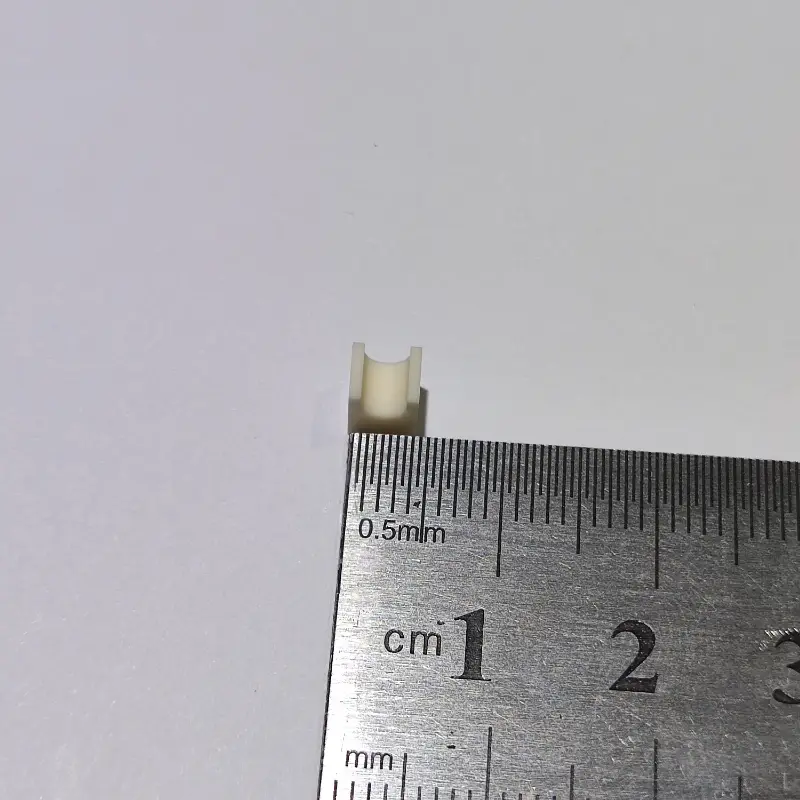

Miniature Zirconia Ceramic Square Rod

This zirconia ceramic square rod features a cross-section of just 0.3×0.3 mm, offering excellent structural rigidity and stability in ultra-compact assemblies. At such micro dimensions, metals tend to bend or deform, while zirconia maintains its shape and performance, making it ideal for precision applications in electronics, medical devices, and micro-mechanical systems.

- Extreme precision and micro-scale stability

- High strength and stiffness at sub-millimeter size

- Wear and corrosion resistant

- Electrical insulation and thermal resistance

- Custom micro-scale fabrication supported

Miniature Zirconia Ceramic Square Rod

Micro zirconia rod delivers high strength, tight dimensional control, and wear resistance in compact assemblies. These micro zirconia square rods are used as spacers, guide pins, or alignment blocks in electronic devices, sensors, and miniature mechanisms. The square geometry provides anti-rotation stability and uniform contact in constrained layouts. Their excellent hardness and chemical resistance ensure longevity in precision microfabrication environments.

Technical Specifications

| Parameter | Typical Range |

| Length Range | ≤300mm |

| Outer Diameter | ≤150mm |

| Surface Roughness | Ra0.02-Ra0.2 |

| Minimum Wall Thickness | 0.1mm |

| Roundness | 0.002mm |

| Concentricity | 0.002mm |

| Straightness | 0.004mm |

| Perpendicularity | 0.005mm |

Please refer to our Processing Capability Table for the full range of processing capability.

Advantages of Miniature Zirconia Ceramic Square Rod

- High Fracture Toughness and Strength: Because zirconia exhibits superior toughness, the rod resists cracking and mechanical failure even in small dimensions.

- Excellent Wear and Abrasion Resistance: As a result, it maintains its shape and surface quality under frequent or high-friction use.

- Thermal and Chemical Stability: Therefore, it remains dimensionally stable and chemically inert in harsh or variable environments.

- Tight Dimensional Tolerances: Thanks to advanced precision machining, the rod can be manufactured to exacting specifications for critical fits.

- Non-Magnetic and Electrically Insulating: Consequently, it’s well-suited for applications requiring electrical isolation or use in magnetic-sensitive environments.

- Small Cross-Section Versatility: Due to its strength even at micro sizes, it supports applications where space constraints and fine control are critical.

Applications

- Medical and Dental Devices: Used in micro-instruments, surgical tools, or implants requiring strength, biocompatibility, and precision.

- Micro-Electromechanical Systems (MEMS): Ideal for small-scale actuation or support components in sensors or microfluidic systems.

- Precision Measuring Instruments: Serves as reference rods or guides where dimensional accuracy and wear resistance are vital.

- Semiconductor and Electronics Manufacturing: Applied in alignment tools, chip handling devices, or as insulating standoffs.

- Optical and Laser Equipment: Provides stable, non-reflective mounting or spacing in compact, light-sensitive setups.

- Research and Laboratory Applications: Used in high-precision assemblies or sample holders requiring strength and chemical resistance at micro-scale.

Enquire Now

- Welcome to contact us for more product information and quotes!

- Support customization according to drawings, quick response, short delivery guarantee!

- Consult Now

English

English 中文

中文