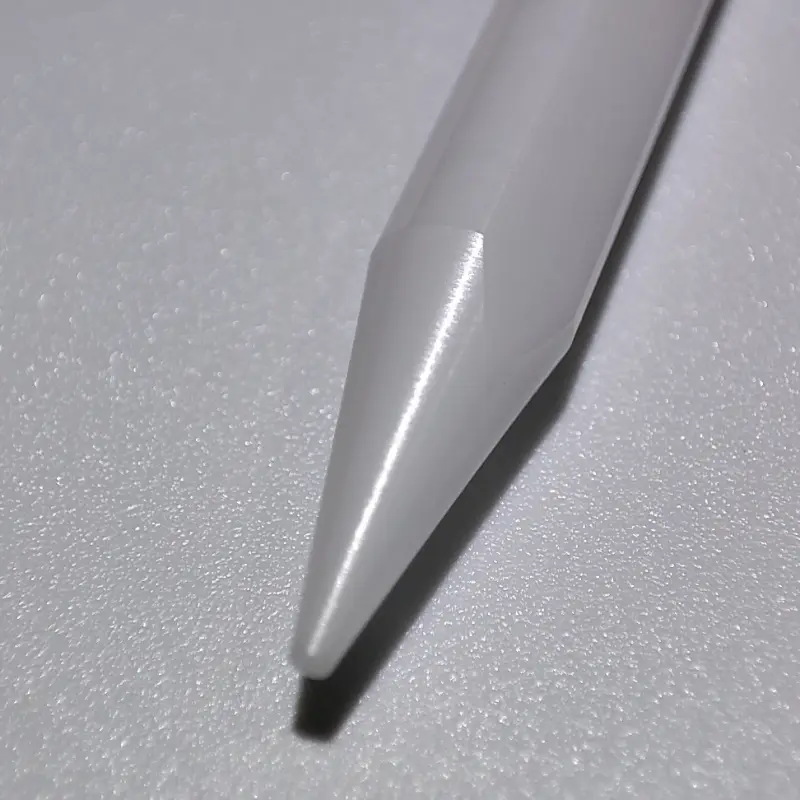

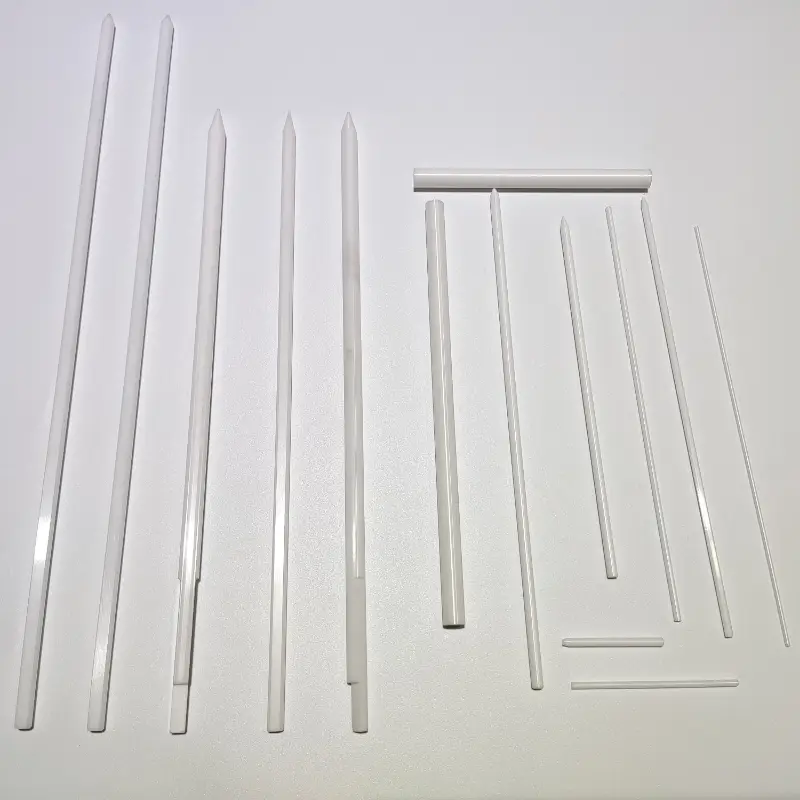

Ceramic Center Rod

Ceramic center rods provide precise positioning and easy demolding in mold manufacturing processes. Made from durable ceramic materials, they offer excellent wear resistance, thermal stability, and chemical inertness. Ideal for applications such as heat pipe molding and other precision forming tasks. Custom sizes and designs available. Applicable to: high temperature gas/liquid pipelines, protective sleeves, precision equipment pipe fittings, corrosion-resistant pipelines, etc.

- High wear resistance and mechanical strength

- Excellent thermal stability

- Chemical inertness for corrosion resistance

- Precise dimensions for accurate positioning

- Custom production available

Ceramic Center Rod

Zirconia center rods serve as axial supports and alignment elements in high-precision or high-temperature systems. These ceramic center rods are made from zirconia or alumina for excellent stiffness, wear resistance, and dimensional stability. They are used in fixtures, furnace setups, and measuring tools.

Technical Specifications

| Parameter | Typical Range (may vary for different shapes/materials) |

| Length Range | ≤1000mm |

| Outer Diameter | ≤150mm |

| Drilling-Minimum Hole Diameter | ≥φ0.4mm |

| Outer Diameter Precision | 1-25mm: ±0.002mm 20-50mm: ±0.003mm 50-100mm: ±0.050mm 100-150mm: ±0.100mm |

| Length/Thickness Precision | ±0.005mm |

| Surface Roughness | Ra0.03 |

Please refer to our Processing Capability Table for the full range of processing capability.

Advantages of Ceramic Center Rod

- High Mechanical Strength: Because ceramics offer excellent rigidity, the center rod provides reliable structural support under compression or tension.

- Outstanding Wear and Abrasion Resistance: As a result, it resists surface degradation in contact with other moving or abrasive components.

- Thermal and Chemical Stability: Therefore, it operates effectively in high-temperature and corrosive environments without degradation.

- Electrical Insulation: Thanks to its non-conductive nature, it can be used safely in high-voltage and electronic applications.

- Dimensional Precision: Consequently, it is ideal for applications requiring tight tolerances and consistent alignment.

- Material Inertness: This allows for safe use in sensitive environments, including medical, semiconductor, and analytical systems.

Applicable Industries

- Semiconductor & Electronics: Insulation protection tube, high temperature heating tube.

- Medical equipment: Bioceramic tube, corrosion-resistant temperature measuring sleeve.

- Chemical & Energy: Acid and alkali resistant fluid pipeline, catalytic reaction tube.

- Precision manufacturing: High hardness sleeve, wear-resistant annular tube.

Enquire Now

- Welcome to contact us for more product information and quotes!

- Support customization according to drawings, quick response, short delivery guarantee!

- Consult Now

English

English 中文

中文