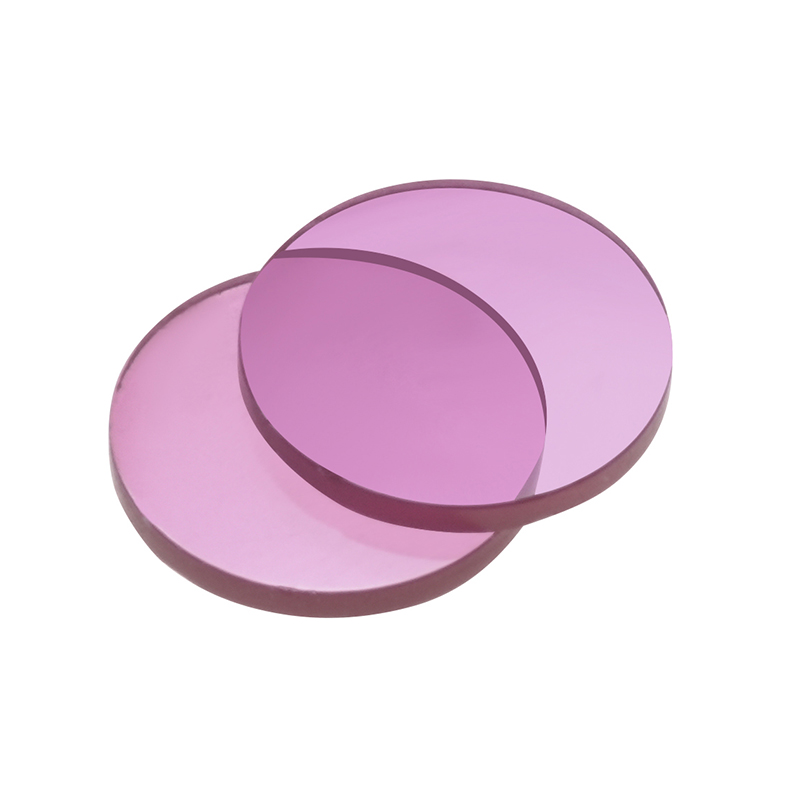

Industrial Ruby Disc

High-purity industrial ruby discs designed for precision mechanical or optical use. Known for outstanding hardness, chemical resistance, and low friction. Ideal as limiters, spacers, or wear-resistant components in demanding environments. Custom sizes and tolerances are available to meet specific application needs.

- Extreme hardness for long-lasting durability

- Excellent thermal and chemical stability

- Ultra-smooth surface for low-friction contact

- Precision flatness and tight tolerances

- Fully customizable in size, shape, and finish

Industrial Ruby Disc

Ruby ceramic chip is a compact, high-precision component made from synthetic ruby, known for its extreme hardness, dimensional accuracy, and optical clarity. These industrial ruby ceramic chips are widely used in sensor assemblies, metrology equipment, and high-precision motion control systems where wear resistance and stability are critical. The chip’s surface finish and hardness enable reliable contact, alignment, and positioning over extended operating cycles, even in abrasive or high-frequency environments.

Technical Specifications

| Parameter | Typical Range (may vary for different shapes/materials) |

| Size Range | ≤100mm × 100mm |

| Thickness Precision | ±0.005mm – ±0.05mm |

| Surface Roughness | Ra0.2 – Ra0.05 |

Please refer to our Processing Capability Table for the full range of processing capability.

Advantages of Industrial Ruby Disc

- High Hardness and Wear Resistance: Because ruby is a corundum material rated 9 on the Mohs scale, the disc resists scratching, wear, and surface damage under harsh conditions.

- Excellent Dimensional Stability: As a result, it maintains precise thickness and flatness over time, even under thermal or mechanical stress.

- Low Friction Surface: Consequently, it reduces drag and heat generation when in contact with moving parts or fluids.

- Chemical Inertness: Therefore, it withstands exposure to acids, alkalis, and solvents without degradation.

- High Temperature Tolerance: Thanks to its thermal stability, the disc operates reliably in elevated-temperature applications.

- Optical Transparency and Aesthetic Appeal: Although primarily functional, ruby’s transparency and color can also benefit visual or sensor-based applications.

Applications of Industrial Ruby Disc

- Precision Instrumentation: Used in pressure gauges, flow meters, and dial indicators for their smooth, stable, and wear-resistant surfaces.

- Medical Devices: Ideal for components in diagnostic tools or surgical instruments that require low friction and chemical resistance.

- Fluidic and Dispensing Systems: Serves as a control or sealing element in systems handling aggressive or ultra-pure liquids.

- Watchmaking and Timekeeping: Employed in balance wheels or movement bearings where wear resistance is critical.

- Optical and Sensor Equipment: Applied in devices where the disc functions as a light path or protective cover requiring durability.

- Scientific and Laboratory Instruments: Integrated into platforms or interfaces exposed to corrosive chemicals, repeated motion, or precision measurement.

Enquire Now

- Welcome to contact us for more product information and quotes!

- Support customization according to drawings, quick response, short delivery guarantee!

- Enquire Now

English

English 中文

中文