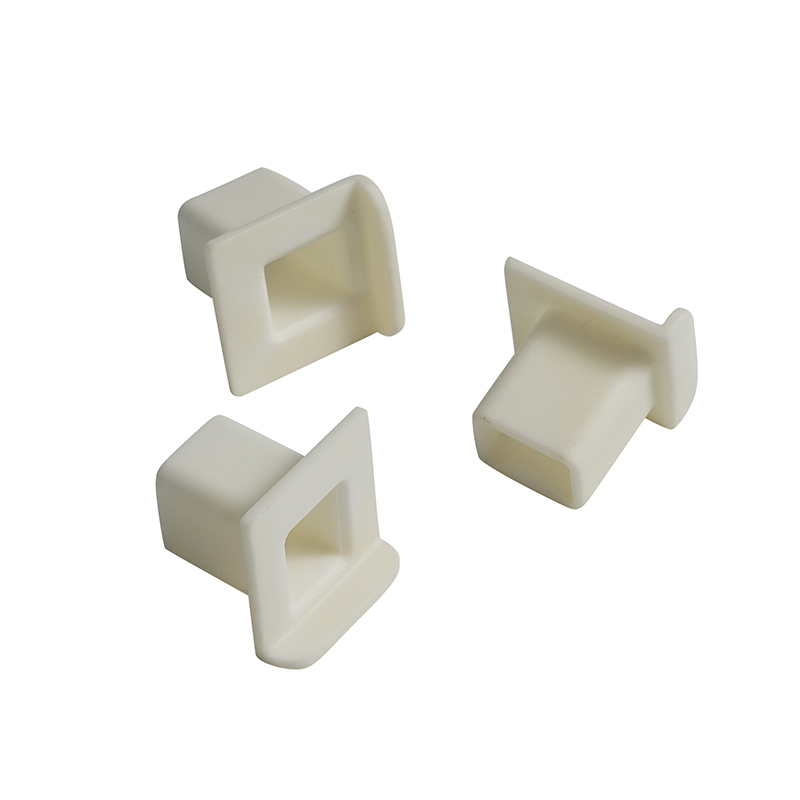

Complex Alumina Component

Complex Alumina Components, crafted from high-purity alumina, feature intricate designs for industrial and medical applications. With precision engineering, they offer durability, corrosion resistance, and custom configurations for specialized needs.

- High-Purity Alumina: Offers excellent heat and corrosion resistance.

- Precision Engineered: Ensures accurate complex geometries.

- Customizable Design: Tailored to specific industrial or medical requirements.

- Durable Performance: Ideal for harsh environments and long-term use.

- Versatile Applications: Suitable for industrial and medical sectors.

Complex Alumina Component

Complex alumina component is engineered to meet application-specific tolerances and performance needs. These alumina ceramic parts serve across industries such as semiconductors, medical devices, and machinery, providing insulation, strength, and thermal resistance.

Technical Specifications

| Parameter | Typical Range |

| Length Range | ≤300mm |

| Outer Diameter | ≤150mm |

| Surface Roughness | Ra0.02-Ra0.2 |

| Minimum Wall Thickness | 0.1mm |

| Roundness | 0.002mm |

| Concentricity | 0.002mm |

| Straightness | 0.004mm |

| Perpendicularity | 0.005mm |

Please refer to our Processing Capability Table for the full range of processing capability.

Advantages of Complex Alumina Component

- Highly Customizable Geometry: Thanks to advanced ceramic forming and machining, alumina components can be manufactured in intricate shapes with tight tolerances.

- Excellent Mechanical and Thermal Strength: As a result, they maintain performance in structurally demanding and high-temperature environments.

- Outstanding Wear and Corrosion Resistance: Consequently, these parts last longer in abrasive or chemically aggressive settings.

- Electrical Insulation Capabilities: Because of their high dielectric strength, they are ideal for components requiring electrical isolation.

- Stable Performance Under Load and Heat: Therefore, they are suitable for dynamic systems that operate under mechanical and thermal stress.

- Material Purity and Compatibility: Particularly important in cleanroom or biomedical environments, alumina is inert and non-contaminating.

Applications

- Semiconductor Fabrication Equipment: Used in wafer chucks, insulators, and alignment parts where both complexity and cleanliness are essential.

- Medical Devices and Diagnostics: Ideal for housings, interfaces, and supports in precision medical instruments due to biocompatibility.

- High-Voltage Electrical Systems: Applied as insulators, spacers, or bushings in custom geometries to fit compact, high-power designs.

- Aerospace and Defense Assemblies: Because of its strength and precision, used in structural components exposed to vibration, heat, and stress.

- Industrial Machinery and Automation: Integrated into guide plates, nozzles, or sealing components that require complex design and high durability.

- Analytical and Laboratory Equipment: Suitable for high-purity, high-accuracy applications where thermal or chemical stability is vital.

Enquire Now

- Welcome to contact us for more product information and quotes!

- Support customization according to drawings, quick response, short delivery guarantee!

- Consult Now

English

English 中文

中文