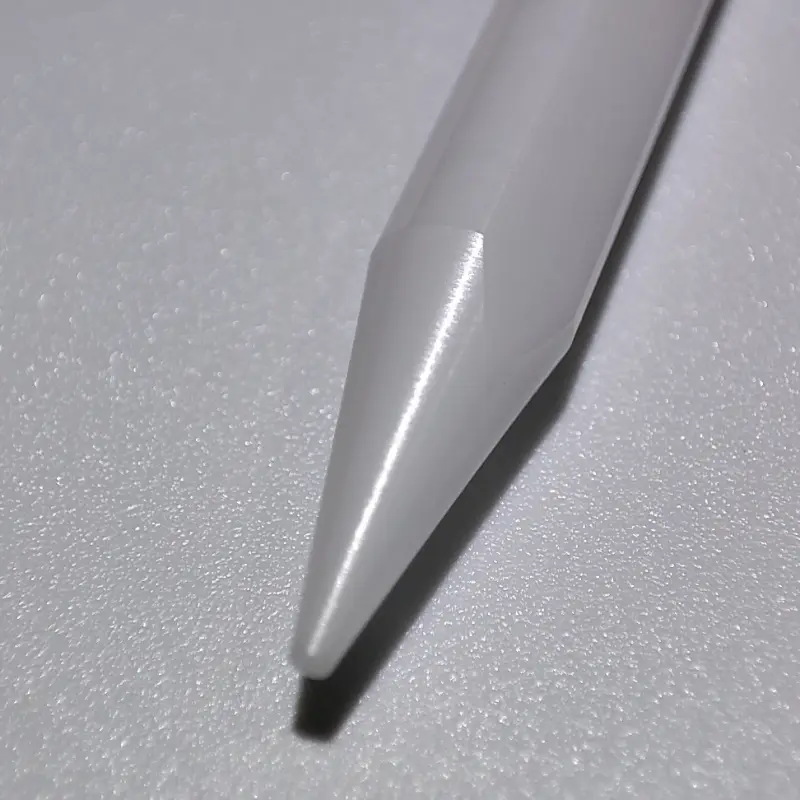

Ceramic Plunger

Ceramic plungers are durable components widely used in medical pumps and fluid control devices. Made from high-strength, corrosion-resistant ceramics, they ensure reliable sealing, wear resistance, and long service life in demanding environments. Custom designs and sizes available to meet specific application requirements. Support customization, complete specifications!

- Superior hardness and wear resistance

- Chemical and corrosion resistance

- Excellent sealing and dimensional stability

- Thermally stable under varying temperatures

- Custom production available

Ceramic Plunger

Zirconia plunger ensures tight seals, low wear, and chemical resistance in medical or fluid systems. This ceramic plunger, typically made from alumina or zirconia, provides long-lasting performance in metering pumps, valves, and analytical devices under corrosive conditions.

Technical Specifications

| Parameter | Typical Range (may vary for different shapes/materials) |

| Length Range | ≤1000mm |

| Outer Diameter | ≤150mm |

| Drilling-Minimum Hole Diameter | ≥φ0.4mm |

| Outer Diameter Precision | 1-25mm: ±0.002mm 20-50mm: ±0.003mm 50-100mm: ±0.050mm 100-150mm: ±0.100mm |

| Length/Thickness Precision | ±0.005mm |

| Surface Roughness | Ra0.05 |

Please refer to our Processing Capability Table for the full range of processing capability.

Advantages of Ceramic Plunger

- High Wear and Abrasion Resistance: Because of its extreme hardness, the ceramic plunger delivers excellent durability in high-friction environments.

- Chemical Inertness: Therefore, it remains unaffected by aggressive fluids such as acids, alkalis, or solvents.

- Thermal Stability: As a result, it maintains performance and dimensional accuracy even under fluctuating or elevated temperatures.

- Low Friction Coefficient: Consequently, it reduces wear on mating parts, ensuring smoother operation and longer component life.

- Corrosion Resistance: In addition, its resistance to oxidation and chemical attack makes it ideal for use in harsh processing systems.

- Precision Machining Capability: Thanks to advanced ceramic fabrication, plungers can be manufactured with extremely tight tolerances.

Applications of Ceramic Plunger

- Medical and Laboratory Pumps: For example, they are widely used in high-precision syringe pumps and fluid dispensers requiring purity and chemical resistance.

- Food and Beverage Equipment: Because of its inertness and cleanliness, it is used in dosing systems for sanitary fluid handling.

- Chemical and Pharmaceutical Processing: In addition, ceramic plungers are ideal for metering and injection pumps that handle corrosive or reactive substances.

- Industrial Metering Systems: These components maintain reliable flow control in high-pressure and high-wear environments.

- Inkjet and Printing Machinery: Since they ensure consistent ink flow and resist abrasion, ceramic plungers are critical in high-speed, long-life applications.

- Semiconductor and Electronics Manufacturing: Lastly, they are used in ultrapure fluid systems where contamination and degradation cannot be tolerated.

Applicable Industries

- Semiconductor & Electronics: Insulation protection tube, high temperature heating tube.

- Medical equipment: Bioceramic tube, corrosion-resistant temperature measuring sleeve.

- Chemical & Energy: Acid and alkali resistant fluid pipeline, catalytic reaction tube.

- Precision manufacturing: High hardness sleeve, wear-resistant annular tube.

Enquire Now

- Welcome to contact us for more product information and quotes!

- Support customization according to drawings, quick response, short delivery guarantee!

- Consult Now

English

English 中文

中文