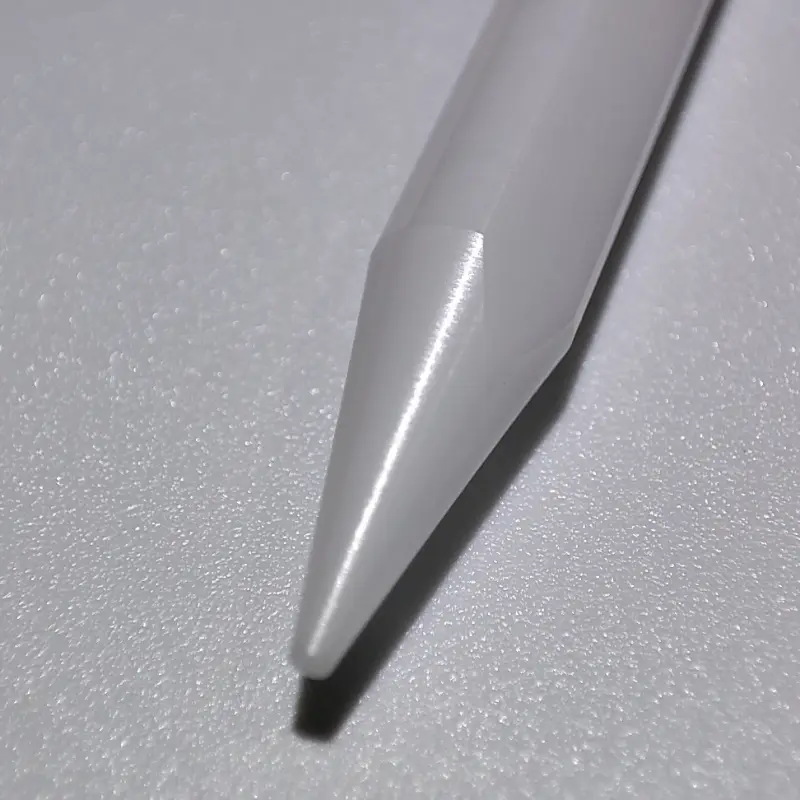

Ceramic Needle Gauge

Ceramic pin gauges are high-precision measuring tools made of zirconium oxide ceramics. They are hard, wear-resistant, chemically resistant, insulated and anti-magnetic, with a low thermal expansion coefficient. They are suitable for micron-level precision testing. Their surface is smooth and non-magnetic to avoid scratching workpieces or interfering with precision instruments.

Support customization, complete specifications!

- High hardness and excellent wear resistance

- Non-magnetic and electrically insulating

- Superior dimensional stability

- Ultra-smooth surface finish

- Custom production available

Ceramic Needle Gauge

A ceramic needle gauge is a high-precision measuring tool made from wear-resistant materials such as alumina or zirconia. Designed for diameter checking or clearance control, the ceramic needle gauge maintains dimensional stability, even after repeated use in harsh or abrasive environments. It is ideal for QA labs, mold inspection, and electronic manufacturing lines.

Technical Specifications

| Parameter | Typical Range (may vary for different shapes/materials) |

| Length Range | ≤1000mm |

| Outer Diameter | ≤150mm |

| Drilling-Minimum Hole Diameter | ≥φ0.4mm |

| Outer Diameter Precision | 1-25mm: ±0.002mm 20-50mm: ±0.003mm 50-100mm: ±0.050mm 100-150mm: ±0.100mm |

| Length/Thickness Precision | ±0.005mm |

| Surface Roughness | Ra0.05 |

Please refer to our Processing Capability Table for the full range of processing capability.

Advantages of Ceramic Needle Gauge

- High Wear Resistance: The ceramic material resists abrasion, making the gauge ideal for high-precision, repeated measurement tasks.

- Dimensional Stability: Maintains consistent accuracy even under thermal and mechanical stress.

- Corrosion and Chemical Resistance: Inert to most acids, alkalis, and solvents, enabling use in harsh or reactive environments.

- Non-Magnetic and Non-Conductive: Suitable for sensitive electronic or magnetic field environments.

- Sharp and Precise Tip: Enables extremely fine measurements and positioning for small or delicate components.

- Longevity and Reliability: Offers longer service life than metal counterparts with minimal performance degradation over time.

Applications of Ceramic Needle Gauge

- Precision Measurement Tools: Used in dial indicators, micrometers, and comparators for high-accuracy gauging.

- Electronics Manufacturing: Ideal for inspecting microelectronic components where metal contamination must be avoided.

- Medical Devices: Applied in quality control of medical components requiring sterile, non-reactive measurement tools.

- Semiconductor Industry: Employed in wafer inspection and microfabrication processes requiring ultra-precise gauging.

- Laboratory Instrumentation: Used in analytical and metrology devices for fine measurement in controlled environments.

- Watchmaking and Fine Mechanics: Supports precision measurement and assembly in micro-mechanical systems.

Enquire Now

- Welcome to contact us for more product information and quotes!

- Support customization according to drawings, quick response, short delivery guarantee!

- Consult Now

English

English 中文

中文